|

The Creation of Radio

Corporation of America, Superheterodyne Licensing and Gilfillan Bros., Inc.

In 1919, GE was working on a sale of

their important wireless patents, including the Alexanderson

Alternator, to the British Marconi Company (known as Marconi's Wireless Telegraph

Company Ltd. in England) When the U.S. Navy "got wind" of this intended

sale, they were livid. Especially since the information had come to them through

"ordinary trade channels." The Navy had just spent the past

few years (WWI) securing and protecting US wireless stations along with

protecting the transatlantic communication cables which were the sole

communications between the US and Britain during WWI*. Developing

reliable U.S. maritime radio communications was a top priority for the Navy and, here was GE, ready to sell

their major wireless licenses and patents to the Brits.

The Navy sent

their top brass, headed by Commander Stanford Hooper and Rear-Admiral William

H.G. Bullard, to GE to persuade them to not

sell USA wireless patents to a foreign nation, even if they were a

longtime ally. The Navy wanted GE to create a "radio company" that would

"do everything in radio." That would include

building equipment for the Navy, operating and maintaining

commercial wireless stations, building and selling radios and parts and, generally, be the exclusive manufacturer of

"all things radio"

for the United States and

especially for the

Navy.

Admiral Bullard, who was the newly appointed Director of

Naval Communications for the Navy Department, was able to convince GE's chief console and

vice-president Owen Young that this "radio company" was not only a patriotic

response to British Marconi's intent to purchase the USA wireless

technology but that such a "radio company" could be a very

lucrative arrangement for the GE. Owen Young convinced the other GE board members

that the sale to British Marconi should be

cancelled. In October 1919, GE set up the preliminary version of "the Radio Corporation"

using just their own assets. This didn't seem to be enough since no

manufacturing facilities were included, especially for

the type of company

the Navy (and now GE) had in mind.

GE knew that the American Marconi Company had long been concerned

that the majority of their ownership was in British hands. Ed Nally Jr, vice-president of American Marconi and A. G. Davis (of GE)

were sent to Britain to first, cancel the GE-British Marconi deal and to

second,

negotiate a new deal to buy American Marconi. Davis and Nally were

successful and were able to have GE buy the entire American Marconi

company, including their manufacturing plant in Adelaide, New Jersey. >>>

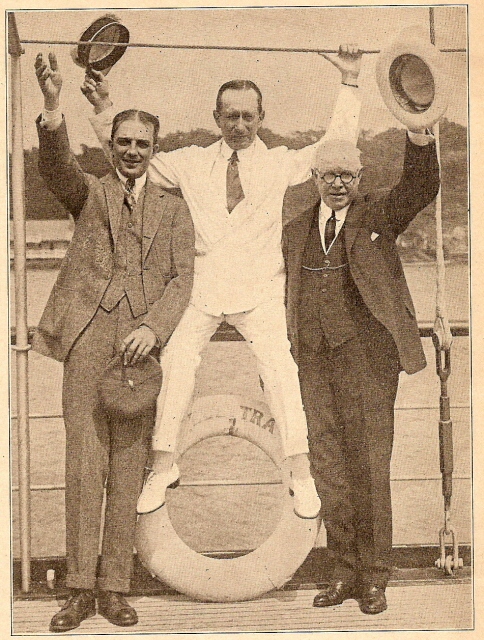

photo right:

Owen Young (left) vice

president of

GE and board member of RCA,

Guglielmo Marconi (center) of

Marconi's Wireless Telegraph Company Ltd. and

Ed Nally Jr.

(right) the first president of RCA. Aboard Marconi's yacht, Elettra, in 1922.

Photo from: "Radio Journal"

Sept, 1922

|

|

|

|

>>> In November 1919, RCA was

officially formed and announced to the wireless world. Ed Nally Jr. was

the new president of RCA with Owen Young becoming a powerful RCA board

member. The RCA formation seemed set to launch the "Radio Corporation"

into the wireless business, but, at the last moment, General Electric

decided that too much strategic manufacturing power would be in the hands of RCA and that GE would

have little control of RCA operations. To have and maintain control over

RCA, GE retained the American Marconi plant for themselves and

essentially took all of RCA's ability to function as a manufacturer away

from them. RCA became what was essentially a sales agent for all of the

members of the "Radio Group," an unofficial name for the

patent-sharing and cross-licensed radio companies headed by GE. These

companies were RCA, AT&T, United Fruit Company and Westinghouse. RCA

sold radios and parts built by these companies (but, in most cases, with the RCA name on

them) through most of the twenties.

However, many of the old American Marconi

responsibilities became new RCA duties. The old Marconi Institute for

training radiomen became the RCA Institute performing the same function. Many of the commercial

wireless stations had to be maintained by RCA and, in some cases,

operated by RCA. This was how RCA operated

through the early-1920s. However, RCA was determined to become more than

just a sales-agent for the Radio Group and throughout the 1920s was

slowly purchasing various patents, developing the radio business and

growing into what the Navy had first envisioned. It would take a decade

of time and the

Federal Government to make it happen, though.

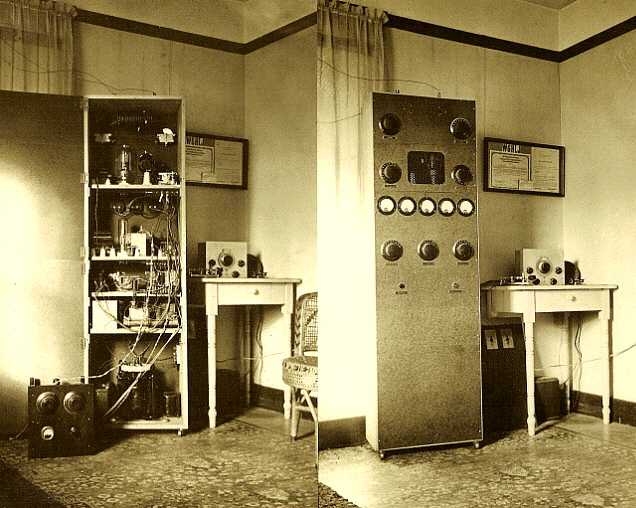

photo left:

Rear-Admiral William H.G. Bullard was Director of Communications for the

Navy Department. Bullard was instrumental in convincing GE to

form RCA.

Photo from: "Keeping the Stars and Stripes in the Ether"

- "Radio Broadcast" - June,

1922

* During WWI, Britain had laws in-place that prevented using

wireless for wartime transatlantic communications therefore all of these

important

communications between Britain and the US went by wire telegraph over the

transatlantic cable. The US Navy feared German submarines could have the

ability to destroy

these cables and seriously delay wartime communications. Thus the Navy

spent considerable effort to defend these cables against attack.

|

|

RCA during the 1920s

- Through most of the 1920s, almost all consumer-entertainment radio

manufacturing business for RCA was controlled by GE and to a certain

extent by Westinghouse. These two companies continued to build all of

the consumer radios that RCA sold during the twenties. RCA, though,

continued to buy other radio interests, radio patents and create other

businesses related to radio. In 1923, RCA bought Wireless Specialty

Apparatus Company from the United Fruit Company. This company

specialized in marine radio gear and continued to build that gear for

RCA to sell. Since this wasn't infringing

on the lucrative broadcast radio market, the Radio Group (minus United

Fruit Co.) didn't object. In 1925, RCA

bought a New York radio station and from that created the first network

broadcasting entity, National Broadcasting Company, or NBC.

In 1927, RCA was able to purchase the TRF patent (not the Neutrodyne TRF,...that belonged to Hazeltine and the Independent Radio Manufacturers.)

Additionally in 1927, RCA purchased Independent Wireless Co. and

combined it with Wireless Specialty Apparatus and created Radiomarine

Corporation of America, which became a subsidiary of RCA handling all of

the marine radio business.

In 1928, RCA got involved in the movie industry as part of RKO. RCA's

first president Ed Nally Jr. was president from November 1919 up to late-1922, at

which time he retired. Looking at the photo above (taken aboard

Marconi's yacht) one would think that Nally died but he lived on quite a

long time after retiring from RCA and died well-into his nineties (in the early

1950s).

RCA's second

president was a retired military man, James G. Harbord. He ran RCA

from late-1922 up until he retired in January 1930. Harbord viewed radio as a

powerful medium that was destined to grow and become an essential

resource for the business world and for daily human life. Most of his

"radio predictions" did become reality.

|

David Sarnoff

becomes RCA President - January 1930

Harbord's retirement was to allow general manager David

Sarnoff, age 39, to become president of RCA. David Sarnoff had

been with American Marconi before it became RCA and had worked

his way up through the company. He was head of RCA up into the

1960s. Sarnoff is usually credited with starting NBC and with

developing the idea of broadcasting via networks of radio

stations.

Photo left shows James Harbord (left) and David Sarnoff (right)

apparently depicting Harbord handing Sarnoff the "RCA reins."

photo from: www.sweetliberty.com |

|

RCA-Victor

Beginnings and the

1930 Anti-Trust Suit

- Around 1927, RCA was approached by the owners of the Victor Talking Machine Company. It

seemed that VTM Co's CEO Eldridge Johnson had been in declining health

and had sold his Victor interests to a banking syndicate in 1926. The

bankers now needed someone to run the failing Victor company, or to buy

it outright. RCA initially took over operation of VTM Co

manufacturing and began to incorporate GE or Westinghouse-built radios into elaborate combinations with

Victor phonographs. VTM Co. under Eldridge Johnson had viewed radio as a

competitor but now Victor created a few radios using the RCA held TRF

patent. These became the Victor Microsynchronous Radios found in many VTM

Radiola-Electrolas. These machines were moderately successful but RCA

really needed to "own" VTM Co to expand and develop their radio

business and become independent of GE. To purchase VTM Co was going to

require a substantial amount of cash - $15 million along with an

additional $15 million to convert Victor, essentially an old "victrola" manufacturer, into a modern, up-to-date radio

manufacturing company. Amazingly, RCA made a deal with General

Electric and Westinghouse to have them supply the needed cash "up front" in

trade for RCA stock to be transferred later down the road. Sarnoff was

running RCA at this time because James Harbord had taken a leave-of-absence

through most of 1928 to campaign for Herbert Hoover in the presidential elections of 1928.

Harbord retired in January 1930 to allow 39 year old David Sarnoff to

then become

president of RCA. The Victor factory in Camden,

New Jersey was converted to a radio factory by late-1929. RCA created a couple of

small companies, "Radio-Victor" and "Audio-Vision Appliance" to operate VTM

Co. This cumbersome arrangement was quickly changed to one company

called "The Victor Division of Radio Corporation of America"

better known as "RCA-Victor." Almost immediately, the federal government

stepped in and served up an Anti-trust suit against everyone that was

left in the old "Radio Group." At the time the suit was filed, that included GE, Westinghouse, RCA

and AT&T. The government singled-out GE and Westinghouse for punishment.

RCA was singled-out for rewards.

The settlement turned literally

everything "radio" over to RCA. The superheterodyne patent that had been

owned by Westinghouse was now RCA's. Additionally, all of RCA's debt to

GE and Westinghouse (involving the VTM Co. deal) was cancelled. Also, GE and Westinghouse couldn't

compete in radio with RCA for two years (they actually had to buy

RCA-built radio chassis to install in their own cabinetry until 1933.) RCA came out of the settlement

not powerful in radio,...they were

OMNIPOTENT in radio. They owned or controlled almost all aspects

of radio. All "legal" radio manufacturing in the US required a license from RCA. In essence, the government had stepped in and re-created RCA

into the "all-powerful" entity that the U.S. Navy had wanted eleven years earlier. |

|

Superheterodyne

Licensing, Sub-contractors

and the Gilfillan Bros.,Inc.

The anti-trust settlement also stipulated that RCA would now have to license other

manufacturers to build superhets. Every major radio company had to have the RCA

Superheterodyne License in order to remain competitive even though there were

royalties, certain rules to be followed and other conditions with having the license. By mid-1930,

most of the major radio companies had their superhet licenses and were

designing their new models for the 1931 sales year (Fall 1930 to Spring

1931.) However, some of the conditions required that the manufacturers had to produce radio chassis in sufficient quantity and of high quality in order

to qualify for the RCA license. This left many small companies unable to qualify for the

license due to their limited market, small overhead and the expenses involved in producing

high quantity and high quality chassis.

Fortunately, for the small radio companies, there

was a option in the RCA license rules and conditions that allowed a license-holding

company to build chassis for other un-licensed companies. Gilfillan Bros., Inc. in Los

Angeles, California had the only RCA Superheterodyne license in the West

(exclusive license-holder for 11 Western states.) This arrangement was the

result of a 1928 "face to

face" confrontation between S. W. Gilfillan and David Sarnoff, (who admired

Gilfillan's determination.) At the time of the Sarnoff-Gilfillan meeting, James

G. Harbord (RCA President from 1922 to 1930) had taken a leave of absence to

campaign for presidential-candidate Herbert Hoover and that left general manager, David Sarnoff, in

charge. The Sarnoff-Gilfillan arrangement was the offer of exclusive RCA

licenses in exchange for closing all Gilfillan operations not in the

Western States. Specifically, the Gilfillan plants in Kansas City and New York

City were the

apparent targets of the agreement. At the time, this licensing was mainly for TRF

circuitry but, in 1930, the superheterodyne was added to Gilfillan's exclusive

licensing. >>>

|

>>> Gilfillan allowed

subcontractors to build their own chassis on the second floor of the Gilfillan

plant. This included Los Angeles companies such as Patterson, Breting, Jackson-Bell,

Packard-Bell, Kemper and Pierson-Delane along with dozens of other smaller companies,

all in the Los

Angeles area. During the early 1930s, the sub-contractor policy was not very strict and the

complete radio

didn't have to be totally assembled by the licensed company. Some

sub-contractors only had the radio chassis and cabinets built and then completed assembly themselves. The subcontractor was

protected because he was building the radio using a chassis supplied by the licensee

and the building process was supervised by the licensee. Some companies (including Gilfillan) allowed sub-licensed

companies to supply their own assemblers, set up their own production lines,

utilizing plant stock and tools, using plant

floor space at the license holder's company.

The sub-licensing policies

allowed many small radio companies the start-up operations because the major

expense, that is, purchasing real estate, building a factory, purchasing equipment and

production stock expenditures were

eliminated. This left the new radio company/sub-contractor to only have to hire

personnel and have a good design to build. During the Depression, this really

was the only option for a small company to produce quality radios, be able to

sell those radios and profit from that business. Also, those profits were shared

by the licensed

company (5% to Gilfillan which they split with RCA.) The subcontractor licensing

allowed everyone involved to profit during the difficult economic times of the 1930s.

There was the added benefit to the would-be purchasers that, because the

subcontractor radio company's overhead was so low, the radio products could be

sold for a much lower price and still net a profit for that subcontractor and

for Gilfillan. On average, Breting and Patterson receivers sold about 40% to 50%

less than a comparable National or Hammarlund product and about 30% to 40% less

than a comparable Hallicrafters product.

In 1940, RCA decided

that there was not enough quality control on the chassis produced for the smaller

companies by the license holding companies and began to stop allowing the sub-licensing

option. The RCA license structure was also changed at that time to allow most smaller

companies to obtain their licenses direct from RCA. However, Patterson had quit

the radio business in 1939 and his major West Coast competition, Breting Radio

Manufacturing, quit the radio business in 1940.

|

|