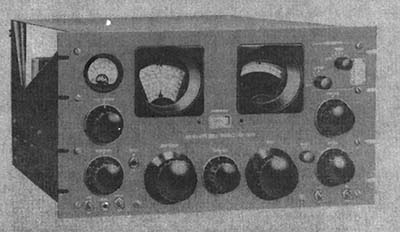

| The SP-600's ability to perform well as a vintage ham

receiver is really a subjective judgment of the ham operator. The SP-600

is rarely encountered as "THE ham station receiver" and most

of the time, if it's even present in a vintage ham station, it will be

in the background, maybe installed in a rack of seldom used equipment.

When everything is working correctly on a SP-600, it's an impressive

performer and would a very usable receiver that would be a pleasure to

operate. So, why isn't it a popular choice for the vintage station receiver? Hmmm,...a

good question. Here are the SP-600's

good points,...and a few of the not-so-good points.

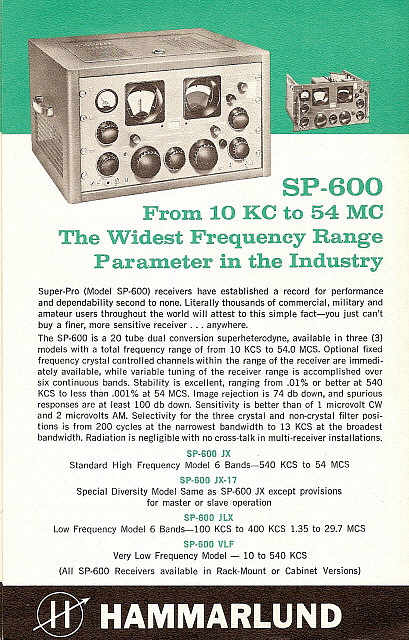

Sensitivity - The SP-600

can be a very sensitive receiver. It's specs were 2uv in AM and 0.75uv

in CW for a signal to noise ratio of 10db. It's sensitivity above 20mc

all the way up to 50mc is impressive, especially for a receiver that was

designed in the post-WWII, late-forties era. To achieve the rated

sensitivity however, the receiver will require a full rebuild, NOS or

equivalent tubes and MOST IMPORTANTLY,...an accurate IF/RF alignment

using laboratory-quality equipment. Additionally, a resonant or matched

antenna for the tuned frequency is necessary to achieve the highest

level of sensitivity. When these criteria are met, the SP-600 will hear

just about anything on the air, with propagation conditions, QRM or QRN

being the only limitations.

Selectivity - The selectivity is very good at the 3kc position for SSB and CW

signals. AM signals can have the bandwidth expanded to 8kc and if the

station is very strong, try 13kc for the ultimate in wide bandwidth

audio response. I find that the 3kc bandwidth is actually good for

strong AM signals since the upper audio frequency attenuation tends to

enhance the bass response a little resulting in a mellow sounding audio.

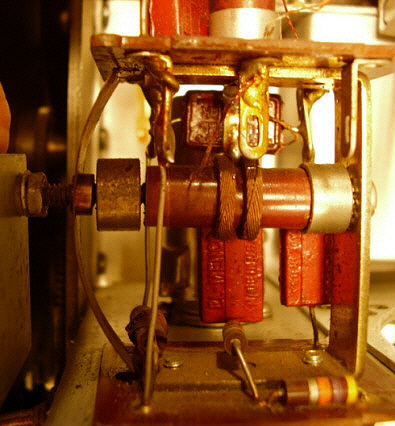

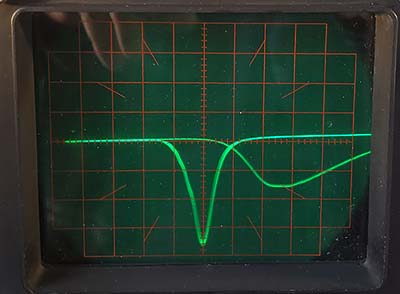

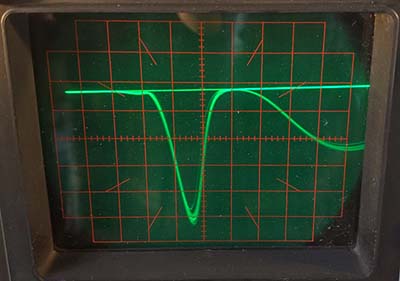

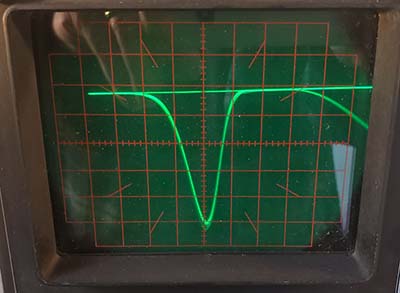

A sweep IF alignment will really help in getting the proper relationship

between the 3kc, 8kc and 13kc bandwidths. With a sweep IF alignment,

strong AM stations sound very nice in the 13kc bandwidth.

The Crystal Filter has it critics but I find that it

works very well on CW but even SSB or AM can benefit from its use when

adjacent frequency interference is a problem. Accurate alignment of the

crystal filter is crucial for its proper operation and the

correct alignment depends on accurately setting the PHASING knob to

agree with the dual-stator/single rotor PHASING condenser. When set up

correctly with a full IF alignment, the Crystal Filter works just like

one would expect. The <> is the maximum selectivity and heterodyne

action takes place around and near the <>.

Dial Resolution Vagueness and Rapid

Tuning

- Many users feel that the tuning dial's

vague readout accuracy is the main disadvantage to using the

SP-600 receiver and

generally you'll find these critics comparing the SP-600 to the R-390A.

These two receiver's utilize design approaches that couldn't be more

diverse - not to mention that the R-390A cost was at least two and a

half times

that of the SP-600. The SP-600 covers large slices of the spectrum in

each tuning range. You just couldn't get one kilocycle accuracy when

each tuning range covered several megacycles using a variable-C type of

tuning. Collins utilized a

precision PTO (permeability-tuned oscillator) with a tuning range of just 1000kc in ten turns. That was mixed with a

multiple-crystal-controlled oscillator and variably tuned IFs that resulted in double or

triple conversion and 1kc or better tuning accuracy. It

was expensive to build the R-390A and it could be difficult to maintain. The SP-600

was easy to maintain, although parts of it are difficult to disassemble,

it's easy to work on (sort of) and, when in use, it allowed rapid coverage of wide areas of the spectrum

- something necessary for certain kinds of surveillance. This rapid

tuning though does make tuning in some stations difficult, especially at

the higher frequencies. The

logging scale was provided to allow a means of accurate resetability and

its use will really help in finding net frequencies for monitoring. Once

you've found the net, make a note of the logging scale reading and

you'll always be able to retune right to the correct frequency.

Drifting - What can you expect from Hammarlund? The

typical SP-600 doesn't drift excessively after a 30 minute warm-up

(it might never stop drifting but it's a minimal drift after 30 minutes.) As

mentioned elsewhere, the Crystal Controlled Switchable Oscillator - the

"X" option - is rarely used. It requires specific crystals for the

desired tuned frequency and then you still have to tune the receiver to

the desired frequency so that the RF stages and the Mixer are in tune.

Audio Reproduction -

Another often heard complaint is the SP-600 audio. An individual's

impression of the SP-600's audio quality is obviously a subjective

judgment. Some users find the audio to be standard "communications

grade" with limited bass response while others listeners find

the audio to sound "high fidelity." The stock bass response is rolled

off so that the -3db point is at about 125hz resulting in a moderate

bass at best. Use 3kc bandwidth for upper audio attenuation to enhance

the bass somewhat. Be sure to match the 600 ohm output for the best

audio reproduction and use a large speaker in a good enclosure. The

audio has a lot of highs when the bandwidth is in the 13kc position and

this tends to really de-emphasize the bass response but again, it

depends on the loudspeaker being used. A lot of the listening experience is dependent on the

loudspeaker location. If the loudspeaker is directly in front of you and

only about two feet away you'll be hearing the high frequency audio

overpowering the bass response. Try locating the loudspeaker about ten

feet away. It will require the AF Gain to be somewhat higher but the

loudspeaker's distance tends to roll-off the audio highs and, since low

frequency audio has more power, the bass response is improved. The

advanced AF Gain also tends to improve bass response.

SSB Reception Issues -

The calibrated BFO can be very accurate and very handy for

SSB. You do have the capability of selecting upper or lower sideband by

which side of "0" you set the BFO. BFO-drift is just about

non-existent after about a 30 minute warm-up. To set the BFO to the correct sideband,

first set the BFO to "0" and then tune in the SSB station to "zero beat" or where the audio sounds

"muffled and bassy" - then, by adjusting just the BFO to one side or the

other of "0," the audio will clear up and sound normal. Whichever side

that is will be the correct setting for whatever sideband that station

is using and more than likely for all the SSB ham stations on that

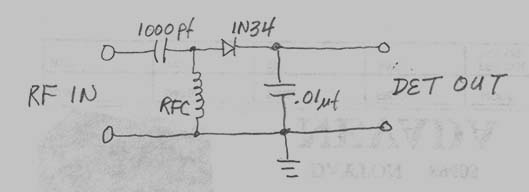

particular band. The SP-600 will provide excellent SSB audio. And you

don't need a Product Detector or a CV-591-type of external SSB IF unit

either. Good SSB demodulation requires that the detector has the proper

ratio of BFO injection to the incoming signal level. Best audio will

require that the AVC is in the OFF position and that the RF gain control

used to set the correct ratio. Turn the AF gain up to 6 or 7. Turn the

RF gain to a level where the incoming received background noise is

moderate - usually about 7 or 8. Selectivity should be on 3kc. With an SSB

be signal tuned in, reduce the RF gain if the audio sounds distorted.

At the proper RF gain setting, SSB signals sound fine on the SP-600.

The disadvantage is that every signal has a different strength and the RF

gain usually has to be adjusted each time. With "one on one" QSOs,

it's usually not a problem but Net Operations, with many different

stations "checking in," can be somewhat frustrating. You can operate

with the AVC on to limit the maximum sensitivity (with the RF gain set

to about 7) but strong SSB stations might still distort. Most

versions of the SP-600 provide an adjustable BFO Injection adjustment

located on the rear apron of the receiver. Be aware that when the BFO

Injection is adjusted to maximum, the BFO Buffer tube's cathode is

grounded and the tube will tend to run somewhat hotter than usual. If

the BFO output is typical for a good condition SP-600, ample BFO

injection for SSB will be with the Injection set to about 50%. A very low-level

of BFO injection was provided for CW signals and prevented "masking" of

very weak CW signals.

Fixed Antenna Input Impedance

- By using the ham station antenna you will be providing

the SP-600 with a matched antenna that will allow it to perform at its

best. Many casual listeners using unmatched end-fed wires may be

disappointed at the SP-600s performance, especially when considering the

high noise levels experienced with end-fed wires. The SP-600 was

designed to operate with a matched antenna and this set up will give the

best performance results. There isn't any sort of Antenna Trimmer

control provided because Hammarlund expected the end-user to provide a

matched antenna (dipole usually) with approximately 100 ohms impedance (50Z or 75Z will

also work

fine.)

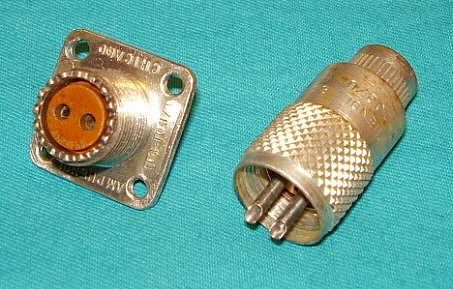

Remote Standby Relay - Most SP-600 versions will have a RELAY

socket that looks like an AC receptacle. This parallels the SEND-REC

switch and allows the receiver to be put into stand-by remotely. This

can be done with the auxiliary contacts on a Dow-Key type relay and it

makes using the SP-600 as the station receiver very practical. Be sure

to leave the SEND-REC switch in the SEND position when using the remote

stand-by function. An exception to this RELAY socket is the popular

SP-600 JX-17, which, since it was for diversity reception, does not

include a remote standby option.

|