|

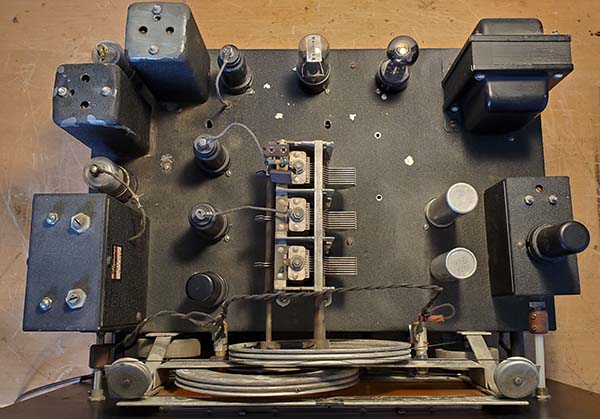

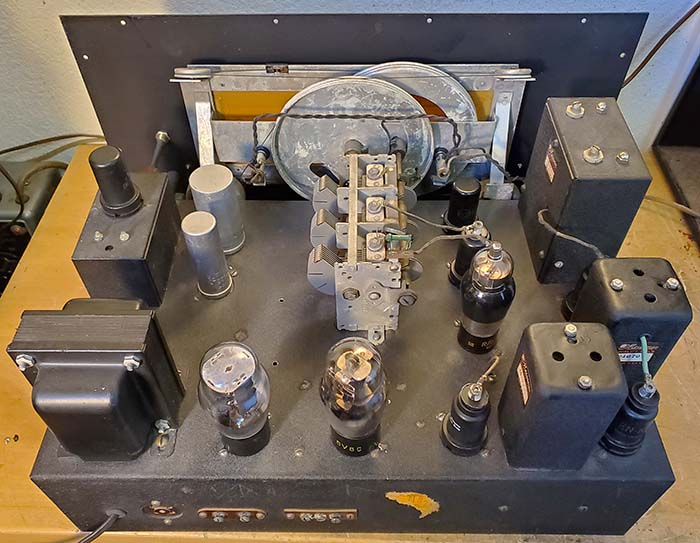

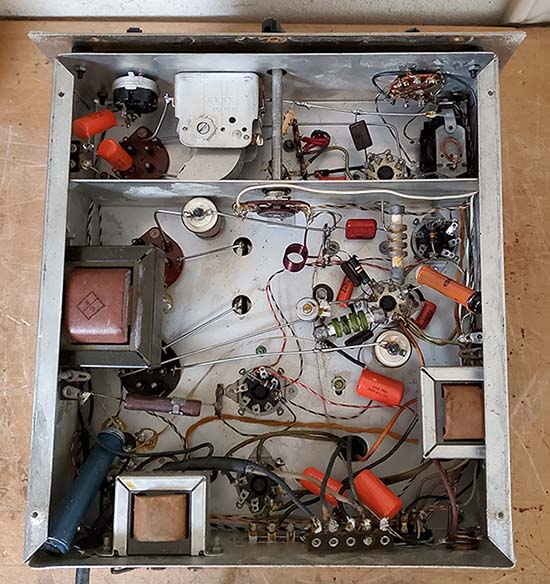

Band Switch/RF Coil

Assembly Removal - In order to correct the problems involving the RF

amplifier, the Mixer and the LO circuitry, I'm going to have to remove

the Band-Switch/RF Coils assembly. Most of the front-end circuitry is covered up

and inaccessible when the Band Switch/RF Coils assembly is installed. Removal isn't too

involved but, naturally, when the hamster-rework was performed, this

assembly was left in place. This resulted in some of the accessible

parts being replaced with wrong value parts that were sloppily

installed. But, the remaining capacitors (the inaccessible ones) in the

front end appear to be originals. Inspection is required and that will

involve dismounting the Band Switch/RF Coils assembly. Removal of the assembly has six braided wires from the tuning condenser, the

two antenna input wires (Ant and Dipole,) B+ wire, two wires to the RF

amplifier tube socket, a replacement JAN 27K 2W resistor to the LO tube (incorrect

value, of course, should be a 10K BED resistor,) four ground wires

that are soldered to the chassis,...plus two screws and the switch shaft

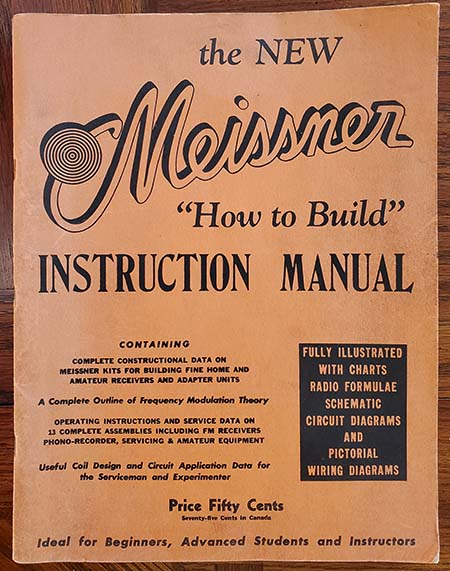

bushing nut and lock washer. Although, the wires are shown on the schematic and

shown in detail in the Meissner booklet "How to Build," I made another sketch of just the front-end

connections to ease the reinstallation. With the front-end dismounted

and out of the chassis, now it's very easy to see what needs to be done

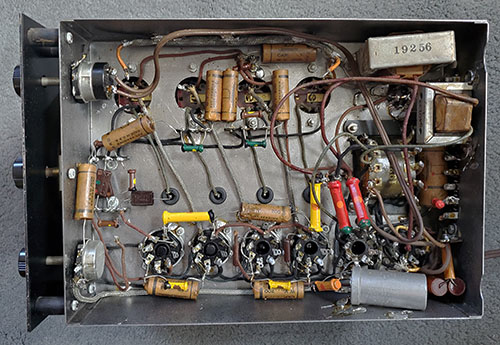

here first. Replacement

Capacitors - The original paper capacitors were Meissner

brand so almost all of the original shells are long-gone. I checked to

make sure I had all of the required capacitors in polyfilm types (yellow

jackets) and I did. Initially, I thought about just painting the yellow

jackets and not bothering with the shell stuffing since I'd have to find

23 matching shells. But, the more I thought about it,...this Scout is so

complete and not physically modified and it will have an original

circuit when I'm through with the rebuild so it should probably look as

authentic as possible. It would

be a shame to NOT do the capacitor stuffing (an OCD moment.) I checked the junk box

C-shells and I have the necessary (14)-.05µf, (8)-.01µf and (1)-.005µf

(but this shell is going to be marked .006µf.) Wires

- The written assembly instructions indicate that the wire supplied had

rubber insulation but the wire in this Scout is solid 22ga wire with

cloth insulation. The color codes do match the assembly drawing and

schematic. These definitely are the original wires but apparently

sometime during the Traffic Scout kit availability the wire type was

changed to rubber insulation. Actually, the cloth insulation survives

time and environmental conditions much better than rubber insulation

that tends to dry-out, crack and fall off of the wire. Resistors - The

original resistors are B.E.D. code and are the type with the wire-wrap

around each end for the leads. I have lots of these types for

replacements for the originals that have drifted and for the new-types

that are installed. The dissipation shown on the schematic and assembly

drawing seems low for the physical size of the resistors but I think

that's just the operating temperature specs of the time. I used as close

as possible for the physical size for the vintage resistors.

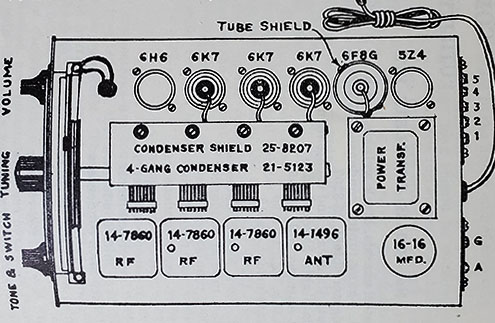

Documentation Conflict,...or is it?

- This is minor,...the schematic for the Traffic Master Tuning Unit shows that the LO plate voltage bypass

capacitor is a .05µf 400vdc paper cap. The schematic for the Traffic

Scout receiver shows the same capacitor as .01µf 400vdc paper cap. I can't

reference the original capacitor since it has been replaced with a

molded-type of capacitor but,...the replacement is a .01µf cap. So,

which value is correct? The Traffic Master

"Tuning Unit" is a complete chassis assembly with tubes, tuning condenser

and the Band Switch/RF coils assembly. The Traffic Scout, on the other hand,

is only the Band Switch/RF Coils assembly mounted under the receiver

chassis with the tubes and tuning condenser mounting on top the main

receiver chassis. I suspect the Scout schematic

is probably correct and the value was originally .01µf (there was also a

resistor value change and this is because the Traffic Master used a

regulated +150vdc B+ in the LO screen and plate and the Traffic Scout

uses an unregulated +200vdc B+.) As mentioned, this component is only a

B+ bypass, so its value isn't critical.

|

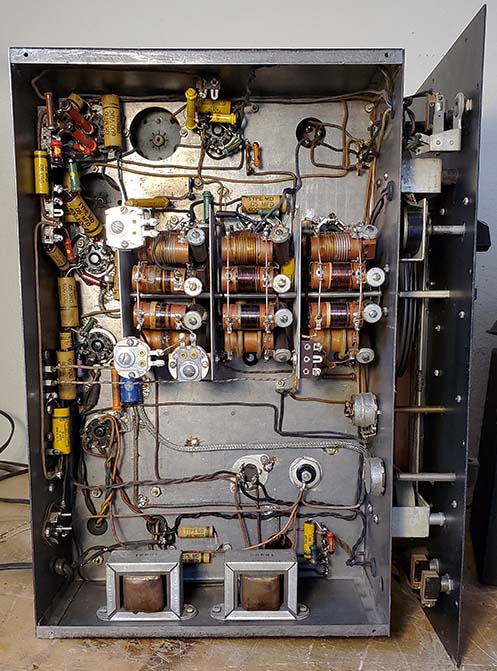

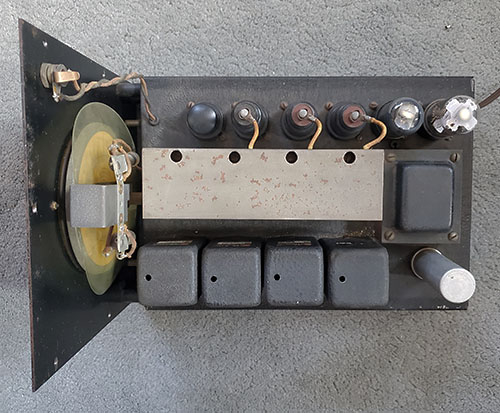

Meissner Traffic Scout - Band

Switch/RF Coils Assembly

It's easy to see that the BC band coils are at

the left side as shown here and a clockwise rotation of the band

switch connects the progressively higher frequency coils going

clockwise. Only Bands 1, 2 and 3 have LO padders (the three

lowest frequency coverage bands.) |