|

Antennas - My first serious listening session was using my 80M Inverted Vee

antenna with the feed line shorted. I logged two newly-heard NDB

stations. Not that they were any great DX, being

PND 356kc in Portland,

OR and BF 362kc in Seattle, WA, but they were new ones (#259 and #260,

respectively.) I quickly switched to a homemade remotely

tuned loop that was six

foot diagonally. In Nov 2019, I

went to a shielded magnetic loop, the Pixel

Loop. The impedance of the Pixel Loop is 75Z which is a good match for

the SP-600-VLF's 72Z input impedance. The Pixel Loop was a significant

improvement in signal to noise ratio and with ease of operation (the

remotely tuned loop had to be "tuned" every few kilocycles,...often, in

other words.) As mentioned, weak signal reception on MW is very much

improved using a loop antenna. However, on LF and VLF, when using a long end-fed wire antenna, sometimes it's

advantageous to have an inline switchable attenuator between the antenna

and the receiver. This allows reducing intense signals (not that common)

but it also allows finding the best response between the large antenna

and the noise generated by everything that the large antenna responds

to. I use a switchable attenuator that can reduce the signal levels down to

-82db in -1db increments. I've

found that around -20db seems to greatly reduce the noise while the

signals are still heard. Of course, the shielded magnetic loop is much

better at reducing noise but below about 100kc the loops don't respond

very well and a long wire is needed. The switchable attenuator will help in that

kind of setup.

The following

are some of the signals that can be received below 500kc,...

LW-BC - At one time

the LW-BC band was from 190kc up to 280kc. It was primarily used in

Europe and in Asia but many of the stations ran such high power levels

to large antenna systems that their signals could be received here in

the USA. As technology advanced, it became obvious to radio engineers that the low RF frequency

versus the AM modulation somewhat limited the resulting audio bandwidth that

could be produced by LW-BC stations. The argument was that better

fidelity was available from other broadcasting sources (many of the

avid LW-BC listeners didn't care about fidelity and these devoted

listeners kept LW-BC going much longer than expected.) Another factor was the enormous

cost to operate these stations and the value of the real estate that the

antenna system needed. LW-BC has been on the decline for decades and, as

of 2024, it has all but disappeared from the LW spectrum (BBC-4 is

one of the few LW stations still on the air but they claim

unavailability of replacement parts will one day force them off the air.) Of the LW-BC

stations that could be heard in

the Western USA only Radio Rossii 279kc, located on Sakhalin Island and

running 1000KW, was an easy station to receive

(although one had to get up very early in the morning for a good

signal,...5AM was pretty good because Radio Rossii shutdown at 6AM

Pacific Time which was midnight on Sakhalin Island. Programming was

Russian Jazz music and news - in Russian.)

All other LW-BC stations were extremely weak so the tuning was done with the BFO

on and tuned to zero beat. This is called an "exalted carrier" type of

reception of AM and it sometimes helps with weak signals. Unfortunately,

all I could ever hear on the European LW-BC stations was the carrier and the modulation wasn't

detectable. NOTE: About Russian LW Stations

- Radio Rossii 279kc and all other Russian LW BC stations were

shutdown Jan. 9, 2014. As an update for 2024, there are no LW-BC

stations transmitting that I can receive here in the Western USA. In

fact, there are only a few LW-BC stations that are actually "on the air" with most LW-BC stations being listed as "temporarily not operating" or "on standby" or

other vague notations that actually indicate the station is "off the

air." Economics, cost of maintenance, lack of high-power tubes,

expense of new replacement equipment that doesn't exist and that other reception options

are available that can provide better fidelity are the usual reasons listed for the station

going "off the air."

NDBs - Although NDBs are MCW signals, all "NDB-chasers" use a BFO (tuned to

~ 400hz offset +/- from IF) to help locate the NDB carrier and then tune to zero beat

to copy the MCW (this method results in a nice sounding 400~ note

depending on the particular NDB station.) Best

results for NDBs has the AVC off, BFO on and riding the RF Gain control. Nearly all of the NDBs tuned in seem

to have two or three signals on each frequency (well, that was the

case years ago, nowadays it's a sparse NDB environment with the future of airport NDBs

being tenuous at best. Hundreds of NDBs have been and continue to be decommissioned each

year over the past decade and, since no pilots in the USA use NDBs for

navigation, there's little incentive for airports to keep their NDBs in

operation.) Most NDBs are transmitting from 200kc up to about

440kc. There are a handful that operate from 510kc to 521kc. The power

output of a typical NDB transmitter is about 25 watts although many run

up to 100 watts and there are a few regional NDBs that run a few hundred watts.

There are a few transoceanic NDBs that can run up to 2KW. Antennas

are usually simple wires that aren't very high since they are normally

right next to the airport runway. A few regional and transoceanic NDBs operate vertical antennas.

DDP 391kc is one of the last operating transoceanic NDBs. It's located

in San Juan, Puerto Rico and is

running 2KW to a very tall vertical antenna. DDP 391kc is very easy to

pick up here in the Western USA during winter-nights - about 3500 miles

DX.

630M Amateur Operation

- This ham band is 472kc to 479kc. Any mode can be used. CW ops were

supposed to use 472kc to 474kc and then data mode users had the top 5kc

- all a "gentleman's agreement" that usually doesn't really function

very well,...much to the detriment of CW operations. Maximum power

output is 5 watts EIRP which doesn't sound like much but since the

efficiency of most ham antennas at 630M is so poor, actual power to the

antenna might be hundreds of watts to achieve the 5 watts EIRP. The are

several 630M ham beacons in operation. More information in the 630M

section further down this article. There also is a 2200M (136kc) ham

band, any mode, 1 watt EIRP.

Master Station "M" Fallon, Nevada -

Loran-E - The new and improved Loran-E has started up in

July 2024. Master Station "M" is using the same 625' tall vertical with

the 900' diameter capacity hat. They are using the same 400KW Megapulse

transmitter operating on 100kc and they are naturally transmitting from

the same location at the end of Loran Road in Fallon, Nevada. The old

Loran-C was shut down in 2008 (politics, mostly) but it was soon

discovered that there was an "over-reliance" on GPS navigation and the

very low power signals from GPS satellites could easily be interfered

with,...intentionally. As personal computers became more and more

powerful it became easier and less expensive for determined hackers to

disrupt and create errors in the GPS data. By 2015, official legislation was enacted to

restart Loran since its very powerful signals and very low frequency of

operation just about eliminated the possibility of external corrupting

signals trying to jam the navigation information. Loran-E works the same

way that Loran-C did in that the timing of the arrival intersection point of the wavefronts from three different

Loran stations define the location of the Loran receiver that's usually

onboard ship. There's now an extra pulse in the signal that carries

additional data to further help the navigators and users of Loran-E.

Also, users that have the old Loran-C receivers can still use those

receivers since they will still function with Loran-E. The additional

data won't be accessible but the navigational information will be.

Loran-C (and now Loran-E) was also used for other purposes by many other

operators around the world. The timing of the signal from each Loran

station was precise

and controlled by three cesium atomic clocks at the stations and many

operations based their timing needs on Loran's timing. All of that type of use

is still available with Loran-E. Master Station "M" is only 50

miles to the east of Dayton Valley so the signal on 100kc here is

formidable and intensely strong,...a good test signal on 100kc,...I can

easily pick it up on a crystal set. Listen

for "tick, tick, tick,..." that is constant and never changes

and never stops,...just a constant "tick, tick, tick." Each "tick" contains nine

pulses that identify if the station is a "slave station." The "master

station" sends ten pulses to identify it as the "master." All Loran

stations are on the same frequency of 100kc and precise timing is

imperative for proper identification of the "master station" and the

three "slave stations." Station "M" is the Pacific Master

Station with (if it hasn't changed) one slave station "G" in George,

Washington. Another slave station "X" is in Middleton, California and

the last slave station is "Y" in Searchlight, Nevada.

NOTE: For those who remember

how the old Loran-C signal sounded, Loran-E is a much faster "tick,

tick, tick."

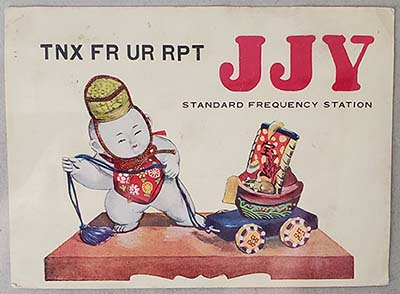

| LF Time Stations - In

the USA, WWVB is the best-known

LF Time Signal station, located in Ft. Collins, Colorado and

transmitting on 60kc. WWVB

transmits a 50KW pulse-encoded and simultaneously a phase-modulated time

signal that provides time-setting capabilities for compatible clocks. The

next easiest LF Time Station to pick-up is

JJY, located at Mt. Otakadayo, Japan, transmitting a

pulse-encoded time signal on 40kc. JJY

also transmits on 60kc. Like, WWVB,

JJY also transmits

phase-modulated information simultaneously.

JJY is the only LF Time Station that identifies itself in

CW which is sent at 15 minutes and 45 minutes after each hour (the CW ID

is sent twice each time.) Besides WWVB and

JJY, there are

several other "time signal" (both pulse-encoded and phase

modulated signals) stations located around the world. The most powerful

is ALS162/TDF in France running 800KW on 162kc.

ALS162/TDF is a former LW-BC

station that ran 1400KW (Yes! 1.4 megawatts.) When the LW-BC service stopped the station and

transmitter were converted to a phase modulated-type of time signal station (provides

clock time setting like WWVB.) The power was reduced to help conserve

the equipment and have a more economical operation.

ALS162/TDF is easy to receive

due to its tremendous power output but the time setting information is a phase modulated time signal

only. Phase modulated time signals sound

similar to a MSK signal. Phase modulation is used because much more

information can be encoded into the phase modulated signal compared to the

older pulse-encoded signal. There are also phase modulated time signal stations in

Germany DFC77 running 50KW on

77.5kc, UK MSF running 17KW on

60kc and Russia RBU running 10KW on

66.6kc. China BPC is running at

90KW on 68.5kc providing both pulse-encoded and phase modulated signals. Unfortunately, the UK station

MSF is on 60kc

like WWVB and the Russian station

RBU only runs 10KW, so picking

up these two stations is next to impossible here in the Western USA.

I've received all of the other time signal stations. The data

transmitted by these stations is for automatic self-setting clocks

and other such time-based devices so listening to these signals doesn't

provide much in the way of aural enjoyment. But since their frequency is

known and their location is known they do provide valuable test signals

for receiver-antenna performance and reception conditions. |

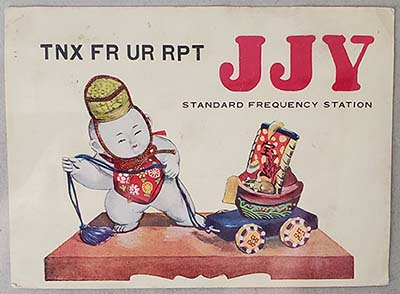

QSL card from JJY |

VLF Stations

USN Submarine Fleet Communications

- Stations

NAA,

NWC, NPM, NML and NLK are very strong MSK

(Minimum Shift Keying) Navy VLF stations in the 19kc to

25kc region of the spectrum. NAA 24.0kc

can run up to 2000KW while NLK 24.8kc

can run up to 1200KW. Both of these stations employ enormous array antennas to

go along with their tremendous power output.

NAA uses two trideco array antennas that are each

comprised of six panel "star shaped" umbrella arrays suspended by 26

towers that range from 1000ft to 600ft in height. Suspended just above the ground below the arrays are

the counterpoises that are the same size as the tridecos. The enormous

size of the NAA antenna system takes up an entire peninsula between two bays in

Cutler, Maine. NLK uses a dual

horizontal "W" array that is suspended from twelve, 200ft tall

towers that are placed up the sides of two mountains (Blue

Mt. and Wheeler Mt.) near

Oso, Washington. The dual horizontal "W" array spans across the valley

between the two mountains with ten vertical 900ft long drops that are

routed to twenty more towers on the valley floor that support the feed

line buss on one end and the ten feed line counter-weights on the other

end. The feed line buss routes the signal from the station house to the

antenna arrays. Each of the ten

antenna runs across the valley are between 8700ft to 5650ft in length

(each antenna leg span across the valley is over one mile in length!)

The entire valley has an enormous buried radial ground system that was

installed when the station was built in 1953. NPM

21.4kc

in Lualualai, Hawaii

and NML 25.2kc in La Moure, North Dakota each run 550KW to

a ground-isolated, 600ft tall vertical. Both verticals use large wire

capacity hats with isolators. NWC

19.8kc

runs 550KW to a single trideco array operating out of Exmouth, Australia. JJI

22.2kc is another MSK Sub-Comm station

that operates out of Obino, Japan (sometimes identified only

as "J.") MSK reception will require

that the receiver's BFO to be turned on. No information can be decoded

from these stations since the transmissions are multi-layered and

encoded so special equipment is required to reassemble the data and then the messages are encrypted, so "reading" anything is

impossible. The USN Sub-comm stations are useful

to LW enthusiasts in that their exact transmitting frequency is known along with

their location so they provide excellent strong test signals for the VLF region

of the spectrum. I've also heard regular FSK RTTY signals around 21kc

several times. Origin unknown. Other MSK signals will be heard from 19kc

up to around 50kc. Again, unknown origin. All of the USN Sub-comm

stations produce incredibly strong signals. Here in the Western USA,

NLK and

NPM are strongest. Then

NAA,

NML and finally,

NCW (but, even

NWC is usually a pretty strong

signal.) All of these stations are good test signals for VLF

reception,...day or night.

Russian VLF Navigation Signals -

ALPHA - RSDN-20

- The so-called "Alpha" navigation system transmits from three

major sites in Russia along with two other sites that are sometimes

used. The system uses many different frequencies that are all around

12kc, 14kc and up to 15.6kc. The signal consists of six 400ms duration

frequencies with a 200ms duration spacing. The signal duration is usually 3.6 seconds. Other times,

different combinations of coding are used, it seems to depend on maintenance and

other problems at the various stations. The primary Alpha

station is located at Novosibirsk. Secondary stations are at Krashodar and Komosomlsk-na-Amur.

All stations are in central Russia. There are two other locations

that are sometimes used at Revda (near Mirmansk) and Seyda. Power output is

500KW but details on the antennas used seems to be secret. What can be received usually

consists of "beeping" of the transmitted coded pulses that

if tuned correctly, two

different beep-frequencies will be heard,...sort of a "bee-boop"

sound. It was all typical "top secret" so not much is known about how the

system works, although it's thought that the Alpha system can be

used for aircraft navigation, maritime navigation and submarine

navigation. Since these are high-power stations in the VLF part

of the EM spectrum, they can be received day or night, if they

are actually transmitting. There are constant rumors that the

entire system is going to be shutdown but it still seems to be

running. Last reception here was 12/24/2024 during both daytime and

at night. The signal was only a single "beep" with about a five

second pause and then another "beep." No "bee-boop" like the

running or operational Alpha signals. Perhaps the system was

down for maintenance. If one station goes down, the entire system

doesn't work, so maintenance is a constant problem. The 12/24/24 "beeps" were on 12kc, 14kc and 16kc

approximately. From my reception location in the Western USA, the

"Alpha" signals are moderately strong and are about the same

strength as the USN-MSK station NWC 19.8kc located in Exmouth on

the coast of Western Australia (NWC runs 550KW to a Trideco

Array antenna.) There is some information on the

Internet,...search "Russian Alpha Navigation Signals" for more

details. Since the RSDN-20 signals are VLF and can be

received day or night, they are good lower-level test signals.

SAQ Grimeton, Sweden 17.2kc

- SAQ is the only operational Alexanderson Alternator, a mechanical

transmitter, in the world. When it

was new, it could run up to 200KW on 17.2kc in the CW mode but, due to the

transmitter's age, it now can run about 160KW but for conservation

purposes it normally is run at 85KW. The SAQ antenna is

enormous and consists of eight horizontal wires supported by six 425ft

tall towers. There are six vertical drops that connect to loading coils

to match the antenna load to the transmitter. These loading coils were

rebuilt a few years ago and now the antenna is running at about 10% efficiency so the actual radiated

power is 8.5KW (but actually it's probably even less than that due to

other losses in the system and the environment.) When the antenna

was new, the efficiency was rated at 14%.

SAQ is "on

the air" at least two times during a year. Christmas Eve and Ernst Alexanderson's

Birthday (in June.) Although the recent antenna loading coil work may

have improved the signal with better matching and loading capabilities,

still the signal reception in the Western USA, using vintage longwave radio

receiving equipment and human ears listening, is virtually

impossible. Most USA reception reports are using modern SDR (Software

Defined Receiver) receivers or other types of receiving equipment

with computer driven visual panadapter

spectrum displays and

computer recording capabilities (allows repeated playbacks for

analysis) rather than actual human listening in "real-time" to an

operating vacuum tube longwave receiver connected to a large wire array

antenna. Compounding the difficulty of "real-time" reception is that the

transmission from SAQ is at 9AM Christmas Eve morning over in Sweden,...that's

0000hrs midnight on the West Coast of the USA (nine hours earlier

- the ability to do a "timed" recording of the transmission would a

definite advantage in many ways.) I've never "clearly" received SAQ

in the many listening sessions I've tried. I've heard a few CW letters but nothing that

could definitely be identified as coming from SAQ (extremely weak, in

the noise and maybe in my imagination.) Yet other VLF signals within

a few kilocycles above and below 17.2kc are clearly received with

relatively strong signals. This shows that the capability of world-wide

VLF reception using "real-time" listening on vintage vacuum tube

receiving equipment connected to a large wire array is a reliable

possibility but it depends on the transmitting station's antenna system

and the transmitter's power output.

SAQ UPDATE: Dec 23-24,

2024: I tried listening for SAQ last night at 0000hrs. I

haven't tried this since the SAQ antenna work was performed, so I

thought maybe my chances might be better this Christmas Eve Day at

midnight. However, the report is exactly the same. Nothing definite,

some CW letters (maybe) but no words or call letters. SAQ sends a series

of "V" characters and multiple "SAQ" IDs before the

actual message transmission begins and

this wasn't heard. At only 8.5KW radiated power, from Sweden, on 17.2kc,

"real-time" reception seems unlikely (but I gave it a try anyway.) I did hear quite

well (and fairly loudly) the Russian RSDN-20 nav-signals on 16kc (also on

14kc and 12kc - running 500KW.) Also, NWC USN MSK Sub-comms station on 19.8kc from

Exmouth, Australia was very strong (NWC was so strong I had to use

the receiver's crystal filter to null out NWC's "bleed-over.") NWC runs 550KW to a single trideco

"umbrella array" antenna system,...and that illustrates the SAQ problem,...not enough power and

an inefficient antenna system. SAQ and its antenna system were originally

designed in 1924 for reliable communications with Great Britain and the USA

Northern East Coast, not world-wide

communications,...not then and certainly not a century later.

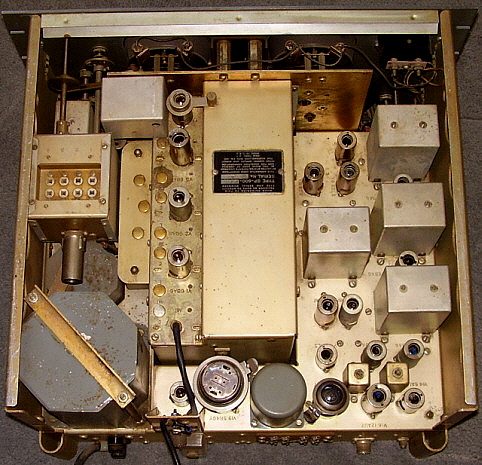

|

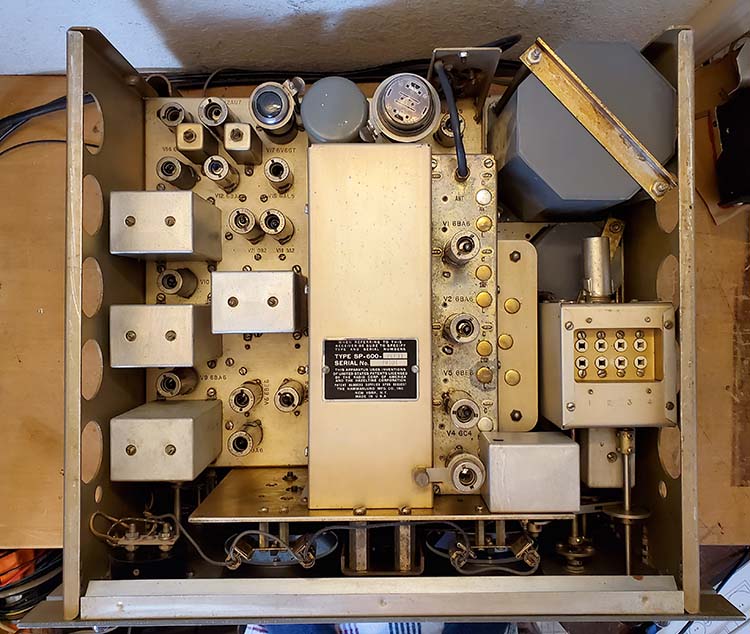

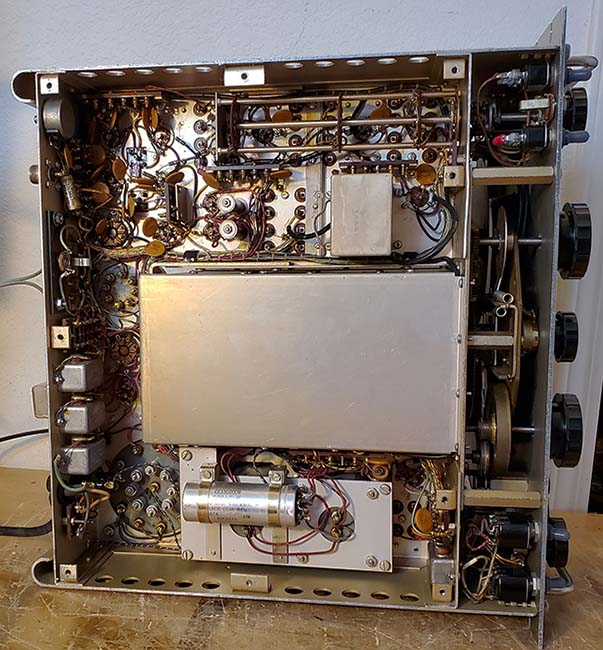

The carrier level meter is unique

to the SP-600-VLF |

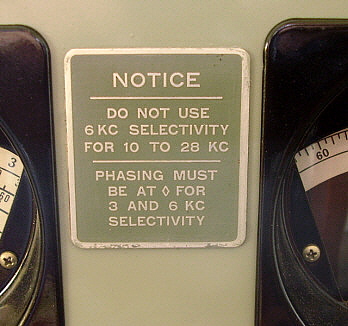

Only four crystal positions are

offered in the X option |

Tag between the tuning and logging

dials |

|

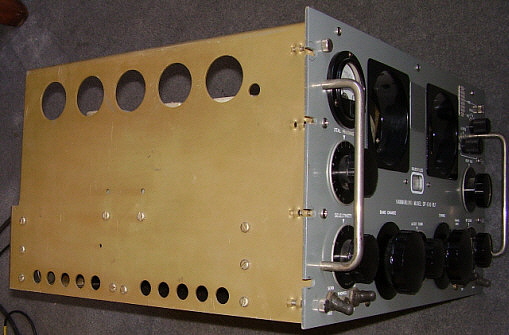

No receiver is perfect, so here are a few

"negatives" about the SP-600-VLF31 |

|

The SP-600-VLF31 Manual - Absolutely One of the Worst |

If

you're expecting the SP-600-VLF manual to be as detailed and comprehensive as the

manuals Hammarlund produced for the HF

versions of the SP-600JX you'll definitely be disappointed. As mentioned

in this write-up's introductory sentence, the first "questionable writer qualification"

happens right off when it's stated that the SP-600-VLF tunes down to an

"audio frequency of 10kc." Well, it doesn't stop there but only gets

worse. The first significant problem is that there aren't any

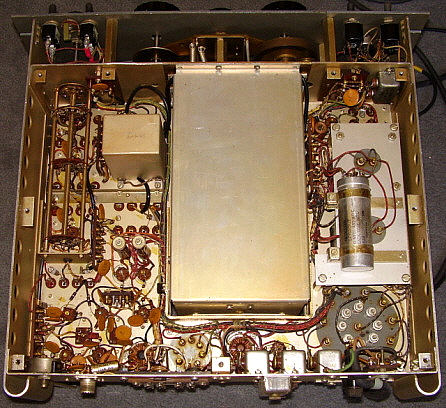

under-the-chassis component location drawings at all. There's a basic "top view" of the

chassis drawing that shows tube locations and transformer identification

but nothing to locate smaller individual components under the chassis.

There are photographs of under the chassis but nothing is

identified so these are no help for troubleshooting. If a specific component

location is required it becomes necessary to use the schematic and tracing the

wiring (sometimes using an ohm meter) to find the specific component location.

There are several component boards used under the chassis and there

aren't any drawings or photos to show or identify the components that are on any of

these boards - you just have to trace the wiring yourself to find out. All of the HF SP-600JX manuals

contained detailed wiring diagrams that illustrated exactly how the

receiver was wired, showing wire routing and connections plus showing

all of the component locations and how they were connected into the

circuitry. Usually there

were at least two wiring diagrams because so much detail was shown it couldn't

all fit on just one drawing (Hammarlund had to provide these drawings

since they were selling so many HF SP-600s to the military.) Not so with the "VLF" manual since there isn't a

wiring diagram at all - nothing! If

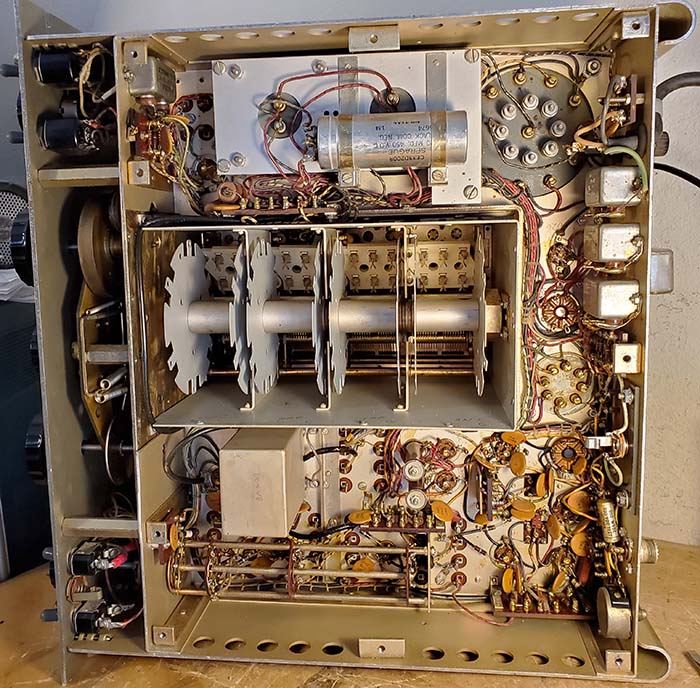

you take out the RF coils (and don't pay attention) there isn't any

information in the manual on how to correctly reinstall them. On and on,...only the

bare minimum of information is supplied. As far as written circuit

descriptions, they're detailed and very usable. At least Hammarlund

provided a tube pin voltage/resistance chart and the disassembly

instructions are good. Perhaps there was a

separate "Maintenance

Manual" for the SP-600-VLF that provided all of the expected (but

absent) information,...but I've never seen or heard of one.

By Far, the Worst Alignment Procedure

Ever Written - However, the "all-important" alignment procedure is

absolutely awful,...positively one of the worst and most unusable set of

instructions I've ever encountered. The alignment procedure reads as if somewhere in the Hammarlund

organization it was stated by one of the "higher-ups" that the "600-VLF"

alignment had to be "the most accurate alignment possible." So, the writing

task was assigned to an engineer that had never performed an actual

receiver alignment and,...since "best accuracy" was the goal,...that

had to achieved regardless of the practicality of implementation or the

time necessary for performing such an alignment or the amount of

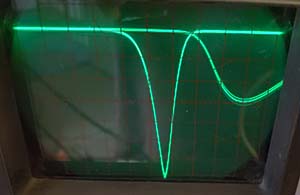

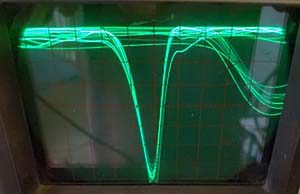

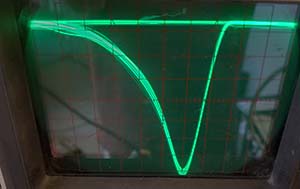

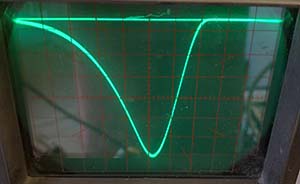

collateral damage brought about by the alignment. While sweep aligning the IF

is definitely the best method to achieve symmetrical passbands, you

shouldn't have to go out and BUY

special equipment to perform the job (the manual actually gives the

name of the company and their address where you could purchase the

specified special equipment - incredible!) And, you shouldn't have

to unsolder components in the receiver circuitry to accomplish the

alignment,...unbelievable.

Unsoldering

Components for an Alignment?

You Must be Kidding!

- The necessity of unsoldering the "loading resistors"

in the RF front-end is totally impractical. It requires removing each

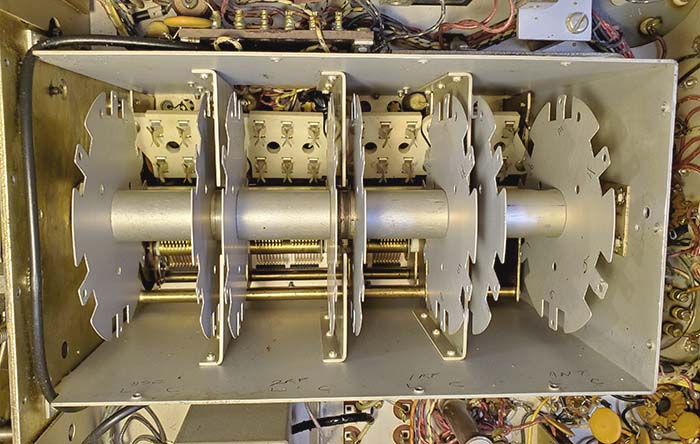

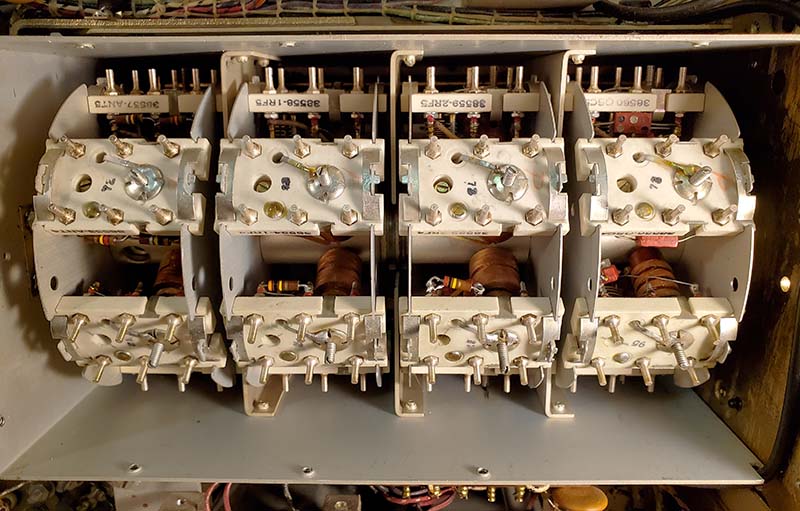

of the two RF coil assemblies (ANT and 1RF) from the turret on each of

the six bands first to unsolder the resistors. Then the coils are reinstalled in the turret and a RF

signal injected at the antenna input. Then a RF Probe-VTVM are used to

measure

maximum RMS voltage at the 1st and 2nd RF Amplifier tubes for alignment. Then the RF coil assemblies have to be removed

again, the load resistors resoldered and the RF coil assemblies reinstalled. That's

12 RF coil assemblies that are "in and out" of the turret four

times,...what an "exercise in potentially causing

receiver

non-functionality due to

component damage."

Simply unbelievable! In addition to the RF Probe-VTVM RMS measurement, the procedure

requires other special equipment that's not always available, e.g., a

sweep generator, the "special order" dual sweep trace oscilloscope (dual X vs Y inputs)

with a special detector probes to allow the ability to monitor both the

sweep input LC and the sweep output LC of the IF transformers

simultaneously while sweeping to allow finding coincidence,...on and on.

For every section of the receiver, the alignment procedure is overly

complicated requiring that certain components or wires be unsoldered from the circuit and then requiring

special equipment. There are so many components and/or wires that

are disconnected, rerouted, then the measurement/alignment performed and

then the component or wire reconnected it

would be a miracle if the components or wires could or would be returned to

their correct connections. The physical damage that's very likely

to happen with the action of unsoldering component leads and wires, then

reconnecting and soldering the parts back in place makes one cringe. The

amount of components that are tampered-with in the alignment procedure

is staggering beyond belief!

Why Publish a Useless Alignment

Procedure?

-

It's almost a certainty that any SP-600-VLF receiver would have been

initially owned by either commercial users, such as laboratories,

communications or monitoring businesses or possibly by the military. One

can confidently rule out any ownership of a SP-600-VLF by any amateurs.

Since ALL professional and military equipment would usually be aligned by

professional technicians, one would think

that the alignment procedure would have been written at "tech-level"

to allow each alignment to proceed along quickly and accurately. All of the HF

SP-600JX manuals, because those receivers were used extensively by the military, have easy to follow tech-level alignment procedures

with no special equipment required. Hammarlund should have

employed someone experienced in writing tech manuals to write this

section of the 600-VLF manual (or, to keep it simple,

just hire one of the Army Signal Corps TM manual writers.) So, why would

Hammarlund even publish this impractical alignment procedure? I'm sure

that if the SP-600-VLF had been sold in any quantity to the military, there

would have been an entirely different, Signal Corps military-style technical manual that

would have been available, similar to the HF SP-600JX TM11-851 manual. But, since civilian

purchasers from laboratories or commercial monitoring services, etc., were the

likely end-users, commercial technicians would be performing receiver

maintenance and that included alignments. But why would commercial techs

be expected to use this

"impossible to perform" procedure? In reading

the SP-600-VLF alignment procedure MANY TIMES, I've come to the

conclusion that Hammarlund didn't want anyone going into the

receiver to make adjustments and they wrote a procedure that

assured that NOBODY would even consider aligning the

SP-600-VLF per the manual. Perhaps Hammarlund wanted all SP-600-VLFs

returned to the factory for any type of repairs or maintenance and an

obtuse alignment procedure made sure of that. But, I'm sure that even Hammarlund

didn't align the SP-600-VLF as

described in the manual (so, what should you do? Read on,...)

Does the Alignment Procedure in the

Hammarlund SP-600-VLF Manual have to be Used? - In looking at the schematic of the

SP-600-VLF, it's obvious that it's a standard single conversion superheterodyne. There's

nothing special going on in the circuits. It can (and should) be aligned

just like any other superheterodyne. The bulk of the receiver circuit

operates at 705kc. Use 705kc for the IF. For the best results, sweep

align the IF. First, "peak align" at 705kc and then apply the sweep signal

at the grid input on each IF stage and do minor tweaks to the

appropriate IF transformer for the best shaped passband. Proceed from

the last IF to the Mixer always with the 'scope on the

detector output, the Diode Load (this is basically how a standard sweep IF alignment is performed,...more

details on sweep aligning the IF of the SP-600-VLF in the "2024 Workbench Visit" at towards the

end of this article.) The turret coil assemblies

function at various other lower frequencies than the IF. A RF signal

generator (or a very stable Function Generator) that can produce a RMS

voltage output down to 10kc is necessary. Adjust the

turret coils as if it were a HF SP-600JX but use the frequency table in

the manual (at least that part of the alignment procedure isn't corrupted.) Align the BFO and the Amplified AVC to

705kc. Adjust the 455kc IF conversion for maximum output at the IF

OUTPUT. Use a VTVM on the Diode Load and adjust for peak negative DC

voltage with the AVC off.

What is interesting is that my detailed

inspection under the chassis of the entire SP-600-VLF receiver and

detailed RF coil assembly inspection revealed that NONE of the

components or wires that were supposed to have one end unsoldered and

"lifted" had EVER had the original solder joint disturbed. That

indicates that whomever performed the maintenance on this SP-600-VLF

read the alignment procedure in the manual and knew it was unusable and

probably aligned the SP-600-VLF using conventional RF-IF alignment

techniques. And, this was probably the method used for several

alignments over the years. So, don't be afraid of the SP-600-VLF,...it's

a standard single conversion superhet that can be aligned like any other

similar type of receiver. Yes! I've aligned my SP-600-VLF, including a

sweep alignment of the IF, following conventional procedures and the

receiver functions great.

NOTE for HF SP-600 Owners: What a surprise!

The High Frequency SP-600 JX Instruction Book's Alignment Procedure really isn't a

lot better than the VLF's alignment procedure,...but at least you aren't

instructed to unsolder wire or components as part of the alignment. Although the peak IF

alignment is complete, if one wants to sweep align the IF, only two

sentences comprise the entire sweep procedure. In TM11-851, the same

special equipment is called out for the sweep alignment as is called out

in the VLF procedure (and the address is again provided.) But, TM11-851

does have the complete peak alignment instructions. At least the HF SP-600

Instruction Book's IF peak alignment procedure

is easy to follow and quick to perform. It's probably how almost all HF SP-600s

were aligned anyway. SO,...for those interested and who are owners of

any of the HF SP-600 receivers, I've added a complete IF sweep alignment

procedure for the HF SP-600 to the "Hammarlund SP-600

Receiver" write-up. No special equipment other

than a sweep generator and XvsY 'scope. Use Home-Index for navigation.

|

More

Issues,...but these are minor ones |

Dial Slippage - a Chronic Problem with all

SP-600 receivers (but

there's an easy solution) - All SP-600 receivers mechanically drive the tuning using the same set

up. A brass drive wheel is rotated with the Tuning knob. This wheel in

turn drives, by friction, a brass reduction wheel that is spring-loaded

against the drive wheel. The reduction wheel is grooved and mates with

the Logging dial driving it, by friction, at its perimeter. Driving the

Logging dial shaft tunes the receiver tuning condenser through the

gearbox. If

contaminates are allowed to accumulate on the friction drive surfaces

eventually dial slippage will be the result. Although some SP-600

enthusiasts believe that the "S" spring used for loading the reduction

wheel causes the slipping, I've seldom had just the spring be

responsible for dial slippage. Almost always, dirt and grease will have

collected on the friction surfaces of the brass wheels or on the rim of

the Logging dial and this is what is causing the slippage. Thorough

cleaning is necessary to correct the problem. Fortunately, all parts are

accessible without any disassembly. The brass wheels can be accessed

with the receiver on its side and the Logging dial rim can be accessed

from the top. Clean all friction surfaces with denatured alcohol. I use

several Q-tips to clean the brass wheel surfaces. Repeat the cleaning

until the Q-tips don't turn black. On the rim of the Logging dial, I use

a small piece of paper towel that is dampened with denatured alcohol.

Again, clean until the towels don't turn black. Remove and check the "S"

spring. It should be straight or slightly bent out. If it's bent inwards

then the spring load will be somewhat reduced. You can expand the "S"

spring by just bending it outwards with your fingers. Reinstall the "S"

spring. As an added help, check the rotation of the logging dial and how

much resistance to movement there is in the gearbox. Years of storage

with no use or no

maintenance may dried up any lubrication. It would certainly help to lubricate all of the shaft bearings with a drop

or two of

10W machine oil. As always, don't "over lubricate" and just apply

a drop or two of machine oil only where needed. Also, check that the Dial Lock is completely open and

not "dragging" on the Logging dial. Check the SP-600 tuning now. It

should not slip and should be "velvet smooth."

UPDATE: Jan. 1, 2018

- The slipping dial is back. Although I haven't pulled the receiver out

of the cabinet I can see what I think is the problem. The logging dial

rim has a small gouge that I think is causing the slippage since this

"dent or gouge" changes the dial friction in the drive wheel groove when

the gouge comes around. I also noticed that the logging dial has a

significant bend so it isn't really engaging into the drive wheel groove

with the same "fit" each revolution of the drive wheel. To repair this

will be a receiver out of the cabinet and front panel off since I'll

have to dismount the logging dial for straightening and repair of the

gouge. I'll do this after the Longwave season is over - probably around

March.

UPDATE: May 1, 2018

- A Solution That Works and isn't Difficult to Implement

- Slipping dial issue required pulling the receiver out of the cabinet

and then disassembling to the point where the front panel could be

removed. The dial lamp assembly over the logging dial has to be removed.

Then the three screw mounting plate is removed and the logging dial can

be removed. Close inspection revealed that near "45" on the dial rim

there was a deformation that had a "lumpy" feel to it. Also, between

"50" and "55" was another rough area. I carefully dressed these areas

with a very fine jeweler's file. The dial also had a warp that was easy to take out

with minor flexing of the dial. Upon reinstalling the dial on the hub, I

found that the slipping was still happening in the same areas. I

readjusted the "S" spring for a greater load against the drive wheel. No

improvement.

The Slipping Dial Solution - I thought about how improve the "grip" of the brass against

brass surfaces and came up with the idea of using rosin. I dissolved some powdered

rosin in some denatured alcohol to make a thin (viscosity like water)

mixture. I used a small paint brush to apply the rosin mixture into the

drive wheel groove. Then I rotated the logging dial to transfer some of

the rosin mix to the rim of the dial while applying more rosin to the

groove with the paint brush. I let the mix dry (alcohol

evaporates.) That did it. No more slipping - none at all! I didn't need much

rosin-mix, just a little brushed just into the drive wheel groove worked

great. If the rosin somehow disappears from the drive wheel groove in

the future, it's very easy to reapply the rosin-mix. Hopefully, the

"grip" will last for quite awhile. NOTE: The rosin-mix probably should be

reapplied each year for best results. For an update on the

rosin/alcohol mix read the update for Jan 6, 2021 further down this

page.

Jan 3, 2021 - Maintenance Required - I had been noticing that

changing the SELECTIVITY would cause signal loss and erratic reception. The problem turned out to

be in the SELECTIVITY switch that apparently I'd never cleaned. De-Oxit

and a small paint brush (and cleaning out a few spider webs) got the

switch operating fine. This seemed to clear up the problem. This is a

common problem with the HF SP-600 also. I've noted that for quite a while now

the dial is again slipping. Not nearly as bad as before but it's getting

worse. More rosin/alcohol mix needs to be applied to the drive wheel.

UPDATE: Jan 6, 2021

- More Rosin

- The rosin mix was still working fine in the small groove of the idler

wheel that actually drives the dial. The beveled drive wheel that

interfaces with the idler wheel was where the slipping was happening

since I hadn't ever applied the rosin mix there. I cleaned the bevel

with alcohol and several Q-tips turned black indicating dirt or

contamination of some type. Just cleaning the bevel gear helped with the

slipping but I applied new rosin/alcohol mix to ALL drive surfaces this

time. After the rosin mix dried, no slipping. Just as another

precaution, I adjusted the spread of the "S" spring for the dial drive.

This increases the engagement force of the idler wheel into the bevel of

the drive gear. The dial drive now seems excellent with no slipping.

We'll see how long this lasts - I think I can probably go about two

years between the "rosin" treatments - not bad,...it's an easy

fix. NOTE: I've actually gone three and half years and still no

slipping - 2024.

Shielded Magnetic Loops

- The SP-600-VLF does tend have a high noise floor that makes using

certain types of wire antennas in the MW and LF spectrum nearly impossible.

Best performance on MW with my SP-600-VLF has ALWAYS been with a loop

antenna. At first, I was using a homemade remotely tuned loop that

worked very well. I switched to a Pixel Loop in November 2019 and it

also works quite well. My Pixel Loop was purchased used and it's an old

one that was actually built by Sirius years ago. Nowadays, Pixel Loops

are still available but the disadvantage is not only the expense of a

Pixel Loop (about $800) but they always seem to be on "back order."

Pixel Loops are available from DX Engineering but expect to wait for

actual delivery. The other good LW loop was the Wellbrook Loop.

They came from the UK but now Wellbrook is out of business. Wellbrook Loops are

frequently seen for sale "used." The Wellbrook

Loops seemed to have problems with their LNA although, when they were

still in business, they would replace them if the failure was component or workmanship

related and they could be purchased separately, if needed. I've seen

replacement LNAs for sale by private owners on eBay. Chameleon also made a high quality shielded magnetic loop a few

years ago but it was mainly for HF and didn't perform as well as

expected on MW or LF (this opinion was expressed in an Internet

review of the Chameleon loop.) There are other

much less expensive loops that are made out of coax for the loop portion

using the coax braid for the shield and the center conductor for the

antenna. These type of shielded magnetic loops are from W6LVP and they

are mainly designed for HF, so MW and LF may not perform as well as expected

(again, this was an Internet opinion and my experiments show that the

signals start dropping off as the AM-BC band is tuned through.) Also, these coax loops aren't

particularly durable when used outside (also Internet opinion.)

As an indoor loop they might be an inexpensive alternative. The coax

loops are about half the price of a Pixel Loop at $345.

NOTE 2024: I've had the

Pixel Loop since 2019. I was just given a W6LVP loop in 2024. This gave

me the opportunity to test both loops "side by side." Throughout the HF

spectrum, that is from 3mc to 30mc, both loops' performance is nearly

identical.

Through the AM-BC band, the W6LVP loop begins to have minor losses but the Pixel

Loop remains at the same performance level. Below 500kc, the W6LVP loop

will pick up some stronger longwave signals but no MW DX, so the signal

loss is noticeable. The Pixel Loop maintains the same performance level down

to 100kc and I've even used it down to 24kc for the USN VLF stations, of course,

signal losses are noticeable but those USN stations produce very strong signals. I'd rate the W6LVP loop as very good for HF

but not so good below 500kc and, in fairness, it's spec'd as a loop

for 160M to 10M operation so expecting it to function well below 500kc

isn't how the antenna was designed, manufactured or advertised. The

Pixel Loop is spec'd from 30mc down to

150kc.

Homemade Remotely Tuned Loops

- These types of loops are not difficult to build and their performance

is usually a vast improvement over a wire antenna. Finding the MVAM-108 varactor

diodes (bias voltage changes the capacitance for remote tuning) might be

difficult nowadays. If the MVAM-108s can be found then building a

remotely tuned loop is easy and the bias voltage can be provided by a 9

volt battery and a high resistance 10K potentiometer with 1 meg isolation

R. A switch is necessary to isolate the battery when the loop isn't in

use.

Plans for a remotely tuned loop are in Part

4 of "Vintage Long Wave

Receivers." Use Home/Index at the end of this article for

navigation.

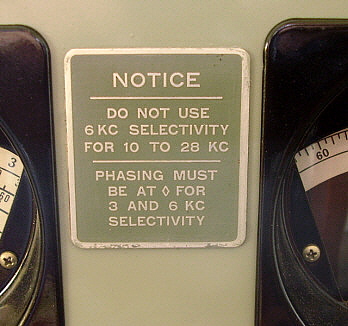

Dual Crystal Filters - The Selectivity options are limited because the Band Pass crystal filter and

the Phasing crystal filter that

are always in the circuit for every selectable bandwidth, even the 6kc

bandwidth. Nowadays, there are virtually no Voice-Music signals being

transmitted below 530kc. The only possibilities for music would be on

540kc AM-BC and for Voice on 530kc public service broadcasting. I haven't heard the TWEB NDB RWO

394kc from Alaska in a couple of years. TWEB NDBs transmit Voice weather

with MCW ID. RWO has probably been

decommissioned. LW-BC

is nowadays (2024) limited to just a couple of stations that

can't be received in the western USA. So, there really aren't any

Voice-Music stations transmitting that would benefit with a non-crystal

filter IF bandwidth position. The Crystal Filter operates differently

than a typical crystal filter in that the entire rotation from 10 down

to 0 on the PHASING dial scale varies the bandwidth from maximum (10) to

minimum (1.) There is also a very narrow peak that moves around the

passband as the PHASING control is rotated that can be used for peaking

a particular heterodyne tone in CW. The first Crystal Filter is

essentially non-adjustable and is actually a crystal-controlled Bandpass

Filter centered at 705kc.

Dial accuracy is

typical of non-Collins gear from the 1950s. The accuracy is very good

(after an alignment) but the dial resolution could be considered vague. With the inclusion of

the Logging Dial it's obvious that Hammarlund expected extreme accuracy to

be determined with a Heterodyne Frequency Meter and then the Logging

Dial used for accurate frequency reset. All typical of 1950s

designs, so this is not unexpected.

Hard to Access BFO Tube

- Accessing the BFO tube will require removing the shield-box over the

LO switch for the Crystal Oscillator. There's a hole at the back of the

shield-box that allows access to the mounting screw. Don't remove the

screw,...just loosen it. Then the shield-box can slide upwards (it's a

long slot that the screw works against) to clear the screw. With the switch shield-box

dismounted, now there's easy access to the BFO tube although a

long-handle tube puller might make removal of the tube a bit easier. When BFO

tube testing is completed and a good tube installed, then reinstall the

LO switch shield-box. When aligning the receiver front end, this

shield box has to be removed to allow access to the OSC L-C adjustments.

Hammarlund SP-600 Cabinet Rack

Mounting Screws, Straps and Holes - The eight holes for

the rack screws to mount the receiver into the cabinet don't have any

threads. In fact, they're just .250" diameter holes. Instead, a steel

strap with four 10-32 tapped holes is placed behind the cabinet holes with the

receiver in place in the cabinet. Reaching around the top side of the

receiver side panel, the steel strap can be moved around with the

fingers (sort of.) The tapped holes have to be aligned with the

cabinet holes and with the receiver rack notches. Then one of the 10-32 rack

screws can be hand-threaded into one of the strap holes. Once one screw

is threaded in then the strap won't fall and the other three screws can

be installed. This maneuvering of the steel strap to align with the

cabinet holes has to be repeated for the other side. Once all eight screws are

threaded in they can then be "snugged" - that is, not

over-tightened. These two steel straps really are time-consuming to deal

with and many times in trying to get the strap holes aligned with the

cabinet holes you'll end up dropping the strap and it will fall to the

bottom of the cabinet. That requires pulling the receiver out of the

cabinet to retrieve the strap, which is a real pain. Though I haven't

done it, I've thought about drilling two holes in the cabinet rack

mounting flange to accept 6-32 flat head screws. Then drill and tap the

strap (6-32) so that the mounting of the strap has the four rack 10-32

holes aligned with the cabinet .250" diameter holes. The flat head

screws wouldn't interfere with the receiver mounting and the straps

would always be aligned correctly and couldn't fall down inside the

cabinet. A good idea,...I just haven't done it yet. Just in case you

think that clip-nuts could be used, the dimensions are slightly

different. To use clip-nuts would require enlarging the cabinet's screw holes.

Once that's done, then the clip-nuts will work.

|