1. Dial Resolution versus Tuning Accuracy

and the GPR-90

- Although most reviewers rate the GPR-90 dial accuracy as "excellent"

or "very good," it does depend on exactly what is considered "accurate."

There is a difference between "accurate" and then having usable dial

resolution. After alignment, most analog dial receivers will be accurate

on "marker" frequencies. That would be tuning in known frequency

stations such as WWV. Dial resolution allows an "accurate" receiver to

tune "to the kilocycle" since the dial can resolve frequency to the

accuracy of one

kilocycle. The Collins 75A and 51J receivers were analog dial tuning

systems that could accurately resolve frequency "to the kilocycle." Any receiver

that covers several megacycles in each of its selected tuning ranges

isn't going to have a reasonable-size tuning dial that can resolve to the kilocycle.

AND, add to that,...any receiver that has a Bandspread variable-C tuning in

parallel with

the Main Tuning variable-C tuning is going to have potential dial readout accuracy

problems. And, that goes for both dials. The 100kc Calibrator found on

most GPR-90 Series receivers can be used to accurately set-up the Bandspread

dial but the resolution is still somewhat limited (the very best

resolution is on the BS 160M band where the index marks are in 5kc

increments.) Also,

using the 100kc Calibrator, the Main Tuning dial can sometimes be

accurately set-up using the Bandspread dial for a frequency-trim adjustment.

But, sometimes the Main Tuning calibration reads lower than desired with

the BS set to 100. In that particular condition, the BS can't be used to

"trim in" the Main Tuning dial calibration (RF tracking

alignment needed.)

|

2.

GPR-90 tuning system uses "Pinch-Wheel"

drives - The

Hammarlund Super Pro Inspiration - The WWII Hammarlund Super Pro

seems to have been the "model" that TMC chose for designing the tuning

system used in the GPR-90. The dial layout versus placement of the

S-meter follows the WWII Super-Pro and many of the Hammarlund HQ-models.

The pinch-wheel, rim drive dial tuning system, including the dial

guides, are exactly like those used in the 1935 to 1949 Hammarlund

Super-Pro receivers (before the SP-600.) As to why TMC copied the WWII

Super-Pro in 1955 when it was obvious then that even the "new" Hammarlund

SP-600 was a "dated" design when compared to the receivers designed and

produced by Collins, is a mystery. It does seem like the TMC mechanical engineers

were copying designs that were already two decades old,...but, certainly

the cost factor must have been an important consideration on TMC's part.

But, even Hammarlund never changed their dial drive system on the Super

Pro from 1935 up through the 1947 SP-400-X shown to the right. |

Hammarlund - Super-Pro SP-400-X |

|

National Co. - NC-183D |

Incidentally, the National NC-183D also used a pinch-wheel rim-drive

tuning as did the Hammarlund HQ-180,...probably because when all of the

parts are in good condition and clean, this design results in very

smooth tuning and an excellent tuning ratio reduction in the drive. In

fairness to the NC-183D, those are edge-illuminated Lucite dials mounted

to copper-plated metal backing plates and the pinch-wheel actually works

against the metal backing plate that then drives the main or bandspread

tuning condensers through a gear-reduction set up,...a first

class mechanical design. While the NC-183D certainly won't win

any "beauty contests," it's no slouch when it comes to

performance. And, the NC-183D has one of the best audio

reproduction circuits found in a communications receiver. But, an

additional benefit was the selling price of just $385 in 1954.

The price did increase into the $400 range by the late-fifties.

On the downside, a lot of NC-183D receivers seem to have had

their original power transformers replaced with non-OEM units. |

|

Another direct-to-plastic dial "pinch-wheel" drive

tuning system with the two dials flanking the S-meter that was

contemporary with the GPR-90 was a creation

from National after they had changed their receiver manufacturing name to

"National Radio Company." That receiver was their cheaply

made and grossly over-priced NC-400. Without a doubt, the GPR-90 was a

better-built and better-looking receiver that could easily

out-perform National's NC-400 and only cost half the price. And,

when it came to "ugly," the NC-400

had few peers.

The Hammarlunds, the NC-400

and TCM all used a pinch-wheel to drive the rim of the plastic dial rim

directly. Dial warping and delaminating were sometimes problems on the pre-WWII designs but

post-WWII plastics were much better at resisting warping or other issues, so it's

usually not a problem to drive the plastic rim directly on these later

receivers.

3. Sunburned Dials?

- Although the plastic used for the dials pre-WWII was

particularly photo-sensitive and darkened with exposure to

excessive light, after WWII the plastics were much more

resistant to "sunburn." Normally, the GPR-90 dials won't

discolor from moderate exposure sunlight.

However, I did recently

inspect a GPR-90R receiver that had a very noticeable tan discoloration that was

limited to the portion of the dial that had been exposed to excessive sunlight

through the dial bezel opening. This discoloration was on both the main

dial and the bandspread dial. It's a seldom seen problem on the GPR-90

receivers,...but it

can happen. |

National Radio Co. - NC-400 |

|

4. TMC's Defense Regarding

Tuning Accuracy - TMC seemed to get somewhat irritated

whenever the GPR-90's tuning resolution was criticized. TMC actually

published testy comments in their service bulletins (SUP-1 GPR 9-56) defending the variable-C

tuning with analog dials against the "to the kilocycle

accurate" Collins tuning systems. The TMC arguments were, "The

GPR-90 is a general coverage receiver, and a real good

one, but it is NOT a frequency meter." This was followed by,

"People who require frequency meters should buy frequency meters - not

make them double as communications receivers." These are certainly the best known

of their peevish comments that all seem to be directed precisely at TMC's

"big-time" military contract competitor, Collins Radio Company. However, TMC's comments do illustrate that when

comparing the GPR-90RXD to the Collins R-388 in an unbiased evaluation,

maybe there's something to be considered besides tuning accuracy. TMC

probably thought that really ALL the R-388 offered the end-user

was essentially a frequency meter that happened to also work as a

receiver. Beyond the R-388's front-end, the rest of the receiver's

circuitry is standard and in some places actually deficient in

performance, e.g., the detector, the AVC, the noise limiter and even the

audio quality. So, maybe if the R-388 was looked at "critically" then

TMC probably had a point in their "frequency meter" comparisons.

Nowadays, 65+ years later, when vintage equipment from either company

can be easily found, rebuilt and used, we have a different perspective

on vintage receiver performance and TMC's comments advocating buying a

heterodyne frequency meter to go with your GPR-90 receiver seems kind

of humorous,...although I don't think it was originally intended to be.

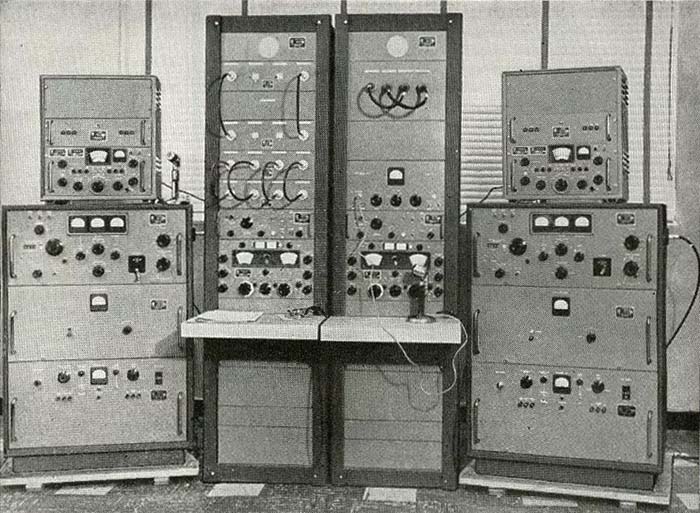

As an aside,...Beckman/Berkeley must have taken TMC's "freq meter"

comments "to heart" because one of their products was an elaborate

Beckman Frequency Measuring System that

had a Collins 51J-4 receiver (Beckman/Berkeley Model 7700) as the main component of the instrument.

The Beckman Frequency Measuring System is shown in the photo to

the right. Beckman extensively modified the 51J-4 to work with the

ancillary equipment in the system. Additionally, a new front

panel was made for the receiver. Note that the 51J-4 receiver

doesn't have a CALIBRATE function (100kc crystal oscillator.) |

Beckman Frequency Meter |

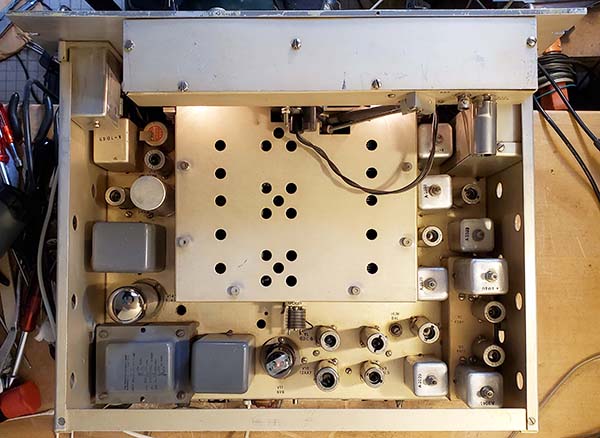

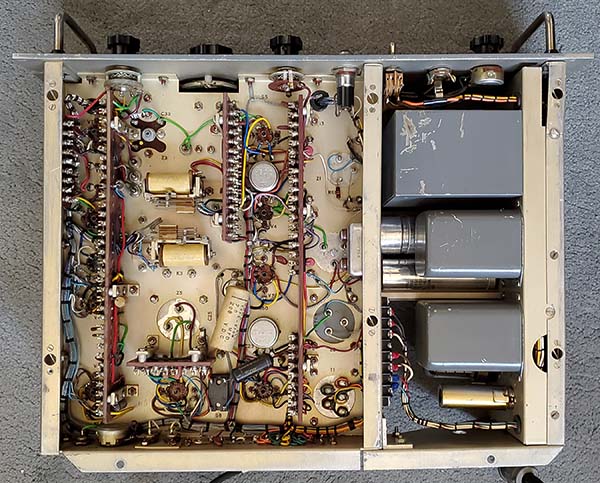

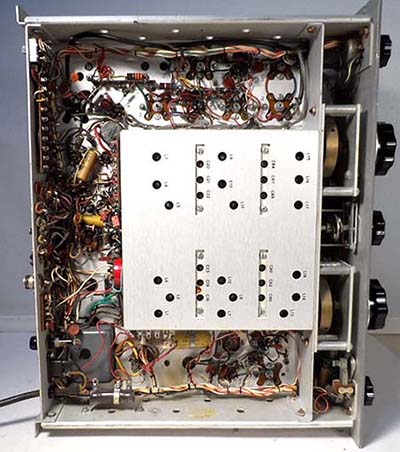

5. Cheap Construction?

A Mechanical Design Flaw or two? - This appears to be a common complaint but most reviewers are comparing

the GPR-90 to other more expensive, built-for-the-military (or

government) TMC products or to other expensive

Collins military receivers. Hardly a fair comparison. The passive components used in the GPR-90 receivers appear to be excellent quality. Ceramic disk capacitors

are used throughout the receiver circuitry. A-B resistors are used

throughout. Component boards are used in

a few locations to reduce chassis component congestion and to provide a

better mounting platform for the circuitry. The build quality seems

to be better than average if the GPR-90 is actually compared to

other $400 to $500 receivers built for the ham market. That price would

put the GPR-90 mid-way between a Collins 75A-4 on the high end (about

$695) and a National NC-183D on the low end (about $385.) The GPR-90

sheet metal fit and finish are quite

good with the exception of the mounting of the AUDIO SELECTOR switch

housing that's behind the front panel. Typically, the shield-can will

interfere with the rotation of the bandspread dial. A slightly askew

mounting of the can usually will provide enough clearance (I did see

one GPR-90 that had the shield-can entirely removed.) The GPR-90 table cabinet is steel construction, very heavy

(about 25 pounds) and painted a gorgeous medium blue wrinkle finish paint.

The cabinet has a very low height compared to the usual 1950s cabinets (of

course, that's an opinion, isn't it?) The next mechanical problem is more

serious,...

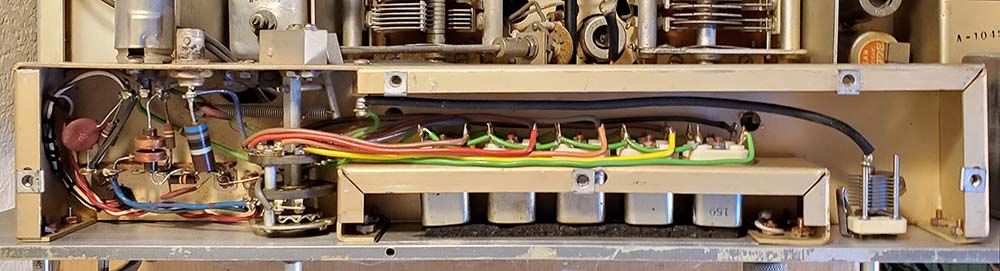

6.

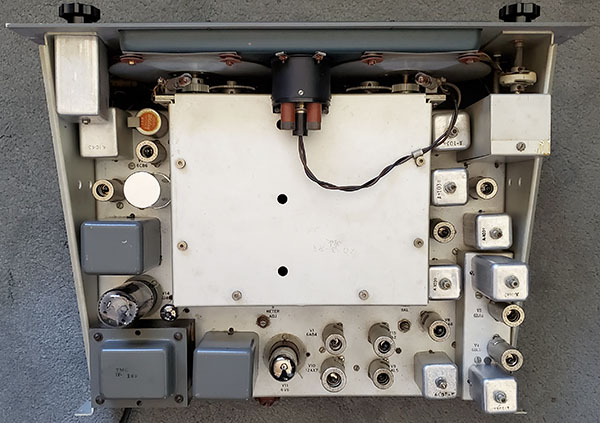

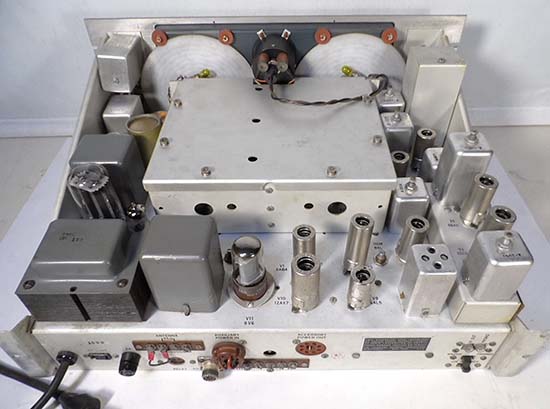

IMPORTANT NOTE about Potential Coil Form Damage: The

ceramic coil forms used in the GPR-90 front end are fragile and can be

easily broken. When the GPR-90 is removed from its cabinet for repair or alignment,

it's very important to first place the receiver chassis on its side.

Then check the RF coil box under the chassis to examine how far any of the

L-slug adjustment threaded rods protrude through the holes out past the

surface of the RF

coil box cover. This cover is usually flush with the height of the

chassis but the front panel does extend below the chassis line. If the

receiver is placed on a workbench right-side up with the front panel

bottom edge also on the workbench there is usually sufficient

clearance for the L-slug rods since there is some chassis elevation from

the front panel bottom edge being slightly higher than the bottom

chassis line.

However, the result of placing the receiver chassis on the workbench

right-side with the front panel "hanging over" the workbench edge might

cause interference for any L-slug rods that protrude out the coil box by

putting pressure from the chassis weight directly on any

protruding L-slug adjustment rods. This can easily break the fragile ceramic coil forms

inside the RF coil box. Sliding the chassis onto the workbench can be a

disaster for any protruding L-slug rods and their associated ceramic

coil forms. If some of the L-slug adjustment rods are extending through

the cover holes then the chassis will have to set with either the front

panel bottom edge on the bench, but it's better to use some spacer

blocks to elevate the chassis off the workbench surface to protect the ceramic coil forms from damage when it's

right-side up on the bench. When the GPR-90 was new and aligned

correctly, none of the L-slug adjustment rods protruded out

through the holes but after decades of questionable maintenance, sloppy

alignments and

possibly

component aging sometimes a few of the rods will be protruding. Check

to be sure where the L-slug rods are before setting the chassis onto the workbench right-side up.

NOTE: Gerry O'Hara

VE7GUH, in his GPR-90 write-up, mentions the possibility that when the

chassis is either removed or replaced into the cabinet that the L-slug rods

could catch on the lip of the cabinet and cause the damage to the

ceramic coil forms. A link to Gerry's article is provided at the end of

this write-up in "References."

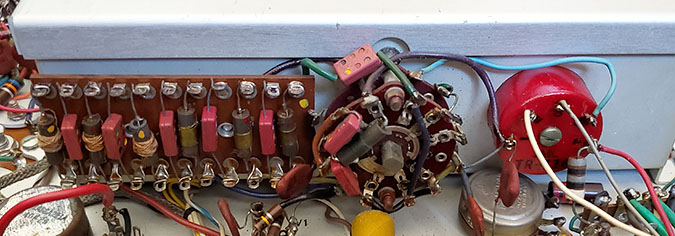

7. Mechanical Maintenance and

Disassembly Issues

- If and when any type of GPR-90 receiver is extensively disassembled it

becomes apparent that maintenance wasn't at the forefront of the

mechanical design considerations. The TMC mechanical engineers seemed to believe the receiver

would NEVER need to be disassembled for any reason. Almost all assembly

uses screw, lock-washer and nut mountings and then the fasteners are

coated with GLPT. No pem-nuts are used and only the front panel bezel

has its screws threading into tapped holes. Top and bottom coil

box/tuning condenser covers are mounted with machine screws threading

into clip nuts. Additionally, some of the wiring assembly technique used very tight lead wraps that

were generally at least two

full wraps in, through and around the terminal eyelets. This makes any

defective component removal much more difficult than it should be with the possibility of

collateral damage also occurring (this is assuming the technician

isn't just going do a "clip and wrap" job.) This

electronic assembly technique, along with excessive torque used during

the mechanical construction, results in a receiver that's difficult to

disassemble without inflicting some collateral damage (one time I actually

broke the tip off of a "ball-tip" Allen wrench trying to loosen a

GPR-90 bandswitch knob set screw,...unbelievable.)

8.

Crystal Filter Not Selective Enough

- This is another common complaint that seems rooted in comparisons to

either modern receivers or to receivers equipped with Collins mechanical

filters. The GPR-90 Crystal Filter is the only control that the

operator has over the bandwidth. One has to wonder if the reviewers

actually adjusted the PHASING control for minimum bandwidth or

heterodyne attenuation or if they just expected that the bandwidth

showing on the switch nomenclature just "happened." Like any

standard Crystal Filter, the GPR-90's can also eliminate adjacent

frequency SSB "chatter" quite well but one does have to adjust the

PHASING somewhat off of minimum bandwidth to accomplish that. The NON XTAL position will have about 7kc

bandwidth at -6db. There are also a couple of audio filters that can be

utilized, one for voice operations and one for CW operations. On the whole, the GPR-90 is a little better

than most of its similarly priced competition for selectivity options (and

at least it doesn't have a Q-multiplier for a selectivity control!)

9. Not Mechanically Stable

- Another common complaint that certainly does have some merit,...but then,

how many people bang on the side of their receiver just to see what

happens? At any rate, there are a few things that contribute to the

mechanical instability issue and that would be that the coils mount on and

under the chassis directly below the tuning condensers that mount on the

top of the chassis. Any flexing of the chassis will skew the tuned

frequency by the mechanical movement of the LC involved. It's a common

problem in ALL receivers that are variable-C tuned with L coils mounted on

common chassis. When the receiver was mounted in a communications rack,

there wasn't access for the operator to reach in and "flex" anything, so

it's kind of a mute point when the receivers were properly installed and

properly used (and there are dial locks on both dials that could be

utilized.) However, mechanical instability problems that are

abnormal

can usually be traced to the "all too common" maintenance

technician practice of not

installing all of the shielding and not installing all of the screws,

washers and nuts. Mechanical stability did require that all of the

assembly mountings were secure and tight. Leaving

out screws (and even leaving out shields and covers) was a common occurrence with some types of maintenance

technicians. Also, component replacement soldering problems can be a

cause of instability. The receiver is assembled in such a manner that

component replacement is difficult to do correctly. Some technicians

would just "clip, wrap and solder" to replace defective components

resulting in sloppy-looking and operationally-questionable solder joints. Wholesale

capacitor replacement isn't necessary on the GPR-90 because of the

ceramic disk capacitors used but the filter capacitor and a couple of

the other electrolytics might have installation problems. Also, it was

common to have to replace the power transformer and proper soldering

with that installation would be very important. So, there

are lots of ways to create your own mechanical instability problems.

Also, sometimes instability can come from very simple problems that can

easily be solved, like just cleaning the variable-Cs, the bandswitch

contacts, the tube sockets contacts, etc. When

in excellent condition, with minimal mechanical wear and with a

competent going over of what really needs to be rebuilt or

replaced, the GPR-90 is as stable as,...say,...the Hammarlund HQ-180 or the

National NC-183D.

10. Demodulating SSB

Signals can be

Difficult, Maybe Impossible - A common complaint mainly from users that

expect to find a Product Detector in the GPR-90 receiver that would allow the

operator to have the RF Gain at maximum and the AVC on and demodulate

SSB signals with low distortion. But, the standard GPR-90, even with its

diode detector, can demodulate SSB

signals easily but it requires a reduction in the RF Gain level to

achieve the proper ratio of signal level to BFO injection level at the receiver

detector (also AVC can be switched off for better adjustability.)

Demodulating any SSB signal is easy so no particular difficulty

should be encountered IF the receiver is functioning correctly. The standard GPR-90 circuit uses a 15pf BFO

coupling capacitor and that is a large enough value to provide a good level of BFO

injection. The GPR-90RX receiver uses the same BFO circuit as the

GPR-90, so the BFO coupling capacitor is 15pf. The GPR-90RX will

demodulate SSB with the same ease as the standard GPR-90. This isn't the

case with the GPR-90RXD,...

For a "stand alone" GPR-90RXD, with its very low level of BFO injection, tuning in

almost any SSB signal is very difficult, maybe even impossible since the BFO coupling capacitor is just 3pf.

Even reducing the RF Gain doesn't help because the receiver becomes

desensitized before the received signal level to BFO injection is correct. The

only method for SSB reception with a stock GPR-90RXD is to use a MSR SSB

Adapter. It's possible that TMC intended that all

GPR-90RXD receivers that weren't in diversity set-ups would be set up with MSR SSB Adapters and therefore

the low-level BFO injection in the receiver didn't matter since all CW

and SSB signals would use the MSR adapter. It's also possible that the

low BFO injection level may have had something to do with diversity

reception and the receiver's BFO might have only been used for testing

and multiple receiver balancing set-ups for diversity operations. In all normal diversity reception,

regardless of the mode, the

receiver's BFO would be off and the receiver's AVC would be on.

Reducing the level of RF gain to adjust the ratio of signal input

level to BFO injection was standard procedure for CW reception

with almost all

superheterodyne communications receivers, from the 1930s up into the early-1950s. When SSB signals came along in the mid-fifties, this adjusting the BFO

injection to signal level ratio also applied to demodulating the "new SSB

signals." At that

time most

hams still had older receivers with diode detectors so to get the proper BFO

ratio they reduced

the RF Gain so the SSB signals would demodulate correctly. Some hams

went further and upped the BFO injection by increasing the value of the BFO coupling

capacitor. Later, modifications for a product detector to replace the

diode detector came on the scene. Although the standard GPR-90 doesn't

really have any difficulty demodulating SSB signals, the standard GPR-90 manual (in Section

7) suggests that the value of C59, the BFO coupling C, can be increased for better SSB

demodulation. I haven't changed the 3pf BFO cap in my GPR-90RXD

because it came with its

matching (same serial number) MSR-6 SSB Adapter. The MSR-6 (or any

compatible TMC SSB Adapter) makes all the difference in copying SSB

or CW

effectively with the GPR-90RXD. The MSR provides another IF conversion (455kc

to 17kc) along with a product detector and

its own BFO.

More details on the MSR-6 further down this article in the "TMC SSB

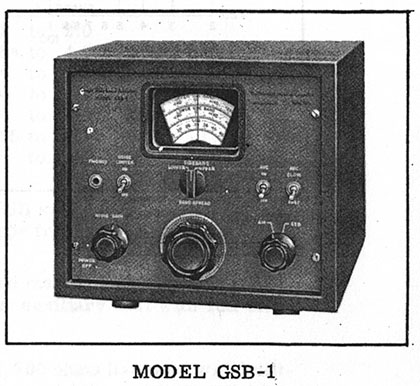

Adapters" section. The GSB-1 SSB Adapter would also provide a nice improvement

in SSB and CW reception capabilities for the standard GPR-90 with the

additional IF conversion of 455kc to 17kc, its own BFO and a product

detector. But the

GSB-1 is a rare and expensive (and not essential) accessory for the standard GPR-90 (even

the USN CV-591A SSB Adapters are now selling at about the same price as a R-390A receiver!)

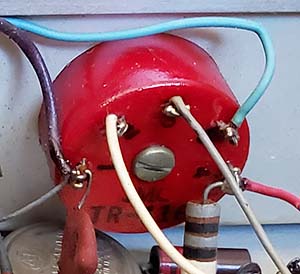

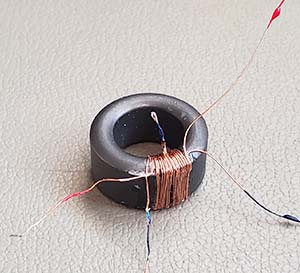

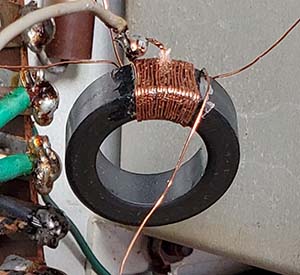

11. The

Ferrite Core Z-matching Transformer - The GPR-90's Achilles' Heel

- Maybe it's just me but it seems that a large number of GPR-90

receivers are either missing the Z-matching antenna input transformer or

the one that's still in the receiver is defective. Unless there's some

protection provided to the antenna input, any RF, even from a relatively

low power transmitter, or a powerful pulse energy field (near lightning

strike,) getting to the 75Z or 300Z inputs will have a direct path

through a few turns of #30 magnet wire to chassis-ground. An

arc inside a misadjusted Dow-Key relay could provide sufficient RF to

overheat the Z-matching transformer windings which changes the

characteristics of the wire and the relationship of the primary to

secondary. This can result in either an open circuit primary or a

shorted primary to secondary. A nearby lightning strike might also

provide sufficient energy to overheat T1 with similar results. Large

array antennas in dry wind storms can generate very high levels of

static charges that might cause problems over time. One also has to

consider that the damage to T1 could be the result of multiple events of

a smaller magnitude over a relatively long time period that

accumulatively result in burned windings and a defective T1. Many other destructive scenarios can

certainly come to the imagination when the station antenna, when not in

use, is always left connected to the receiver input.

Of course, TMC expected that the ham

user would provide a T-R switching arrangement that protected the

antenna input circuitry in the GPR-90 since there isn't any antenna

input isolation provided in the receiver's design. TMC expected that the

ham installation would not only disconnect the receiver antenna input

but also ground the receiver antenna input upon transmit. The later

style DowKey coaxial relays provided a spring-loaded disconnect inside

the receiver-side SO-239 barrel to provide additional receiver isolation

upon transmit. But, for other types of energy sources, DowKey relays (and most other types of coaxial

antenna relays) didn't provide any isolation when the relay wasn't

energized, that is, in the receive mode. This "receive mode" was the

normal "power off" position for the typical ham station and it provided

a direct path for some types of antennas through the GPR-90's T1 to

chassis ground. Most hams knew that entirely disconnecting the equipment from the antenna and then grounding

the antenna (when the station wasn't

being used) was the best insurance against lightning damage.

However, from the quantity of damaged receiver antenna input circuits

found today, this type of protection seems to have been generally

ignored by many amateurs in the past.

What is unfortunate is that when T1 is "fried," the

receiver might still seem to function okay. An

inexperienced seller might even list the receiver as working fine. The

problems experienced with a defective T1 are subtle in some modes of

reception,...the AM mode with AVC on, RF at maximum, for instance.

However, in the CW or SSB mode, a defective T1 becomes very apparent. In checking out a

prospective GPR-90 purchase, if possible, measure the isolation between

the primary and secondary windings of T1 and measure the winding's DCR

to verify that it will function correctly. However, many times you won't

have the opportunity to measure T1's DCR because it won't even be there but will be entirely missing. Luckily,

T1 wasn't used in the GPR-90RXD versions of the receiver. However, I do

have to mention that even my RXD had Band 3 RF transformer's primary winding

"burned open" so putting destructive energy into a receiver's antenna input

does seem to happen a lot more often than one would think. One has to

keep in mind that these receivers are 65+ years old and a lot could have

happened to them in that length of time.

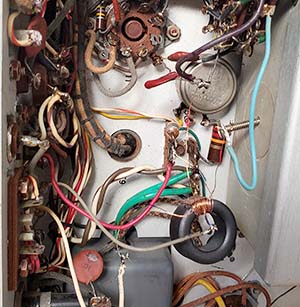

11. Extensive Use by Commercial Users

and Reworked by Hamsters - This isn't specifically

mentioned on the Internet but it is implied by some of the reviews. How

a receiver was used and maintained in the past can result in a litany of

problems after 60+ years of existence on the Planet. Many GPR-90 Series

receivers have extensive wear, especially those receivers used

commercially or by the military. Many of these types of receivers were maintained by

commercially employed technicians that had no regard for the equipment they were

employed to maintain. Many receivers were virtually destroyed by commercial

technicians with various types of rush-job, hacked repairs or non-engineered mods

that were for specific needs at the time by the end-user. Many of the

shields and top covers along the screws that mounted them were removed and

discarded. Many of the receivers, after surviving the gauntlet of

commercial technician maintenance, went on to ham ownership. That

sometimes ended up with the receiver being worked on by avid readers of

CQ magazine (nowadays, Electric Radio magazine) who were ready to

install the latest unvetted modifications published in the magazine

thinking that the mod will "solve all problems." Many of the hamsters

lacked any electro-mechanical ability but always seemed eager to modify the receiver rather than

actually repair it correctly. Also, hamsters always seemed eager to drill and

"hack-in" a non-original receptacle rather than

simply change the plug on the cable or accessory they wanted to use. So,

expect to find non-functional modifications, or maybe RCA phono jacks for antenna connections, speaker connections and

other circuit access points or Cinch-Jones receptacles installed just to

make it difficult to "de-mod" the receiver. The upshot is not too many of the

commercial GPR-90 receivers

have survived in operational condition, let alone in original, pristine

cosmetic condition. Some will be found that

have been competently rebuilt, look great and function to specifications,...but many others will be

non-functional, worn-out "hack jobs." To a certain extent, this

has led to impetuous judgments being made on receivers that haven't been

serviced in decades and certainly have corrupted circuits,

worn-out or broken components, possible wiring errors from mod installations and environmental contamination ingression from poor storage

conditions. The GPR-90, that is, not the RX, RXD or other

commercial-military models, being that it was a ham receiver, might have faired much better overall.

This would mainly be because the ham receivers

weren't subjected to the

rigors of commercial-military use or those types of maintenance programs. Naturally, it depended on the

ham owner,...and, after

nearly 70 years, there have probably been a lot of those. But, typically

the GPR-90 will be found in better physical/cosmetic condition than any of the

commercial-military variants. A ham-owned GPR-90's "electronic condition"

though is another matter.

12. Power Transformer Failures

- This wasn't one of the Internet complaints but something I've noticed

in examining many GPR-90 receivers. Most of the replacement power

transformers were installed in commercial or military versions of the

the GPR-90. That would be the GPR-90RX and RXD primarily, but I've also

seen a replacement power transformer installed in a GRP-90R receiver.

The conclusion drawn would be that since the standard GPR-90 receiver

was a ham receiver it wasn't normally operated 24/7 and, therefore, if

there was a component failure, it was immediately noticed and the power

shut off so the power transformer never had a chance to over-heat and

fail.

However, the commercial-military receivers were operated long hours,

perhaps 24/7. They were commonly left unattended for long time periods while still powered up.

This appears to have taken a toll on the power transformers due probably

to the transformer over-heating possibly from a component failure that

wasn't noticed for several hours. So, inspect any "prospective-purchase" RX, RXD, R

and any other GPR-90 version that was intended for commercial-military

operation,...you'll probably discover that the power transformer has

already been

replaced (or it might still be defective.)

13. Manuals - Again,

Internet reviews don't mention the TMC manuals. The GPR-90 manual just

okay since not a lot of information is provided. The circuit

descriptions are very basic. The installation and operational guide are fine with lots of drawings. Voltage and resistance

charts are provided. Alignment information is fine. The biggest problem

is that no under the chassis component identification or location is

provided, not even a photograph. TMC does provide a slight hint at a component's

location with a brief notation in the parts list in the column "Function

& Location." For example, looking at C11 the notation is "Cathode

Bypass" and "V2" for the location. I guess it's better than nothing at all. The GPR-90RXD manual

is much more detailed, probably because the receiver was

commercial-military in its expected use. There are several enlarged

schematics that show just certain sections of the circuit that are used

along with a better, more detailed circuit descriptions overall. Still, although there

are photographs of the top and bottom of the chassis, none of the small

individual component locations are identified. Even the "Function &

Location" in the Parts List is reduced to just "Function." You're on

your own to trace out the wiring versus the schematic to locate any of

the individual small components. Interestingly, the

CV-591A/MCR-4 manual has the components that are mounted on the numerous terminal boards

identified. However, individual small components under the chassis

aren't identified in this manual either. Although all of the TMC manuals are pretty good,

don't expect totally complete information,...but that's typically the way most

equipment manuals are anyway.

14. Conclusions - I've

used the GPR-90 and the GPR-90RXD on-the-air several times over the

years. Although

this is on-the-air operating on 75M where almost any receiver has the capability of

providing decent reception. The challenge on 75M is to provide enough selectivity to have the ability to copy weak signals through the noise and QRM. I've found that

the Crystal Filter is a major factor in being able to use the GPR-90s as

a ham receiver. The audio is very nice for AM and the receiver's ease at

being able to set up the remote standby is a big help. So, the GPR-90s can

be used successfully in a vintage ham station provided you operate

mainly on 75M in the AM mode. I'm sure 40M wouldn't be a problem either. 20M through

10M signals seem just fine but I've never operated a GPR-90

on-the-air on those bands,...just in the listening mode,...and in that

mode the receivers do fine up into

the 10M band. BUT, "doing fine" is a judgment based on

comparison to other 1950s vintage receivers, not to modern transceivers or SDR receivers.

|

Finally,...Things to Keep In Mind When Operating

a GPR-90

A. - Is the GPR-90RXD really incapable of receiving SSB? Do you have to "ride the RF

Gain" for both CW and SSB when using the GPR-90? Yes,...to

both questions. The standard GPR-90 and the GPR-90RX

will demodulate SSB quite well as a "stand alone" receiver but, with the GPR-90RXD, demodulating SSB

is almost impossible,...unless you have one of the TMC

CV-591A/MSR-4, MSR-6 or other 455kc input SSB adapters. These SSB Adapters make ALL the DIFFERENCE in

being able to successfully listen to all types of SSB or CW signals with

the RXD. The

GSB-1 will provide a very low distortion SSB signal from the GPR-90

since it has a product detector but the GSB-1 isn't an essential accessory since the GPR-90 (and the GPR-90RX)

have sufficient BFO injection levels to allow demodulating SSB signals

by a slight reduction of the RF Gain level.

B. - Do you need to use a matched or resonant antenna for best performance?

Yes, especially with the GPR-90 because of its

ferrite core Z-matching input transformer. An untuned end-fed wire will

generally not provide either 75Z or 300Z at the antenna feed-point. For best performance, an

antenna matching device (antenna tuner) should be used to assure

that 75Z (or close to it) is what the receiver "sees" as the

antenna impedance. All communications receivers will

function best with a resonant (or Z-matched) antenna and an antenna with some gain is even

better, especially a yagi or a quad on the higher frequency bands.

C. - Does the GPR-90 f-Drift a lot?

Not really. The GPR-90

isn't the worst receiver for frequency drift but there

was a reason why the military wanted the RX and RXD versions

with the capability of a selectable Crystal Oscillator for the HFO. The

Crystal Oscillator

allowed f-stable reception for RTTY operation where f-drift can't be

tolerated. Like almost all vacuum tube receivers, the GPR-90 will drift rapidly for the first 10 minutes

or so as it

warms up but then it settles down

quite a bit after that. Drift isn't noticeable on AM operation. On CW or

SSB, f-drift is noticeable because those modes require the BFO for

demodulation and that adds

to the f-variability making drift more apparent. Also, the CW and SSB

modes are both extremely easy for the receiver operator to recognize

f-drift,...CW by the heterodyne tone change and SSB by the change in

voice characteristics. For the vintage ham

station operator, the GPR-90 is actually about as stable as would be

expected for an upper-end priced communications receiver. Something

that can't be said for the HQ-180, unless you leave it plugged

in all the time so the HFO and BFO tube filaments always stay powered on

continuously, even when the receiver is turned off.

|

TMC's two-page advertisement in the 1956

ARRL Radio

Amateur's Handbook

No prices shown, you had to request the specific

bulletin for that information. Note that the loudspeaker shown

with the GPR-90 is the GPS-2 version (same cabinet depth as the

receiver.) And another thing,...wasn't A2 (MCW) illegal on the

HF ham bands? |

|