|

Howard Radio Company - 1926 to 1949

Howard Manufacturing

Company - 1922 to 1926

Electric Specialty Company - 1921

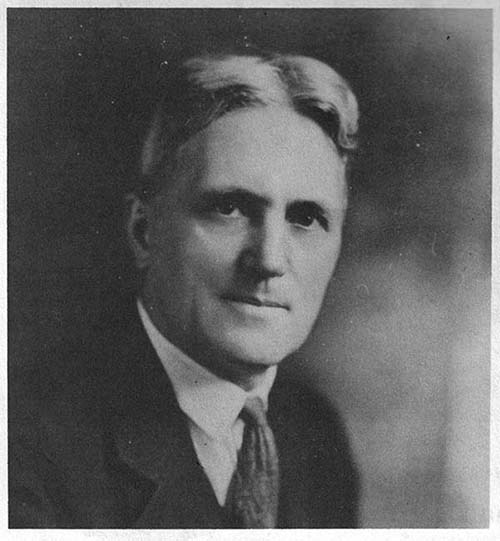

Austin A. Howard was born in 1872 and, by 1905, was already building

radio apparatus. He was a ham radio enthusiast

before WWI and, in 1918, the Navy performed transmission tests using his

station in Chicago. He had an experimental call, 9XG, up until 1922. He

was at the First National Radio Exposition in Chicago in 1921 where he

represented "Electric Specialty Company" which was probably

the forerunner to Howard Manufacturing Company. Howard Manufacturing

Company began building

and selling

radio equipment around 1922.

In 1924, Howard obtained a Neutrodyne

license from Hazeltine (he was the last company to obtain a Neutrodyne

license thus becoming the last company to be accepted into the

Independent Radio Manufacturers, a group of fourteen radio companies that were

the sole legal builders of Neutrodyne radios and the exclusive holders of the Hazeltine Neutrodyne license.) Howard

Manufacturing Company was located in Chicago, Illinois. Austin Howard

was already independently wealthy so Howard Radio Company was operated a

little differently than the other 1920s radio companies. Howard built

modest quantities of very high-quality radios at a fairly leisurely pace and

sold them for hefty prices. Just the opposite of another 1920s

independently wealthy radio builder, Arthur Atwater-Kent, who built

literally millions of radios and sold them for more or less average

prices.

|

Howard Mfg. Co. -

1925 Model C Neutrodyne

The Model C is typical of

the Howard radios produced in the 1920s. This was a very large

and very expensive five-tube Neutrodyne receiver

that sold for $180 during early 1925 (introduced in March 1925.)

photo: eBay |

Howard changed the company name

around 1926 to Howard Radio Company. Howard was

able to obtain a RCA TRF license in 1927 and then later the Superheterodyne

license. Howard had to build a tremendous quantity of radios per

month to be able to afford the minimum royalty to qualify for the RCA

licenses. Howard's low production rate had to change and, beginning in

1927, Howard's work force dramatically increased along with the company

offering several different

models of radios.

About this time (1929,) Howard Radio Company was purchased by the

Everett Piano Company and they moved manufacturing to

South Haven, Michigan. Everett Piano bought Howard just before the Stock

Market Crash and then tried to work their way into the radio business

during the depths

of the Depression. Everett Piano Company wasn't making any money building

radios so they sold Howard Radio Company back to Austin Howard in 1934.

McMurdo Silver, Silver-Marshall and

the RCA Licensing

- Howard moved the company back to Chicago in 1934 and ended up operating in McMurdo

Silver's building that had been Silver-Marshall. McMurdo and his cousin,

John Marshall, had started Silver-Marshall in the late-twenties. RCA

licensing became a necessity of being in the radio business after the

1930 "Radio Group" Anti-trust suit. The settlement of that suit put RCA

directly controlling almost every aspect of radio manufacturing. The Superheterodyne

circuit was part of the settlement. It had been Westinghouse's property

since 1920 but the government settlement gave the Superhet patent to RCA

with the stipulation that licensing had to be provided for qualified

manufacturers. Large radio companies that could produce huge quantities

of radio, such as Zenith, Atwater-Kent or Crosley, didn't have a problem

producing the large amount of radios required but smaller companies

couldn't directly qualify and that was Silver-Marshall's situation.

Becoming a subcontractor was one way around the RCA licensing and that

was how McMurdo Silver dealt with his lack of a RCA license. By inviting

Howard Radio to move into the Silver-Marshall building and manufacture

radios there, any other radio building for other smaller companies

involved would be covered by Howard's RCA licensing. It was a solution

that benefited not only McMurdo Silver but later Bill Halligan and

others, not to mention Howard Radio.

|

Sears-Roebuck Co. -

Silvertone 5656A - 1937

Sears had Howard

Radio Company build these eight-tube superheterodyne receivers

in 1937. Despite the low selling price of just $49.50, the 5656A

was a surprisingly good performer that offered a RF amplifier stage, variable-coupled IF amplifier

stage, IF gain control (Sensitivity,) a Standby switch,

headphone jack and a built-in 8" Jensen field-coil loudspeaker. |

Bill Halligan and Hallicrafters

- Ultimately, Howard found that it was much more profitable to build radios for

other companies as a contractor and his RCA and Hazeltine licenses allowed him to do

just that. Halligan was friends with McMurdo Silver and had been selling

his very early radios by mail-order since this could bypass the license

requirements. Halligan made arrangements to have his receivers built at

Silver-Marshall by Howard Radio. That allowed Hallicrafters to develop

their radio circuits and use RCA TRF and Superheterodyne circuits,

protected by Howard's RCA license. The Hallicrafters business

ended about August 1936 when Halligan made arrangements with Case and

bought the Echophone Company to acquire their RCA license and

manufacturing facilities.

|

Sears-Roebuck

and Howard Radio - Howard's biggest and most

profitable customer was the Sears-Roebuck Company. Of course,

Sears-Roebuck's "Howard-built" radios were labeled "Silvertone"

as all Sears' radios were. The Howard Radio Company

identification was usually only a manufacturer or contractor

number. Howard Radio almost always used the number #1731 as

their identification. This number was supposedly based on the

Silver building address of 1731 Belmont in Chicago. Typically, a

stick-on paper model label was applied to the radio chassis that

had the "Howard ID" on it. Sears had always been reluctant to

reveal that Silvertone radios were built by

contractors, although almost everyone knew that fact. In the

later thirties, Sears Silvertone radios have no

indication of the contractor-builder of their radios. In

the later half of the thirties, Howard began to build and sell

ham-communication shortwave radios. Some of the communication receivers

were built for Sears-Silvertone but Howard did sell their own brand of ham

receivers with a lineup that featured examples from entry-level

receivers up to advanced-level communication receivers.

Howard Radio Co.

Receiver Design and Build Quality - Howard's communication receivers were designed and

built to be affordable, therefore the chassis

design used what were essentially

broadcast-entertainment radio components. Some of the

small Howard ham receivers

were obvious AM-BC-SW radio conversions to entry-level,

metal cabinet, shortwave receivers that could have been

usable in the stations of neophyte hams.

The quality

level of

Howard communication receivers was similar to the receivers produced by Hallicrafters, Radio Manufacturing Engineers or Breting Radio Company. Howard's

receivers sold for about the same price as the Breting receivers

but were priced less than comparable Hallicrafters or RME receivers. Breting receivers in particular

were fairly crude in their wiring and their mechanical assembly

where as Howard receivers were more professional assemblies

but of an

average quality,

somewhat similar to Hallicrafters and RME. Wiring lead

dress in Howard chassis is mostly "point-to-point" with an

almost "messy" quality to it. Some self-tapping screws are used

along with some rivet-mounting. Copper-plated chassis were used

for many of the receiver models.

|

1938 Howard Model

450A Communication Receiver

This was

one of Howard's largest and most elaborate communication

receivers featuring 12 tubes and tuning from .54mc up to

60mc. Other features included dual IF frequencies, a

Crystal Filter, Dual Frequency BFOs, 9 watts of

Push-Pull Audio output and a spectacular tuning dial

system |

The component quality is comparable to Howard's competition

with quality capacitors and some well-known component manufacturers being

standard. Most of Howard's components and mechanical

parts came for manufacturers located around

Chicago. This local purchasing of components was also common with Hallicrafters,

Wells-Gardner, Zenith and other Chicago-based companies.

The engineering design of Howard receivers is similar to Hallicrafters

in that the design had to use purchased parts. The majority of

components had to be standard issue

that could also be used in AM-BC-SW consumer

entertainment radios

and preferably available from Chicago companies. Most of the

communication receiver manufacturers built their products in the

same manner. There were really only two communication receiver

builders at the time that built all of their own assemblies and

purchased only passive components. The two companies were well-known for that fact,...National Company, Inc. and Hammarlund Mfg. Co., Inc.

Howard never

seemed to put a lot of money or effort into advertising and that might be

why Howard communication receivers and his smaller SWL

receivers never really gained a foothold in hamdom.

Nowadays, you'll see Howard Radio communication receivers once in a while though not nearly as

often as Hallicrafters or RME receivers.

WWII and Post-WWII

- Howard's ham

gear line-up ended when WWII began and Howard Radio Company then built

for the war effort. Howard Radio's most famous WWII contribution was as an alternate

contractor for the production of BC-779 Hammarlund Super Pro receivers.

These BC-779 receivers will have a data plate on the front panel

indicating that the receiver was built (or assembled) by Howard Radio Company.

|

Howard-built version of the

Hammarlund BC-779-A Super Pro from ca: 1945

Note "Howard Radio Co." on the data plate

- photo from Ed -djed1 |

Howard Radio

really never came back after WWII ended. The company offered a few table model

consumer radios and a FM converter for a short time. Howard himself was in his mid-seventies by this time so

it's not surprising that the Howard Radio Company was

out of business by 1949. |

|

Profiling Six

Ham Receivers Built by Howard Radio Company

|

|

Sears-Roebuck - "Silvertone"

Model 5656A - built by

Howard Radio Co. - 1936-37

I actually performed this

restoration about twenty years ago. But, for this 2024

write-up, I took this 5656A off the shelf and put it through its paces

to see how well it receives here in Dayton Valley, Nevada. I also

shot all new photos of the 5656A showing the chassis in detail.

As I wrote in 2005, the 5656A is a surprisingly good receiver.

Now, in a fabulous radio-reception QTH with a large array

antenna, the 5656A does an even

better job. Although the top tuned frequency is only 18mc, the

reception on 20M is excellent. Perhaps the biggest disadvantage is

the lack of band spread. Tuning CW or SSB stations can be

difficult. |

|

General

Circuit Description

-

During the thirties,

Sears-Roebuck offered a few different communications receivers built for them by Howard Radio

Company. Their Silvertone Model 5656A was offered from late-1936

through 1937. The 5656A had a similar appearance to some of the very early

Howard-built Hallicrafters receivers, particularly the Super-7

receiver (there was also a similar looking receiver built for

Montgomery Wards.) The 5656A receiver was an eight tube superhet with three tuning bands

covering .55 to 18.0 MC. The circuit featured a 6K7 TRF amplifier, 6L7

Mixer (called a Translator by Howard,) a 6C5 LO, a 6K7 IF

amplifier, a 6Q7 Det, AVC and 1st AF amplifier, a 6F6 audio

output, a 6C5 BFO and a type 5Y3G rectifier. The IF operated at

465kc and featured a variable coupled IF transformer for

adjustable selectivity. The tuning dial was large at eight inches in diameter

with a convex glass cover with fancy "leafed" bezel.

Both the dial and speaker bezels appear to have originally been

nickel-plated but have worn to the bronze-like appearance they

now have. The beautiful multi-colored dial scale somewhat compensated for the lack of any

type of bandspread. An AVC switch was included along with a separate Sensitivity Control (IF Gain

only) and a built-in 8" Jensen speaker. It's likely that the screen-grille

was originally flocked with some kind of mohair as that was typical of

the screen grilles of the day (but, of the several vintage photos showing

various 5656A receiver grilles, some appear flocked with a

light-color felt, one had grille cloth installed and some grilles appear to just be the screen.

There wasn't any felt or glue residue on this screen which

appears to be the original.) The BFO was built on a separate small

chassis that was "cable connected" to the receiver chassis for

power but was electro-statically coupled to the detector. The

Phone jack was capacitor coupled from the 6F6 plate. The 5656A

provided the basic communication necessities and performance

that was adequate for many entry-level hams. The 5656A was

fairly popular and can be sometimes be spotted in vintage ham

station photos. The 5656A selling price was probably around

$49.50 based on that exact same selling price being asked for

either the Hallicrafters Super-7 or the 1936 Silvertone

Super-Eight (also built by Howard Radio.)

Documentation

- The 5656A is documented in Riders Perpetual Troubleshooter's

Manual, Vol. X, SEARS page 33. The basics are covered in the

single page schematic plus the side notes. The schematic is

dated 8-1-36. Although Howard Radio isn't specifically

mentioned, there are several clues to Howard Radio's contractor

identity. The schematic shows the Mixer as "Translator" which

seemed to be something that only Howard Radio called the Mixer

tube function on their schematics. The use of the 465kc IF, although

not exclusive to Howard, was the usual IF that they used. The Candohm resistor in the receiver is from The Motor Co. of

Chicago, the usual supplier of Candohm voltage dividers for

Howard Radio. There may have been further confirmation on the

rear chassis paper stickers but they are mostly missing on my

5656A. |

Silvertone Model 5656A built by Howard

Radio Co. for Sears-Roebuck

SN: 8-A 1853 ca: 1937

Delivered by Airborne Medical

Transport to Virginia

City, Nevada in 2002 |

|

Close-up of Multi-color

Dial of the 5656A |

Unusual Acquisition

- In 2002, back when I had the

Western Historic Radio Museum as a real "brick and mortar"

museum in Virginia City, Nevada, I was contacted by a ham

collector that wanted to sell me a Silvertone ham receiver. He

described the receiver as looking something like a Hallicrafters Super-7.

The price was very reasonable and he offered to deliver the

receiver in a most unusual way. It happened that Ray (the

seller) was a private medical transport charter pilot for the most of the

Western USA. He would fly people that chartered his service from Western rural areas into

larger metropolitan areas for non-emergency hospital surgeries, treatments

or appointments. The radio transaction was to take place a few weeks

later when he was

going to be flying from his SoCal home-location up to Nevada to

do a "pick up" and transport that person from a rural location in Nevada to the Reno

Airport for land transport to one of the Reno hospitals.

He wanted to come up to Virginia City afterwards since the medical

transport was a "drop off" and he only had his return trip to SoCal left. He

wanted to visit the WHRM and he also would bring along the 5656A for me to purchase. This all came off without a

hitch and the receiver was delivered as expected. The 5656A was

in very nice condition with only a couple of exceptions. First,

the grille screen was painted black and that allowed the speaker

cone to be easily seen. Then there were four knobs that were

obviously not original. Everything else looked original and later,

when I started the rebuild and could look under the chassis, I

discovered that the 5656A was all original parts. It was really

hard to believe that nothing had been changed under the

chassis,...no repairs, no modifications,...very unusual for a

relatively inexpensive receiver.

Restoration

- I performed a complete

restoration on this 5656A about 2004. I had to have four knobs

cast from one of the good condition originals. At the time, Larry Bordonaro,

now "Antique Radio Knobs.com", was just starting out and did custom knob casting in

plastic material

that looked just like bakelite. His knob castings were

first-class and indistinguishable from the originals (Larry is still in business - 2024.)

I had to rebuild the tuning system that relied on a

pinch-wheel working against a phenolic plastic drive disk. Internally,

the original paper capacitors were restuffed with polyfilms, the

electrolytic capacitors were replaced using the original cans

and the waxed cardboard box that held the two cathode bypass

electrolytic caps. The resistors were checked and all were close

to spec. I did a full alignment and the 5656A was working to its

likely specifications. The indications were that this 5656A was

used very little when it was new and was probably stored away

somewhere that preserved almost everything about the receiver (like the

proverbial "kept in a closet" example?) |

|

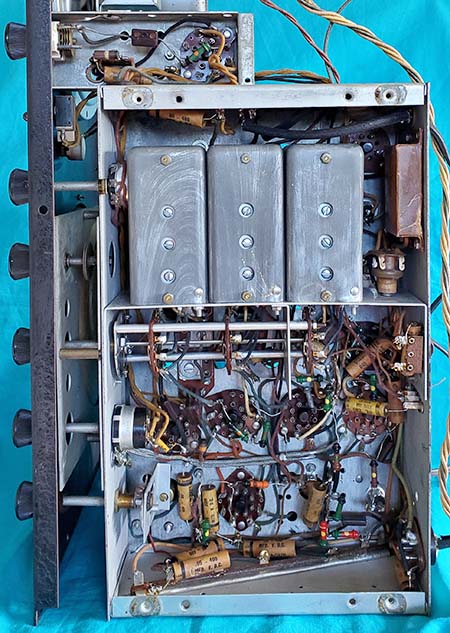

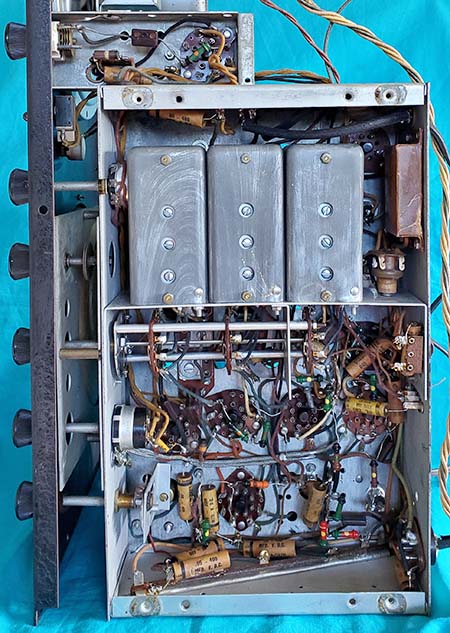

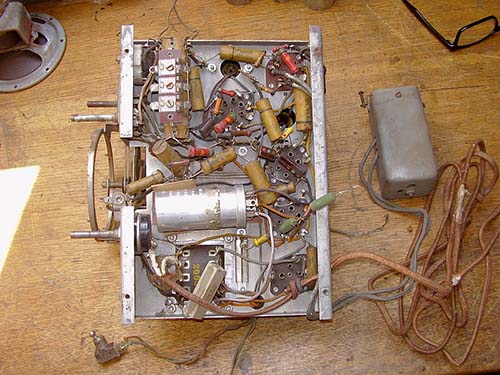

The chassis of the 5656A showing

the separate BFO chassis. The green material is felt padding for

the lid. The chassis is mounted to the bottom plate of the

cabinet and rests on rubber cushions. The front panel isn't

mounted to the chassis directly. When the receiver is taken

out of the cabinet the front panel is only held in place by the

control shafts and the knobs. The loudspeaker is an eight-inch Jensen electrodynamic

field-coil type. There are three dial lamps that can be either

#40 (155ma) or #46 (250ma) types. The steel cabinet adds quite a

bit of weight to the 5656A. NOTE: The 6V6GT is still installed

when this photo was taken. It has been replaced with the proper

6F6G tube. |

More Circuit and Operational Details

- The 5656A, at first glance, seems to

be a

typical AM-BC-SW radio that would have been for the consumer-entertainment market

and probably offered as a

console model radio. The circuit does have a TRF

amplifier stage and a single IF amplifier stage. The chassis was

professionally engineered by Howard

Radio to be built with parts and components that were the same

as those used in their consumer radios but the end product would have all of the basic

necessities of a ham receiver. The BFO chassis is an obvious

addition but it's well-designed and functions quite well. The Variable Coupled IF works from under the chassis

in a manner that's similar to how the Hammarlund Super-Pro

Variable-Coupled IF works but using a rotating pin and slider crank rather than

the Super-Pro's

cam-driven levers with spring-loaded plungers. The Sensitivity control, AVC

switch and the Phone jack are also integrated quite well with

either shielded cable or twisted wire cables to the front panel controls. Tuning is a

little crude being a small phenolic plastic disk that works with

a pinch-wheel type of drive. Without any band spread

provided, tuning is difficult especially for SSB signals (you have to fine-tune with the BFO.)

Of course, in 1937, there weren't any ham SSB signals around and

most hams were on CW. |

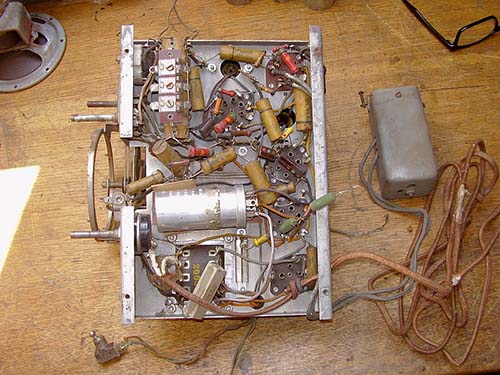

Under the receiver chassis

showing its pristine condition |

|

Under the BFO Chassis |

The 5656A does a good job on CW signals

although, like modern SSB, tuning is a little difficult but the BFO can be used for

fine tuning. Actually, the tuning dial's sweep-second hand pointer is very

handy when tuning through a ham band as it allows the operator

to "visually expand" what is really a very narrow section of the main

tuning dial. The 8" Jensen loudspeaker is a good-quality field coil electrodynamic

speaker that sounds very nice on AM signals. The

Tone control does mellow the reproduced sound considerably. |

Performance

- Years ago in Virginia City, I had thought about using the

5656A as a station receiver with a 1937 Utah UAT-1 transmitter I

had but, at the time, the receiver didn't seem to perform

with sufficient selectivity for operation on 75M phone. It was a fine SWL receiver

and the dial illumination for "lights out" listening was

impressive. Well,...that's what I thought back then when

I was in Virginia City,...one of the worst radio locations I've

ever lived in. Nowadays, in Dayton Valley, Nevada, the QTH is

one of the best radio reception locations I've ever lived in.

At some time past I had installed a 6V6GT tube in place of a

proper 6F6G tube, so before testing began, I installed a NOS

6F6G tube. Although the 6V6GT and the 6F6G can be interchanged

and function okay, the 6V6 is a beam-power pentode while the 6F6

is just a pentode. They do sound slightly different with the

6V6's reproduction in a 6F6 circuit sounding a bit shrill. The

6F6 will sound mellow and reveal a bit more bass response (geese,...I

sound like an audiophile.) When using the large Collinear Array antenna, the reception

using the 5656A is impressive for such a "basic receiver." I was

surprised at the signals I was receiving on 20M.

To demodulate SSB

signals, the Selectivity control can be used as an attenuator along with

reducing the Sensitivity control in order to have the BFO

injection to

signal level ratio correct (AVC off, too.) On 40M or 80M, SSB

signal levels can be extremely strong when using a large array antenna and even with reducing the

Sensitivity and increasing the Selectivity, still some

distortion will be experienced. It doesn't prevent demodulation

but the distortion is noticeable. When looking at the schematic

it can be seen that

the Sensitivity only adjusts the IF gain and with the AVC turned

off, the RF amplifier is running at maximum gain and that's not

adjustable. In the thirties, it was common for the ham to have a

separate "receive-only" antenna coupler that not only allowed

matching the antenna for best receive response on weak signals but would

also allow the coupler to act as an attenuator to prevent

"overloading" when tuned to strong signals. One has to

remember that most hams in the thirties were on CW and the

receiver would have the BFO on and the AVC off so overloading

could happen. The ability to attenuate an extremely strong

incoming signal was an easy method to prevent overloading. |

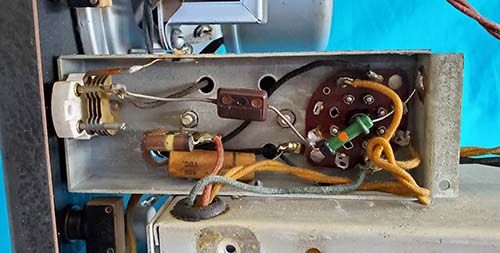

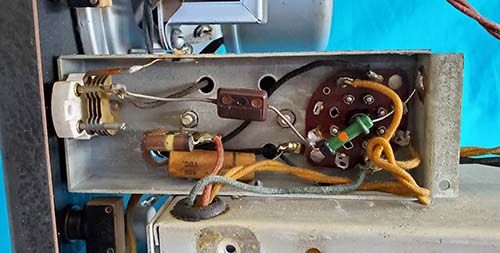

The Variable Coupled IF Control

showing the rotating pin and slider crank type of mechanism for changing

the physical distance between the IF coils to control

Selectivity. The grommet is a bit dried-out but a new grommet

might increase the "drag" and make adjustment difficult. It

works fine now. |

|

This intense level of signal wouldn't happen when using a

smaller antenna but I'm testing using my large Collinear Array

that has some gain, so it's the "worst case scenario" for trying to

successfully demodulate extremely strong SSB signals on 80M and

40M. SW-BC signals are easy to tune

in and sound very nice although it does depend on the broadcast

material. When in Virginia City, I used a

60' EFW with this receiver and the combination of poor location

with an even poorer antenna didn't provide very impressive

results. But, a RF-friendly QTH and a large antenna system will help any receiver, so

the 5656A went from unusable to a receiver that could easily and

successfully be

used on 75M AM. For SWLing, it seems to perform quite well and

will easily receive stations up to the 19M band and even 16M SW

stations are easy to receive with the upper limit of tuning

being 18mc. As would be

expected by looking at the dial, the tuned frequency accuracy is

vague at best and resolution is extremely limited. Most hams at

the time would have had a separate Frequency Standard (a 1000kc,

100kc and 10kc oscillator) that could provide a check on band

edges. Many hams, especially entry-level hams, would have used a

crystal-controlled transmitter and would know their operating

frequency, although on-the-air QSOs were usually somewhat

"split-frequency" because of the multitude of crystal-controlled

transmitters. There isn't a remote standby provided but there is

a front panel standby switch.

As to disadvantages when using

the 5656A,...the lack of band spread is foremost and makes

tuning in CW or SSB signals relatively difficult. Using the BFO

for fine tuning helps. The tuning dial's lack of resolution and

very small ham band spans doesn't help the tuning situation. This

again relates to the lack of band spread. Using the split-second

hand to concentrate your vision on that scale will give the

impression that the ham bands have a little more span. It helps

quite a bit but still covering all of 20M only takes from 50 to

56 on the split-second dial. Overloading on strong signals can

be a problem but it depends on the antenna size and gain. Using

the Selectivity as an attenuator works most of the time and more

selectivity doesn't hurt on CW and SSB. All in all, the 5656A is

a decent performer with some limitations that should be expected

for the time period in which it was produced and the design

limitations due to its relatively low selling price (it's

difficult to imagine but $49.50 in 1937 is equivalent to

$1075.00 today in 2024,...WOW!) Though it

certainly could be used as a vintage ham station receiver on

75M, its success would depend on the user's motivation and

experience with using pre-WWII receivers "on the air."

|

Sears-Roebuck -

Silvertone

STANDBY - Model 5752 - built by

Howard Radio Co. - 1940

The Model 5752 is a nine tube, single preselection superhet with two IF amplifiers, crystal filter, electrical

bandspread, R-meter, switchable AVC, BFO with front panel frequency

adjustment and a single-ended 6V6 audio output all built onto a copper

plated chassis. Tuning range is in five

bands covering .55mc up to 40mc. An external speaker was required. Dials

were illuminated but the R-meter wasn't. Dates from 1939 to 1940. The

Model 5752 was built for Sears by Howard Radio Company.

One certainly notices the similarity of the

Silvertone

STANDBY's appearance to that of the Radio Manufacturing Engineers

RME-69. It had to be a deliberate design "copy" of the RME-69 but what

would have been the reason? A clue might be in the name "STANDBY." At

the time, many hams believed they should never be without receiving

capability. If the main receiver was down for repairs, then the

"standby" receiver could be used. The active and prepared ham would always have a "standby" receiver.

If the station receiver was a RME-69 or RME-70, then this Sears "look-alike" would

blend in and appear to be another RME product. It seems unlikely that

Sears' "RME-69 look-alike" would have been styled to fool someone into

thinking this Howard-built receiver came from RME, especially at the

price Sears was selling it for. It's more likely that the designers

imagined that a ham looking for an inexpensive "standby" receiver would

find the Model 5257 appealing because of its familiar appearance.

No restoration has happened on this "STANDBY" receiver,...at

least, not yet. One can note that to the left of the tuning dial

escutcheon there is a small red pilot lamp jewel. This superfluous addition will be

removed as soon as work starts on this receiver. It's obvious

that some mechanical rework is going to be required since the

dials are obviously tilted somewhat. More to come,... |

Silvertone STANDBY

Model 5752 built by Howard Radio Co. ca: 1940

RME-69 look-alike, minus the RME price,...and

performance |

| This Silvertone

STANDBY receiver had belonged to KB6BKN Walt Schivo (in

fact, Walt currently has a photo of this receiver on his QRZ page.) For a

while, there were some Internet postings about this very same

receiver with speculation that it was a RME product. Walt sold a

lot of his gear to Ham & HiFi about five years ago and that's

where I found the receiver in July of 2019. Once I had the receiver and could thoroughly examine it

didn't take too long to discover that it had been built by Howard

Radio Company. |

|

Howard Radio

Company - Model 437A - 1940-42

The Model 437A was the last

evolution of the 435 and 436 models of nine tube receivers that

were mid-level communication receivers. The 437A covered .54mc

up to 43mc in four tuning ranges with band spread capability.

The IF operated at 465kc and there was an optional Crystal

Filter and an optional S-meter. This 437A has the Crystal Filter

option installed but not the S-meter. As the 437A with Crystal

Filter, the selling price of the

receiver shown would have

been $69.75 in 1941.

Many of these

smaller models of

Howard receivers had a matte silver-based chemical treatment for

the dial finish that nowadays is

almost always is found in terribly corroded condition. This particular

437A's dial is in excellent condition (it may have had a

protective coating applied when manufactured but more likely the

pristine condition of the dial is due to the dry climate here on

the East Slope of the Sierra.) In fact, the entire

receiver was cosmetically in very good condition and the chassis

was essentially original. Unfortunately, although I took the

time to clean this 437A and photograph it, I didn't restore it

to operational condition. In fact, I sold this receiver quite

some time ago (and I don't even remember who bought it since I

sold it "out of the museum") but at least I did keep the photograph. |

Howard Model 437A with Crystal

Filter option ca:

1941

A transient relic now in

other hands |

|

Howard Radio

Company - Communication Receiver Model 450A - 1938-39

I was tipped off that this Howard 450A was

going to be at the May 11, 2024 Spring SNARS (Sierra Nevada Amateur

Radio Society) "Cabela's Swap Meet" - so called because the ham

swap meet is held in Cabela's parking lot in Verdi, Nevada (10

miles west of Reno.) The 450A was part of a very large selection

of some really nice "collector" ham gear that was brought to the

swap in a 14'

moving van by Ham and Hi Fi of Sparks, Nevada. Of course, at a swap

meet you have to "take your chances" since a detailed inspection

isn't really very practical - "as-is" or "as found" is the

expected and typical condition. However, the 450A looked very complete and the dial was

magnificent, so the purchase was made. This write-up has a lot

more information than the proceeding restoration write-up on the Silvertone 5656A since this write-up was composed as I was

restoring the 450A receiver. So, expect the typical OCD-type of

restoration write-up presenting every bit of minutia I find

(with many photos.) How the multitude of minor problems were corrected

will be covered and

eventually how well (or poorly) this Howard communication receiver performs.

|

|

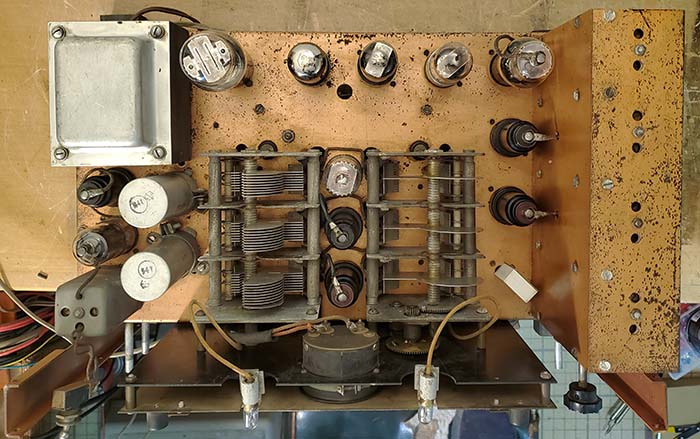

The Model 450A was one of Howard's largest

communication receivers at 12 tubes and a tuning range that

spanned .54mc up to 65mc in six tuning ranges (only the Model

490 had more tubes at 14 total.) The Model 450A was one of a

few receivers available at the time that tuned the 160M through

10M ham bands and included 5M coverage. The smaller Model 440 was nine tube

receiver with a similar appearance but without 5M coverage, the dual IF,

push-pull audio, the "stop watch-like" band spread logging

dial,

the band-in-use indicator and, like many of Howard's larger

receivers, the crystal filter was an optional

installation.

The Model 440 sold for $84 in 1938. The Model 450, also from

early-1938, featured additional tuning ranges increasing the coverage up to 65mc

however when going to bands E and F a different IF of 1560kc was used and the RF

amplifier was

bypassed on the highest frequency band since the 6K7 RF amplifier

tube didn't have very much gain at VHF. The Model 450 sold for $87

and $10 extra if the crystal filter was installed. The Model

450A was introduced within a very short time as the Model 450's

replacement (still in 1938.)

The Model 450A had basically the same features

as its predecessor but now the band F antenna input actually was

a TRF transformer to the Mixer grid where before it had just been a LC

input. The VHF antenna terminal had been A-G two-terminal and

was now A-D-G three terminals. The dual IF of the 450 was

basically unchanged for the 450A. The ABCD IF was 465kc

(frequency coverage from .54 to 16mc) and the EF IF used the

same 465kc IF amplifier tubes but had entirely separate IF

transformers that were tuned to 1560kc and switched into the IF

circuitry the Crystal Filter/IF Shift switch. Frequency coverage

from 16 to 65mc was available on bands E and F. The 1560kc IF helped

reduce the rampant images

that would be encountered on bands E and F. With single preselection (one TRF amplifier,) images on

A,B,C,D bands

probably wouldn't be encountered until around 15mc, depending on the antenna

used and the strength of the signal producing the image. With

the 1560kc IF use (beginning at 16mc,) images would appear 3.12mc

below the transmitted frequency which tended to put the image

response out of the passband of the receiver's front end

selectivity, especially with band E also having a preselector

stage. Two separate sets of antenna terminals are provided on the

back of the chassis. Both are three screw terminal types marked

A-D-G. One antenna input is just for Band F (5 meter band-VHF.)

A vertical whip antenna 59" tall is recommended (with an 8" wire

connection to the antenna terminal) for 5 meter reception. The antenna input for Bands

A-E is for any type of standard balanced or unbalanced antenna

(with resonant antennas providing the best performance.)

The

crystal filter was switched out of the circuit when IF SHIFT BAND

E-F was selected (that eliminated the need to have two crystals,

465kc and 1560kc,

in the Crystal Filter circuit.) The BFO had a variable injection

level adjustment in addition to a frequency control (pitch.) The

1st AF amplifier used a bias cell for the grid (these were

popular in the late-thirties and were very small batteries that

fit into a special holder, some were solder-in types, usually providing about -1.5vdc bias voltage.) A phase

inverter type of audio circuitry was used. The audio output used

push-pull 6V6 tubes and 9.5 watts output was claimed with

impedance outputs of 5Z and 500Z from the internal audio output

transformer. The entire chassis and shielded box for the IF

amplifier/Xtal Filter are both copper plated. A 10" PM loudspeaker was

available in a matching housing. >>> |

|

Howard Communication Receiver Model

450A ca: 1938 "as

found condition - May 11, 2024"

The

industrial-scientific instrument-type dials appealed to

techno-minded hams but note that the glass dial cover has

slipped out of its mounting clips and the top edge of the glass

is showing. |

| >>> Selling price for the 450A was $95.45 and with the optional

crystal filter installed the price was $105.45 in 1938 and 1939. The selling price of $105.45 put the Howard 450A at about the

same price as the larger Breting receivers (the 14AX or the 40)

and the Patterson PR-15 that was then being built by Pierson-DeLane.

The larger communication receivers from the big three, National,

Hammarlund and Hallicrafters, or even RME, were typically at least 50% higher

in cost, so price was certainly an important factor in the

Howard 450A sales. But, even $105 in 1938 was quite expensive

being equivalent to about $2200 today (2024.) Besides the

comparatively low price, there was the

attraction and the visual appeal of the 450A with its impressive

dials looking like whirling stop watches, pressure gauges and barometer

needles.

The 45kljhlkjh0A's industrial-scientific instrument-type appearance must

have prodded prospective techno-minded ham buyers with their

purchasing decision. |

|

| The Dual IF

Function - The IF on Bands E and F, or 16mc up to

65mc, operates on 1560kc. This 1560kc IF uses two dedicated IF

transformers that are specifically for 1560kc and function with

the two 6K7 IF amplifier tubes. When selecting to either Band E

or Band F, the IF isn't switched along with the Band Switch

function. The operator must also place the Crystal Filter

switch to "IF SHIFT BAND E-F" and the BFO SHIFT toggle switch

has to be placed in the E-F position, if the BFO is to be used.

When using Band A, B, C or D the 465kc IF must be used. The

465kc IF has two dedicated IF transformers specifically for

465kc and they will function with the two 6K7 IF amplifier

tubes. For these bands (.54 to 15mc,) again, the band switch

doesn't change to the 465kc IF amplifier circuitry. The operator must set the Crystal Filter switch to either BROAD or SHARP for no

crystal filter or to XTAL IN for crystal filter operation. The BFO

SHIFT toggle switch has to be placed in A-B-C-D for 465kc

operation. Documentation

- Fortunately, the Howard 450A is documented fairly well in

Rider's Perpetual Troubleshooters Manual Vol. X, pages "HOWARD

PAGE 10-28 to 10-31." The pages include the schematic, the

component layout for both the top and bottom of the chassis,

color codes for the transformers, receiver specifications and the

alignment procedure. There are many online sources to view any

of the Riders PTSMs. The easiest to use is at

www.worldradiohistory.com with all of the Riders manuals

(selectable by Volume number) in PDF format. Unfortunately, BAMA edebris doesn't have an

online manual or any documentation on the Howard 450A.

|

| Dial Details

- The dials are glass with multi-color silk screened

nomenclature on the back side. With the matte silver back plate,

the glass dial is spaced slightly above the silver plate giving

the appearance of depth. The illumination

is from the top edge of the glass using two #47 lamps. The main

tuning dial scale has color coded indicators on the linear

scales with red for amateur, blue for aviation, yellow for

police and green for shortwave relay broadcasts. Some 450A

receivers had black back plates and were fitted with the glass

dials that had white nomenclature along with the red, blue,

yellow and green dial scale indications. The convex dial cover

is also glass. The stop-watch logging pointer is recessed

slightly making it appear as a separate indicator scale. The "band-in-use" indicator

is an white-on-black plastic scale mounted to the band switch

shaft and shows through a hole in the silver back plate. The

"band-in-use" indicator also shows which IF should be used for

the particular band selected.

The "R" meter is also mounted behind the silver metal plate and shows

through a hole. A close-up of the dial is shown to the right. 450A Tube

Line-up - RF Amplifer - 6K7, Mixer (called a

"TRANS" on the schematic - Translator, a Howard

moniker for Mixer) - 6L7, HF Oscillator - 6J5G, First IF

Amplifier - 6K7, Second IF Amplifier - 6K7, Detector/AVC/First

Audio Amplifier - 6Q7G, BFO - 6J7G, Voltage Amplifier (R-meter)

- 6J7G, Audio Phase Inverter - 6J5G, Push-Pull Audio Output -

6V6G (2), Rectifier - 80. It's interesting to note that many of

the tubes that could use metal octal types are specified as "G"

or glass envelope tubes operated without shields (pin 1 is

grounded so metal tubes could be used and shielding would then be

provided.) Some receiver designs would use glass tubes for

oscillators because the glass envelope without a shield would run cooler than a

equivalent metal octal version and might possibly have less

thermal drift. The Detector/AVC/First Audio

Amplifier would operate at a fairly high level signal and shouldn't

pick up any noise so the use of a glass tube might have been for thermal reasons.

In almost any vacuum receiver, the audio tubes and the

rectifier will almost

always be glass tubes because of the heat involved with their

operation. |

450A Glass Dial - A Multitude of

Indicators |

| Preliminary Inspection

- May 18, 2024

- The 450A chassis shows signs of endless repairs that were

accomplished at a "worse than amateur-level workmanship" both in technique and ability.

It's obvious that the Candohm resistor was

open and has been repaired poorly with sloppily installed

resistors replacing the open sections. The 2.5K 0.5W section of the Candohm

was replaced with a 10 watt vitreous-enamel coated Ohmite

resistor, certainly "over-kill" and showing the lack of

comprehending the basics of Ohm's Law on the part of the repair

technician. Most of the capacitors have been replaced with a

variety that is either because of repairs using "junk box parts"

or that the repairs took place at different time periods. Fairly

modern Orange Drops are installed here and there implying that

some repair work was performed in the last couple of decades.

The few vintage capacitors remaining are Aerovox brand but even

they aren't original to the 450A. The electrolytic

"metal can" capacitors appear original but have a USN "anchor" stamp on top,

so they are more than likely very old replacements

since they are both dual 8uf cans. The schematic shows a single

8uf can and a dual 8uf can being used originally.

I checked

the power transformer and it's a physically

smaller replacement

that doesn't quite fit correctly. Two pieces of 1/2" steel channel

are used for mounting adaptors making the replacement obvious.

This transformer does have close to the standard voltage

outputs but it appears too small for a 12 tube radio set (should

be HV 375-0-375vac ~.120ma, 6.3vac~4.25A, 5.0vac~2.0A.) This power transformer

looks like it was for an eight-tube set. The original power

transformer was probably a Stancor since they, like Howard, were located in

Chicago. It shouldn't be too difficult to find a correct spec Stancor power transformer. The filter choke tested

okay.

The audio output transformer has an open plate to CT

winding. It's the dual secondary of 5Z and 500Z with a rating of

about 10 watts that makes an exact replacement difficult to find. The

closest that I can find (in my stock) would be out of a National

HRO-60. This audio output transformer is for P-P 6V6 tubes and

has a secondary for 8Z and 500Z. It's a frame-type transformer

and should be a fairly close fit. Another "Howard issue" is that

the original audio output transformer and the filter choke are

both mounted using rivets compounding the replacement task. |

Mechanical Inspection

- The entire chassis is copper plated and the copper is in

pretty good

condition with just a few small corrosion spots. The entire IF

shielded box is also copper plated and in fairly good condition.

There's a non-original punched hole in the rear apron of the chassis that may

have been for an auxiliary socket. There's also a 1/2"

hole on top of the chassis behind the tuning condensers. I

doesn't appear to have any function and doesn't look original.

Both holes are very neatly done (unusual.)

Typical of some receivers designed at this time, the tuning

condensers are mounted on rubber cushions which have compressed

and dried out. The rubber bushing mounting of the tuning

condensers involves the entire front dial backing plate with the

front of the MT condenser and the BS condenser mounted to the

plate, then the plate is cushion-mounted to the front chassis

apron and the rear of the MT and BS condensers are mounted to

the top of the chassis with cushions. This arrangement allows

replacing the cushions without unwiring the MT and BS

condensers.

The RF Gain control shaft is extremely worn and

wobbles quite a bit. The AF Gain control is not worn. The BFO

air variable has a strange "feel" to it,...it's like it's rubber

mounted but it isn't. Further investigation will be necessary to

see what's going on with the BFO.

The Main Tuning uses dial cord

for the drive but the Band Spread uses a tuning belt. Belts are

always difficult to replace and even if the correct belt is known (JFD

#21 in this case) it may not fit correctly because of wear. The

450A has the MT/BS condensers mounted to the backing plate and

both tuning shaft bearings are in the same backing plate so the

dimensions can't change, therefore, a belt with an inside

diameter of 3.5" should work. Using square rubber extrusion

works fairly well for custom rubber

belts that are cut to size and then glued with super glue.

However, they

don't last indefinitely. Likewise,

O-rings will only work for a short while before drying out and

breaking (O-rings aren't designed as "belts" so it's not

surprising that they don't last very long in that function.) The original belts lasted a long time because they were

a fabric sandwich with impregnated rubber. The trouble is, these

belts are at least 70 years old, so they might be non-pliable

nowadays.

The glass dial is in perfect

condition. The champagne-silver backing plate is excellent. The glass dial

cover needed some padding where the clamps contact the glass.

The pads allow tightening the clamps to slightly compress the

padding and secure the glass without breaking it. The receiver front

panel is in very good condition and the cabinet is in good

shape. The bottom cover is missing but would be easy to

replicate. |

| Past Repair Work

- Often times "worse-then" amateur-level repairs do more damage then actually

repairing anything. When dealing with low-cost, high tube-count receivers, such

as the Breting 12 or 14 and the Patterson receivers, it seems

that these receivers required many more repairs than comparable receivers from

the Big Three (National, Hammarlund and Hallicrafters) or RME. I'm not sure why this is happens but the

quality of components doesn't seem to be a factor. The passive

components are name-brand parts,...same as used by the Big

Three. The exception might be that the power transformers used

were rated for intermittent service, which is common for

consumer-entertainment radios, and then the ham-owner exceeded that

operational limitation by having the receiver powered-up for

hours-on-end. Also, often problems discovered seem to have

been caused by carelessness or inexperience resulting in circuit

component damage on an extensive level. Most of the problems

seem to have been with the power supply section and the audio

output section, which is where the components are "pushed" to

their maximum ratings and where most failures would naturally

occur. Although one does run

into these types of problems on National, Hammarlund,

Hallicrafters or RME receivers once in a while, the low-cost,

high tube-count

receivers from Breting, Patterson and, apparently Howard, all seem

to suffer from what seems like a litany of endless repairs that were accomplished by

amateurs with little or no experience in troubleshooting or in

the proper techniques of repair work. In almost all cases, these

receivers will not function correctly or don't function at all.

The Plan - The

Howard 450A is going to require a complete "strip out"

of the old sloppy repairs, the incorrect parts, the

modifications and the defective parts. This is usually what has

to be done with ham radio "kits" but so much of the 450A has

been tampered with, it almost has to be treated like it was a

"kit" that was assembled by someone lacking any experience. The

original sections of wiring will remain installed. Any original

components that can be used (tested in spec) will be used but

all replacement components will be of the original style and

vintage that test as usable. Then the chassis will be rebuilt

exactly to the schematic with component placement as shown in

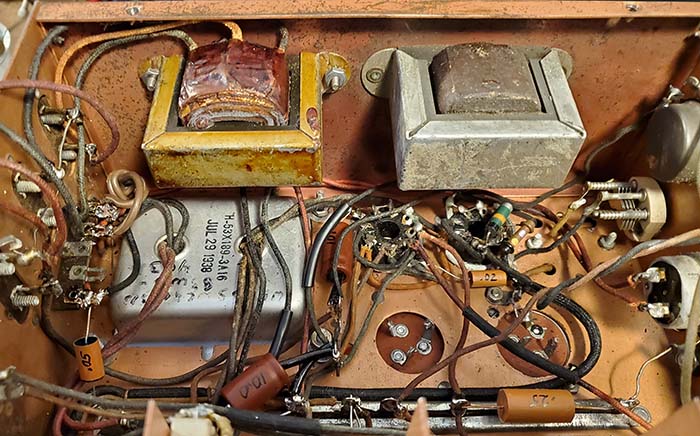

the layout drawing. >>> |

|

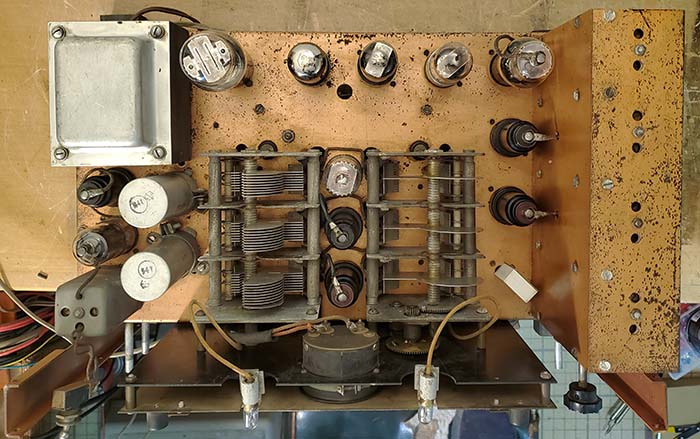

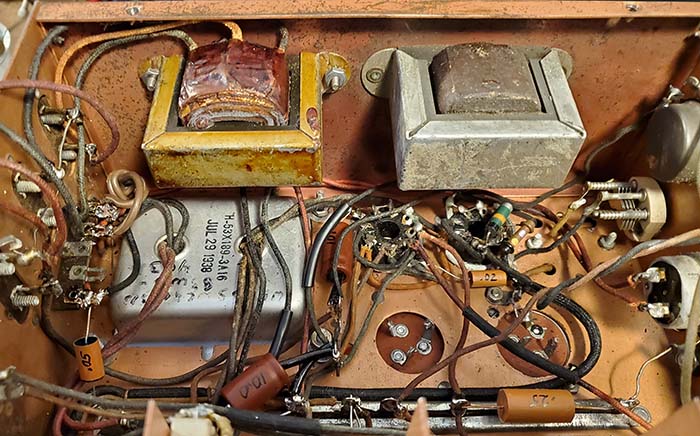

Under the chassis of the Howard

450A with the under-size power transformer removed and the bad

audio output transformer removed. Note the many non-original

capacitors and resistors besides the terrible wiring lead dress. A

lot of that "messy looking wiring" is original. Howard routed

some wiring in a harness but most wiring is "point to point." |

>>> All paper dielectric capacitors

will be polyfilms installed into vintage Aerovox shells to

preserve the under-chassis appearance as much as possible (this

is just a "plan." UPDATE: The Aerovox

caps are replacements, the original Howard capacitors of which

only two have survived just have a value and part number, no

manufacturer shown.) For the audio output transformer,...the transformer from the HRO-60 is perfect. It's the same

physical size as the original Howard transformer and has

nearly the same specs. The primary is for P-P 6V6 tubes and the

secondary is 8Z and 500Z, so it's a very close match. The original

power transformer dimensions were 3.5" x 4.0" and it was a

tub-mount. So far I've found one power transformer that is very

close for all of the necessary windings but it has one extra

winding that produces about 25vac. This transformer is the

correct size but uses four bolts for mounting where the original

power transformer used two bolts. The replacement xmfr is

ink-stamp dated

July 29, 1938 and has a hand-written note indicating it came out of a

large Wards

(Wells-Gardner)

radio. Some of the 13 and 15 tube W-G radios had a 25vac winding for

four series wired 6 volt tubes. This W-G transformer will work

and would look stock but I still have many other power transformers to

go through and I might find one that's an exact match.

Cleaning Begins -

For now, I've cleaned the chassis with WD-40 followed by Glass

Plus. It was actually quite dirty and responded well to the

cleaning. I had to replace the two front rubber bushings that

mount the tuning dial backing plate. The original rubber bushings had

disintegrated so the backing plate would move around. The top

chassis rubber bushings for the rear mounting of the MT/BS

condensers were in good condition. I ordered a JFD #29 tuning belt.

If that works, I can reassemble the tuning

dial.

Belt Update - May 25, 2024 - The

JFD #29 tuning belt arrived today and, while it's not

what's called for in the JFD index (#21 is,) I went by what I

measured. The JFD #29 was 11" inside circumference or 3.5" ID.

The fit was perfect but the belt kept derailing while tuning.

However, when I mounted the front dial plate that provides the

front bearing for the tuning shafts, then the shaft was

perfectly horizontal to the vertical pulley on the BS condenser drive and

the belt then functioned correctly and didn't derail. |

| Stripping the

Chassis of Undesired Parts - May 26, 2024 - I removed the defective audio

output transformer by drilling out the rivets. The wire leads

were clipped at the bad transformer because I will use them to

extend the leads on the HRO-60 transformer. I unsoldered all of

the wire leads that were from the undersize power transformer.

The transformer was then dismounted and removed. When it was

placed next to the W-G replacement transformer, the size difference was

surprising with the W-G being about 50% larger (yet it fits into

the chassis opening and aligns with the "shadow outline" from

the old "long gone" original.) The only problem is

that the W-G requires four corner holes for mounting where the

original used two center-side mounting holes (and there

aren't any center holes in the W-G xmfr.) I still have a few

more transformers to look at but so far the W-G is the best

replacement other than requiring drilling four mounting holes. (No

exact replacement was found. The transformer I'm going to use is

probably from one of the 13 or 15 tube W-G radios. These radios

had a 25vac winding for four 6.3vac tubes wired in series. The

25vac winding isn't

necessary for this application and the regular 6.3vac winding

can supply the filament current needed for the 450A. The +HV

winding is typical for P-P audio applications rated at 8 watts

being about 370-0-370vac (with 120vac on the primary.) With the rectifier voltage drop and

the IR drops involved, the resulting B+ at the 6V6 plates should

be around +250vdc but this is also dependent on the AC line

operating voltage which probably should be 115vac for this

receiver.) Next is to remove all of the modern parts installed. To make

reassembly easier, I'll take a close-up

photo for reference. Usually, when doing a "strip-out" on a

ham-kit receiver, the documentation will have a detailed drawing

of all of the components and wiring as part of the assembly

instructions. The 450A wasn't a kit, so the only drawing shows

just the placement of the capacitors and resistors without any detail

on wire routing. The photograph with the schematic

and Howard's component location drawing will all be used when

doing the reassembly.

Any modern resistors that are replaced with correct vintage resistors

will have to have the vintage resistor values checked. I have a

large quantity of late-thirties "dog bone" resistors that are NOS. Over half

of the resistors checked have drifted in value by 50% and some

are 100% or more higher in value than marked. Many of the

original resistors are still present under the chassis but those

will have to be checked for drift. The original resistors seem

to be all "dog bone" types except for three straight-end BED

resistors but with a color band replacing the dot (not the

normal color-band configuration.) Those three straight-end types

appear to be originals and are (2) 50K and (1) 500K.

|

Showing the type of

sloppy repairs performed on the voltage divider sometime in the

past. The obvious "over-kill" 10W Ohmite resistor with a ring of

glopped-on solder is the B+ input to the Candohm. Black

electrician's tape, hook splices and tack soldering show

that this is worse-than-amateur-level work. Due to a multitude of errors, the receiver never could have worked afterwards

(but almost certainly the perpetrator blamed Howard for

building a such a "crummy" radio.) |

| The Candohm

Voltage Divider

- Candohm dividers always

were very prone to opening up on the various sections. Usually,

an associated bypass capacitor would fail and the increased

current would exceed the wire wound sections and one or more

sections would open up. Most repairs would parallel a new

resistor connected to the terminals of the open section to make

the repair. This approach would probably result in the neatest

appearance since finding an original Candohm would be impossible

and repairing the bad Candohm would require rewinding the

burnt-out sections with new ni-chrome wire and that could only

be acccomplished if the original could even be taken apart (they

weren't designed for repair,...just replacement,...and maybe not

even that since it's riveted to the chassis.)

It's really quite

easy to calculate the entire Candohm divider network and the

dissipation requirements. First, total all of the Candohm resistances

(17.6K.)

Observe what the B+ level is at the input to the Candohm

(+245vdc under load,...+305vdc at the rectifier, IR=60vdc across

365Ω choke=~160mA total B+ current draw.) Then

I=E/R will give the total current through the Candohm (245/17,600=14mA.) The I²R=P

will give the dissipation of each resistance in the Candohm. The

TOTAL dissipation across the entire Candohm is about 3.5

watts (so 10W for one section was definitely "over-kill.") The

greatest dissipation is the 10K section at 2 watts (and that

section is okay.) Generally, dissipation (watt rating) is

doubled as a safety factor since the calculations are based on

the receiver operating with normal current draw but at "turn on"

much higher voltages will be experienced (although less current)

until the tubes warm-up and start to draw current off the

divider taps. Since the

resistance values are already known from the schematic, only the

dissipation of each section is in question. The current draw of

the operating circuit off of each Candohm tap also affects the

total current through the divider to a certain extent but for

dissipation requirements, the static voltage drops will be close

enough.

The affected resistor in the 450A Candohm is the open input

resistor that can be replaced with a 2.5K 6W (.5W actual

dissipation.) The 1.5 section is okay (.3W,) the 3.6K section is

okay (.72W) and the 10K section is okay (2W.) The dissipation

levels shown in parentheses are calculated with +245vdc B+ (from

schematic) and are probably slightly lower than if the receiver

was operated on 120vac line voltage (the +245vdc was probably

specified with 110vac to 115vac line voltage.) >>> |

Howard 450A Top of the Chassis

(W-G replacement Power Transformer

Installed)

Note the Band Spread condenser only has one rotor plate and one

stator plate per section. This "Howard" modification is shown in the Rider's PTM

information and indicates that one rotor plate and stop per

section can be removed to

reduce vari-C and thereby increase the "spread" for better fine

tuning response. Unfortunately, this mods RUINS the band spread

action entirely. |

| >>> But, even if the B+ actually was +330vdc as the

receiver was "warming up" before the tubes start to draw

current, the resulting total Candohm static dissipation

only increases from 14ma to 18.75ma and the 2.5K or the 1.5K resistors'

dissipation only increases a few tenths of a watt (total

Candohm dissipation at +330vdc would be 5 watts but it would

only be for about 15 to 25 seconds.) The result is a lot of

variables that aren't going to affect the overall function of

the voltage divider. The replacement resistor can have a much

higher dissipation rating and, with modern resistors, their

physical size is quite small. So I could use the exact

resistance value that was required, I ordered an older NOS

replacement wire wound resistor. Even though the replacement

resistor has a 6W dissipation, physically, this type of resistor

is only 1" long and .250" diameter, so mounting it on the Candohm terminals won't be too

obvious of a repair (conveniently, the resistor is black and

that also helps to hide its installation.) |

| Push-Pull 6V6 Specs

- For around 10 watts output power,

the 6V6 plate voltage should be around +250vdc. The screen

voltage will also be around +250vdc. The grid bias is determined by

the value of the cathode resistor (250Ω) resulting in about

-15vdc bias that shows up as +15vdc on the cathode. W-G Power Transformer

Installed - May 28, 2024 - Just a very slight

adjustment of the square hole was necessary for this replacement

to fit. About .090" was removed from the front-most short side and that was

enough for the transformer to "drop in" the tub hole. I marked

the four holes necessary for mounting, drilled them and then

mounted the W-G transformer. I tested the transformer several

times just to be sure that the removal of the 25vac leads

(cutting, insulating and placing the leads inside the bottom

cover) didn't

cause any problem and to verify the operation of the transformer

was as expected. I didn't wire in the W-G transformer yet since

I still need to "strip out" the modern components and

sloppy repairs

first.

|

The Audio Output Transformer

- This transformer is from a parted-out HRO-60 receiver with a

P-P 6V6 audio output stage. The specifications for this

transformer are almost perfect as a replacement and, physically,

it's exactly the same size as the defective original.

Installation was straight-forward with no problems. Since some

of the HRO-60 transformer's leads are shorter than what was

required, I had to splice the original transformer's wire leads

to get the length needed. Although one would first think that

shrink tubing should be used to insulate the splices, shrink

tubing looks "too new" (because it is.) In the late-thirties splices

were insulated either with friction tape or with lacquered

tubing. I used the lacquered tubing if possible and friction tape

as a second choice. More

Stripping - May 30, 2024 - I removed all wires going to the

Candohm. Several were not connected to the correct voltage taps. I

marked all wires (wrapped tape ID) after verifying were the wire came from so, when

reconnected, the circuit will have the correct voltages. I found

a wire going to the LO tube socket that was a broken solder

joint. This was under the coils and would have been almost impossible

to spot except I was tracing wires to the LO and happened to see

the broken joint when I moved the wire slightly. Luckily, there

was sufficient spacing between the LO vertical shield and the LO

coils to access the tube socket and the wire was soldered back

onto the socket terminal. Removed all components and wiring to the rectifier

socket and both 6V6 sockets. Only one resistor was original. 6V6

cathode resistor was a replacement that wasn't the correct value. |

| Wire Harvesting

- I'm sure I'll be needing some vintage hook-up wire as I

rebuild the 450A. The hook-up wire is solid conductor 22ga. TC

with "push-back" cloth insulation. Almost identical wire was

used in Hallicrafters receivers about the same time. I have

several SX-28 "junk chassis" that can provide this type of wire

in the correct color insulation. Having ample wire supplies will

allow for proper routing when doing this rebuild. Lead

Dress - The Howard 450A component drawing shows

the proper placement of the capacitors and resistors.

Unfortunately, it's obvious that Howard's assemblers didn't

install ALL of the components exactly as shown on the assembly

drawing, so there will be a few capacitors placed differently

but they are "as originally installed." Some of

the wiring in the chassis uses a harness. The other

wires look randomly installed. Comparing the original wiring in

the Silvertone 5656A to the 450A, it appears that Howard wired

the tube heaters and some of the B+ in the harness while the

signal wiring was "point to point" wiring. At the time, "point

to point" was a lead dress style that believed that the

shortest, most-direct wiring resulted in less capacitive

coupling in the signal circuit so less losses and better

performance resulted. I'll be rewiring the 450A in this manner to

adhere to "Howard's style" of wiring.

Capacitors -

Since so much of the under-chassis isn't original I don't think

there's really any point in restuffing the few remaining

original caps and adding non-original shells into the mix. So,

I'm going to use yellow-jacket polyfilms but, as I've done in

the past, I'm going to paint the capacitors to hide the hideous yellow color of the modern capacitors.

Resistors needed will be as close as I can find to the original

style. The effect this creates is at first glance the under the

chassis appearance is that of an original receiver. Close

examination would easily show that the painted capacitors were

obvious replacements. |

Power Transformer and Audio

Output Transformer - Jun 7, 2024 - Wired the

power transformer into the circuit. Mounted the HRO-60 audio

output transformer and wired the secondary into the circuit. I

had to recondition the Phone Jack wiring and reconditioned the

wiring for the Standby switch. Routed all of the B+ wires to the

proper terminals on the Candohm resistor. Installed the 2.5K 6W

WW resistor to the open terminals of the Candohm. This resistor

is very small for its dissipation rating and even that 6W rating

is over ten times what's actually needed (it was the smallest

dissipation resistor that was convenient to order.)

Side-Tracked - June 1, 2024

- The N7RCA Minden Swap Meet had a few of impacts on this

project. First, I had to get a SCR-511 "Pogo Stick" WWII

transceiver packed and shipped to North Carolina. Then I had to

do a "quickie repair" for KB6SCO of a National NC-183D receiver that was

going to be given to a newbie SWL. Then I made

a purchase at the swap of a Linear Amplifier that had been built

by W6MIT (this was a case of "mental side-tracking.") These

events delayed the Howard 450A project for about a week (and

the MIT-linear is intermittently continuing with its

interruptions.)

Jun 8, 2024 -

Completed wiring of the audio output transformer. Extensions had

to be added to the plate connections to the 6V6 tube sockets.

The splices used helically-wound 24ga TC coils that were used

for "soldered butt joints." That way the sleeving could be

installed over the joint and it would appear original.

Jun 9-11, 2024 -

Continued removing non-original parts and installing vintage dog

bone resistors that are checked for correct value. Correcting

errors (this 450A would NEVER have worked after its

last "hamstering" job) and removing solder bridges (due

wrapping component leads around terminals and glopping solder

everywhere,...example,...the 2nd IF amplifier screen was shorted

to ground with a solder bridge on the bypass capacitor. Had

power ever been applied, the screen load resistor would have

"smoked." )

There's something about the solder too. Either it's some sort of

"no lead" solder or else all of the non-original solder joints

are "cold solder joints." The solder just "clumps off" when

heated. It wasn't adhering to the terminals at all. Also, found

several joints where the solder wasn't flowed properly and there

wasn't any contact with the lead that was just wrapped around

old cut leads from the old removed parts. The rework quality on

this 450A is way beyond dismal. Very close to the worst

workmanship I've seen in a very long time.

|

|

Bias Cell Installed in Holder |

I couldn't find a suitable dog-bone 1K 1W resistor in the

style needed so I took a JAN 1K 1W CC and painted it in the BED

code but with a band in place of the dot. There are a few of

this style original resistor in the receiver so it does match.

I identified all of the polyfilms I'll need for the capacitor

replacements. Seventeen capacitor are needed. I'm short five

.05uf caps but I'll look in the shop tomorrow and should be able

to find the amount needed. These will be painted and then the

value written with a paint pen. While they won't look

"original," they won't look like modern polyfilms either.

The Bias Cell -

The 1st AF Amplifier grid is biased using a "plug-in" cell. The

cell holder isn't wired (disconnected sometime in the past) but the old cell is still installed. A

modern Energizer #357 hearing aid battery or some similar type

of small cell will fit into the cell holder. When wired into the

circuit, then about -1.5vdc would be provided as the 1st AF

Amplifier grid bias. Bias requirements are extremely low-current

so cells will last for its shelf life. It's also possible to

change the 1st AF Amp to a cathode bias set-up using a resistor

and bypass capacitor to provide the -1.5 grid bias by elevating

the cathode to +1.5vdc and then grounding the 1meg grid resistor

in the circuit,...but for testing performance, I'll keep the

battery-cell grid bias at this time.

Using an Energizer #357 happened to be pretty easy since

there was a cell holder that was still present. Of course, the

modern cells are much smaller but by using .25" diameter brass

stand off that was about .312" tall as a conductive spacer, the

#357 was secure in the holder and did apply -1.5vdc to the grid

of the 6Q7 triode 1st AF Amplifier. I'm going to look through

my stand offs and come up with a brass one that's .375" diameter

that will fit into the cup better and I'll use a height that

allows the #357 cell to set "square." See next photo

down under the chassis and note the better fit of the bias cell

with a proper standoff. |

| Another Delay -

June 13, 2024 - I can't believe that I couldn't

come up with five .05uf polyfilm capacitors around here. Well, I did find

lots of .05uf caps but they were either Orange Drops, NOS molded

paper caps or weird looking types - no yellow polyfilms with

axial leads. So, I went ahead and ordered all of the values

needed for this Howard (and also for the Hallicrafters SX-9

and 5-T that are up next for a rebuild.)

June 17, 2024

- The polycaps arrived today. These are MET brand that I've

never used before. They are much smaller than the IC brand

(Illinois Capacitors) or

other yellow jacket polycaps. Although I have to use the .05uf

and .002uf METs, I'm using the IC brand for the .1uf, the .25uf

and the .02uf caps. I WON'T be ordering METs next time but will

pay more for the IC brand polycaps. It's a "size" thing,...

the METs function fine.

On painting the polyfilms,...I tried a few colors, like dark

red, dark gray, dark brown but I settled on Raw Sienna which is

a light brown color. Using Artist's Acrylic paint will result in

a flat finish to the capacitor

that looks a lot like paper. Also, this color

looks very close to the original capacitor shell color and, except

for physical size, results in a "yellow jacket" almost looking convincing

like an original

paper capacitor. As to capacitor value markings,...through

experimentation, I've found that the least amount of writing

looks

the most original. More markings, like "outside foil" bands or

voltage ratings usually lead to the writing looking quite bad. Simple

is best because it results in the best consistency of

number appearance. I just marked the value and that was all.

At least the painted caps shouldn't standout too much as

replacements. I installed seven of the painted polycaps starting

on the IF side of the chassis. The acrylic paint doesn't change

the capacitor value or affect its performance,...it's all about

cosmetics.

June 18, 2024 - All capacitors installed in

the IF, Det/AVC and Audio stages. Five caps left,...two in the

RF front end, one for the BFO, one on the Candohm and one on the

AC line. Double checking the resistor installation and the

wiring as I progress through the capacitor replacement job. |

Howard 450A

chassis after rebuild. The color I painted the polyfilm caps is

Raw Sienna - a very good color that results in the caps looking sort of

vintage. The electrolytic capacitors were painted maroon so they

wouldn't be too obvious either. As expected, the 2.5K 6W

resistor installed on the Candohm is barely visible. |

|

A close-up of the power supply

section of the 450A showing the bottom of the W-G replacement power

transformer and the HRO-60 audio output transformer. I don't

know why the HRO-60 audio transformer is MFP coated, normally

they aren't. This transformer was in a box of HRO-60 spare parts

I was given and had been marked "HRO-60" and it does check-out

as that. Works great! |

June 19, 2024

- Three electrolytic filter capacitors are required to replace the

single 8uf and the dual 8uf capacitors.

I'm not going to remove the can filters but they will be

disconnected. Under the chassis I'll install three 10uf 450vdc for

the 8uf electrolytic capacitors. Modern electrolytics are very familiar-looking so I've painted the

replacements maroon so they won't "stand-out" as much.

Finished all of the polyfilm capacitor installation. I installed

one of the 10uf electrolytics. One lead on the filter choke

needed an extension added. All that remains will be to install

to two remaining 10uf electrolytics and then install a suitable

AC power cord (I found a vintage cord with a molded plug that

should look original.) June

20, 2024 - Installed the two remaining

electrolytic capacitors. Installed the vintage AC power cord.

Tested the tubes and found that one of the 6V6 tubes was much

lower gm that the other 6V6. The low 6V6 was just barely above

minimum acceptable, so it was replaced. One of the 6J7 tubes

tested at minimum acceptable so it was replaced. All other tubes

tested good. Found some replacement tubes for the 6V6 and the

6J7(replaced with a 6J7GT.) Cleaned tube sockets with DeOxit and

installed the tubes.

AC Applied - To power up the 450A, I monitored the input

voltage

to the Candohm resistor which is also the 6V6 plate voltage. I

slowly ramped up the Variac and stopped at 90vac input. The

receiver took

a while warming up (at that low of an AC input voltage) but I finally heard some noise in the loudspeaker. The 6V6 plate

voltage was +210vdc. I increased the AC input voltage to 115vac

and the 6V6 plate voltage was at +255vdc which was perfect. I

had the receiver on the AM-BC band with a ten foot long test

antenna. I adjusted the RF Gain and AF Gain controls and tuned

(no dial mounted yet) by looking at the tuning condenser mesh.

Several of the Reno AM-BC stations "pounded in" quite strong.

KKOH 780kc had the R-meter about mid-scale. Lots audio power

available. Tried a few other stations and all sounded fine. I

switched the AVC on and off and some distortion could be heard

with the AVC off which isn't unexpected. So far, the 450A seems

to be functioning fine but I'll have to install the glass dial

and points before I do any alignment. Also, I have to do further