|

Single preselection is used with a converter tube circuit and

two 560kc IF amplifiers. Audio output is transformer coupled and

is intended for a Hi-Z headset (5K output impedance.) All

voltages to operate the R1155 are supplied through the T1154

transmitter. An interconnecting cable runs from the transmitter

to the right-most Jones plug, P1, on the lower front panel of the

receiver. The left-most of the Jones plugs is P3 which is for the loop

antenna connection (there's a vari-C trimmer and optional fixed

C inside this plug) and the center plug is P2 for the Visual

Indicator connection (R-L meter.) All

inputs and outputs to and from the R1155 are routed through

these three Jones connectors. Voltages required are +6vdc tube

heaters (parallel connection) and to compensate for 12vdc

systems an external Type 47 Resistance Unit was installed or for 24vdc

systems a Type 52 or 52A Resistance Unit was installed. The

+230vdc B+ and a negative bias of around -30vdc were provided

through the T1154 by one dynamotor-type system power unit

(called a "rotary transformer" in the manual.) The "VOLUME"

control operates as a sensitivity control when the AVC is off (furthest

CCW position on Master Switch MS) and as an AF Gain control when AVC is

selected. The BFO is turned on when HET is switched on. The small panel

hole above the dial next to the METER AMPLITUDE control allows

adjusting the HET oscillator frequency. The small panel hole to

the right of the MS allows adjusting the loop

antenna trimmer. All of the controls along the upper

section of the front panel are for the direction finding

operation. Receiver only controls are Band Change, MS, HET

on/off, Volume and Tuning. The R1155 worked in conjunction with

several auxiliary pieces of equipment that included the Visual

Indicator Type 1, the Loop Antenna compass, the Antenna Switching

panel Type J, Type 192 Mic/Tel panel. Sometimes the setup included two

Visual Indicators at each station (radioman and navigator.) Up

to three antennas could be connected to the R1155, the loop

antenna, the sense antenna and the trailing wire antenna,

depending on the service the receiver was going to perform

(communication or navigation) and on what frequency the receiver

was operating.

The "A" in R1155A indicates that MW filters are installed to

eliminate broadcasting interference at the IF (560kc.) "B"

indicated the receiver had additional filters for operating near

radar systems. There were several designated internal options

available running up to a "N" version. Most variations indicate

SW (radar filters) and/or MW (AM-BC filters) internal filtering,

construction material (aluminum or steel) and in some cases end use. Some

versions were for mobile-land use, some were used in ground

schools and there were two types for

marine use (air-sea search-rescue aircraft.) There were several

types of 230vac 50cps power supplies available for land use.

Some R1155 receivers were built on steel

chassis with steel front panels and steel shielding. These were

undoubtedly for ground

use or installations other than airborne - the steel receivers

are noticeably much heavier than the aluminum receivers. Most

receiver cabinets have five cork panels glued to the inside

recessed areas. The rear inside cork panel has the vacuum tube

locations and tube types shown on a glued-on paper label. |

photo above: A very original example of a R1155B receiver

with lots of "use patina."

It appears to be virtually complete and all original although

judging by the "mod plate" (modifications record - the metal tag

to the right of the band switch) this receiver has had several

"upgrades" installed over the years. "B" versions had

internal filters for operation near radar in addition to the MW

filters. Note the

six-digit serial number indicating that production quantities of

R1155 receivers was quite high. Also, note the dates on the

various tags in this receiver,...1967,...this R1155 was in use for quite a

long time after WWII. This example is fitted with the improved

two-speed tuning knob. This receiver is also fitted with the

"blocking plug" that has the "COMMUNICATION RECEIVER"

tag on the front indicating this R1155B was used in a "dual

receiver" set-up where the navigator had the DF R1155 and the

radioman had this receiver and the DF abilities couldn't be used. This receiver also has the Jones plugs

retaining strap installed.

photo from: eBay UK |

| DF

Controls - The R1155 used an external

"cross-needle" Visual Indicator meter (actually two meters

within the unit) to show

visually if the airplane was on-course. First a homing beacon station

was tuned in. Then the receiver was switched to "BALANCE" which

connected an antenna coil into the circuit and METER BALANCE was

adjusted for the two meter needles to be equally in the

"crossed" position. The receiver was then switched to VISUAL and

the loop antenna placed perpendicular with the fuselage

(athwartship) and the airplane steered toward the beacon which

showed the crossed-needles on the meter when on-course. The

pilot would deviate his course slightly and if the

crossed-needles moved off-center-downward the beacon was behind

the airplane. The pilot would turn around, the course aligned

and then any deviation moved the needles off-center-upwards,

indicating the beacon was ahead. As the airplane approached the

beacon the signal would get stronger and METER AMPLITUDE was

adjusted to keep the crossed-needles near the center of the

field. METER DEFLECTION HIGH-LOW changes the sensitivity of the

meter depending on the signal strength of the beacon.

Alternately, if a specific direction of an unknown signal was

desired, such as in a "search and rescue" operation, then the

receiver was switched to the horizontal figure-8 position (loop

antenna only) which then allows a bi-directional response to the

signal as referenced to the loop's position relative to the

airplane's fuselage and its direction of flight travel, to be

determined. With the signal tuned, the loop antenna is rotated

watching the TUNING INDICATOR (eye tube) looking for a minimum

signal which would be one of the bi-directional nulls. The loop

is then rotated +90º and the AURAL SENSE pushed to the

right, if the signal is reduced in strength then the signal's

location is toward the front of the aircraft fuselage (if the

loop and compass are set for 0º being the nose of the

aircraft.) If the signal increases

instead,

then the loop is rotated +180 degrees, the AURAL SENSE pushed to

the right again and the signal should decrease indicating the

correct signal location is in front of the aircraft

fuselage. Alternately, true

direction can

also be determined by alternately pushing AURAL SENSE both L and

R, which ever produces the lowest level signal is the correct

direction of the signal origin in relation to the aircraft

fuselage and the aircraft's course bearing. The SWITCH SPEED changes the multi-vibrator

switching rate at the modulator circuit with the combination of

the phase-shifted loop with the sense antenna. The meter drive

output and mixer circuit uses the multi-vibrator speed in

combination with the receiver detector output indicate a phase

change between the loop and sense antennas (caused by the

airplane's course versus the path of the beacon's signal) that

then drive the meters indicating right or left of the aircraft

position. The speed

settings are LOW 30hz for a voice beacon (like using

an AM-BC station as a beacon) or up (high 80hz) for a CW or

tone beacon. For more detailed DFing and navigation

information go to the "USN & USAAF Airborne Navigation

Equipment"

Part 2 of WWII Radio Communications Equipment. |

| RAF Modifications

- It's common to find complete and original R1155

receivers that are missing V1,V2 and V9. When the radioman's

receiver was paired in the airplane with a navigator's R1155, then these three

tubes were removed from the radioman's receiver. These were the three

main DF tubes and if the receiver was just to be

used as a "receiver," V1,V2 and V9 were pulled to drop the tube heater

current requirements (900ma drop, almost an amp.) The tube

heaters are wired in parallel so pulling tubes that weren't

needed wasn't a problem. Also, a dummy plug (called a "blocking

plug") was inserted for the

loop antenna cable and the Visual Indicator cable when the R1155

was just to be operated by the radioman.

Nowadays, if the missing tubes are going to be replaced, V1

and V2 are CV1099 tubes that are

inexpensive and easy

to find. V9 is a dual triode, VR102/BL63, of which the USA equivalent is the

6F8G. Audiophiles have driven the price of both the 6F8G and the

VR102/BL63 into the stratosphere. Why? Because the 6F8G is the

pre-WWII predecessor to the ubiquitous 6SN7 dual triode for which audiophiles

will pay exorbitant sums of money (for certain variations of

manufacture.) In the USA, it's probably easier

(less expensive anyway) to find a 6F8G at about $20 to $50 (for

used/tested good) rather than to try and compete with the

audiophiles for a VR102/BL63 at over $100 a piece. |

Amateur

Modifications - Like the BC-348 here in the USA, there

are a lot of surviving R1155 receivers in the UK today. But,

also like the '348 in the US, a complete and all original R1155 is

a rarity and

difficult to find. The R1155 was available on

the British surplus market for very low prices starting in the

mid-to-late-1950s.

And, like the hams in the USA with the BC-348, the British hams bought the R1155 as an

inexpensive way to obtain a decent receiver and then "modified" the

R1155 to suit their needs. Most often the direction finding circuits

were entirely extracted from the receiver since they weren't going to be

needed but the space they had occupied on the chassis was going to be needed

for their ham mods. With the right side of the chassis nearly vacant, an AC power

supply was generally built into the receiver. There were other mods that were

published in the British ham magazines of the time that advocated even

further destruction of the receiver's originality. The result is that today, like the BC-348

in the USA, very few "complete and original"

R1155 receivers exist. |

|

|

A Minimally Modified Example -

Mods to SN:34471 SN:34471 appeared to be

very good looking example that was complete and original, that

is, until it was examined in detail.

Here's a list of the types of mods that might be found in almost

any R1155 receiver that seems to be "all original" and that

assessment is based on using photographs or a cursory visual

examination for the inspection process. Not that I'm

complaining! This receiver was very easy to return to

original. |

| 1. V1 & V2

Grid Leads Mod - V1, V2 and V9 were missing which

wasn't too surprising. A close look when installing a couple of

CV1099 tubes for V1 and V2 revealed

that the grid cap wires for these tubes were gone. Wire was

"cut" from junction of C56 and R57. New grid

leads made with rubber insulated wire to correct. 2. The grid lead for V9 was still

present but had been wrapped with friction tape to insulate.

Removed tape and installed grid lead on the 6F8G that was

installed for the V9 function.

3. Trailing

Ant Mod

- R62 (static drain R)

was disconnected from pin 2 of the P1 Jones-type receptacle.

This resistor was in place to drain static build-up from the

trailing wire antenna.

Resoldered R62 for originality.

4. HET OSC Mod

- It was noted that a couple of

non-original looking wires (bright orange and blue plastic

insulation) exited the BFO box on top of the

chassis. Tracing the two wires revealed that it was a mod that

parallel-connected an air variable with the HET ADJ condenser

with a non-original air variable C mounted in the METER BALANCE

position. This mod was to provide a front panel BFO control.

This mod resulted in a missing R51 (a 20K linear taper pot) that was for the METER BALANCE

circuit.

Luckily, the three wires that

were connected to R51were still present. Desoldered

orange and blue wires and removed. Removed non-original air

variable C. Installed vintage 25K pot and connected original

wires.

5. A

non-vintage 18.2K WW resistor added to the switched B+ in series

from HET switch to the BFO tube circuit. This may have been to reduce the BFO level (for

weak CW stations)

or it may have been to compensate for the addition of Mod #4.

Removed WW resistor and reconnected original wire to HET switch.

>>>

|

>>> 6. V9 Mods

- There appeared to be some modifications that were never

completed involving V9. A small audio output transformer was

mounted under the side rail. Only one end of the primary winding

was connected to pin 3 of V9. There were no other connections to

this transformer with the opposite end primary wire not being

connected to anything. The secondary was shorted together with a

jumper. Perhaps it was going to be used as a choke. The original

wire from pin 3 to L26 had been cut and removed. R65, a 10K

resistor, was disconnected from pin 5, one of the grid inputs on

V9. The jumper wire between V9 cathodes, pin 4 to pin 8, had

been cut. Installed new wire with rubber

insulation to replace missing pin 3 to L26 wire. Reconnected R65

and resoldered cathode jumper wire. 7. Multivibrator Speed

Switch - wasn't an original component. Made in

USA toggle switch.

Removed non-original switch and replaced with

an original R1155 toggle switch.

8. Nomenclature Plates

- I wondered about the gold color on the Band Change, MS,

Logging Scale plates and the SN plate. I closely examined each

and they are original. I believe the paint was worn off because

these are the most used controls and the radioman was probably

wearing heavy insulated gloves that tended to "scrub off" the paint and

"polish" the base metal. I think the serial number plate is

another matter. It appears original and was probably "over

cleaned" during an earlier restoration.

Luckily, these mods to SN:34471 didn't remove very much of

the original circuitry or too many original components. Return

to the original circuit and configuration was easy to accomplish.

More details further down this write-up in "Getting SN:34471

An Original Example R1155 Operational." |

|

Original Example

with Aluminum Construction |

|

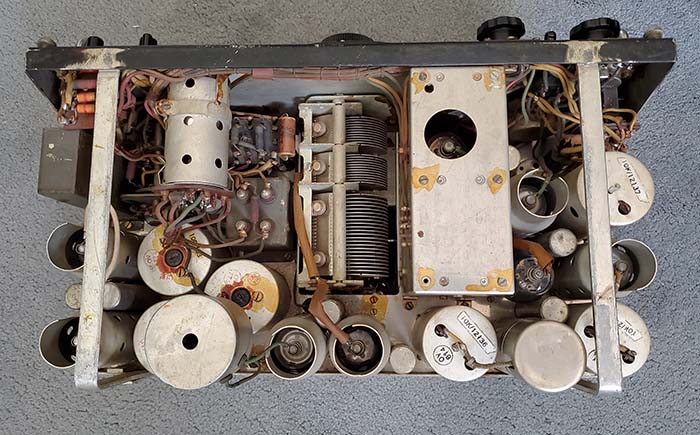

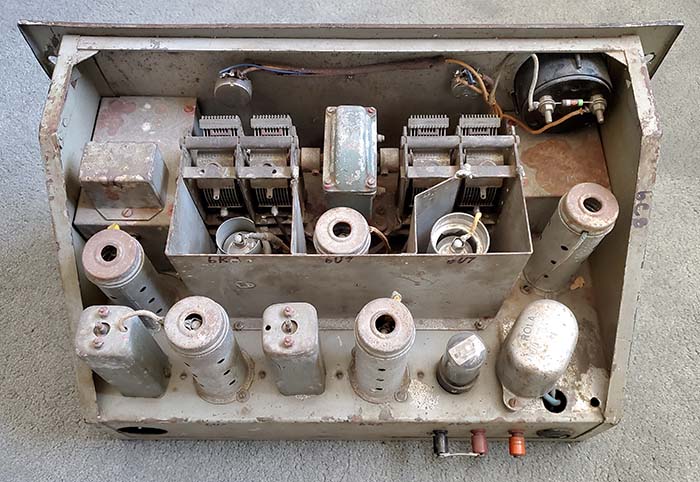

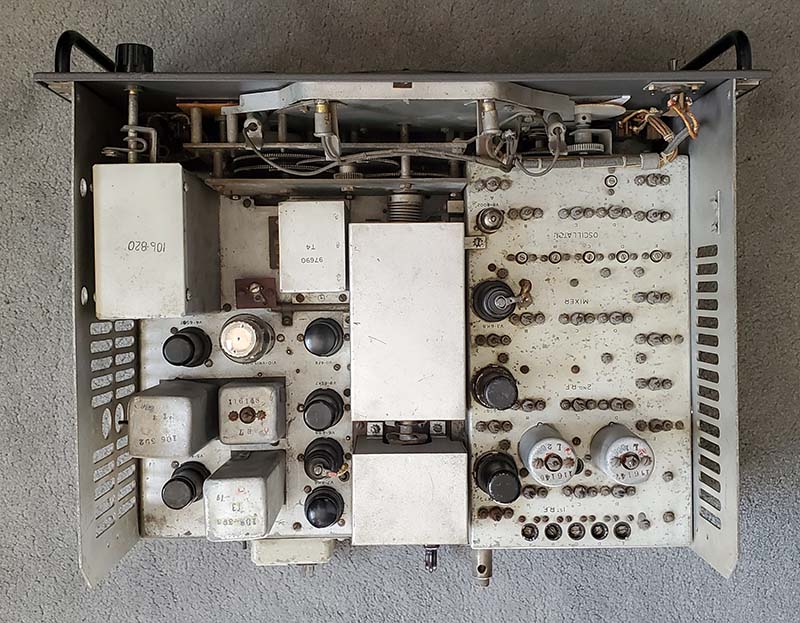

| Top of the chassis on SN:34471. The

construction is all aluminum. The cylinder that is

mounted over the MW RF coils is the MW filter

which is a wave trap network for 560kc. The two tubes on the far left

are the loop amp/multivibrator tubes. Behind the tuning

condenser are the RF amplifier and Converter tubes. In the shielded

compartment is the BFO/AVC tube. The upper most tube

to the right of the shielded compartment is the Detector, Meter

Limiter and Audio Output tube. The next tube down is the R-L

meter amplifier and to the right of it is the 2nd IF amplifier. The

tube with the shield cap is the 1st IF amplifier tube. The horizontal, panel-mounted tube is the

tuning eye tube. |

|

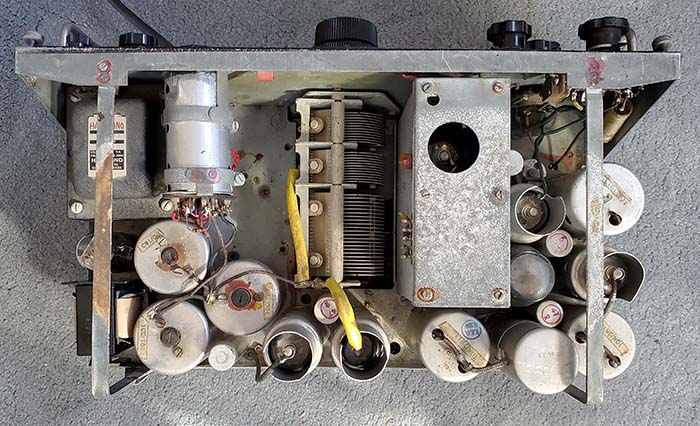

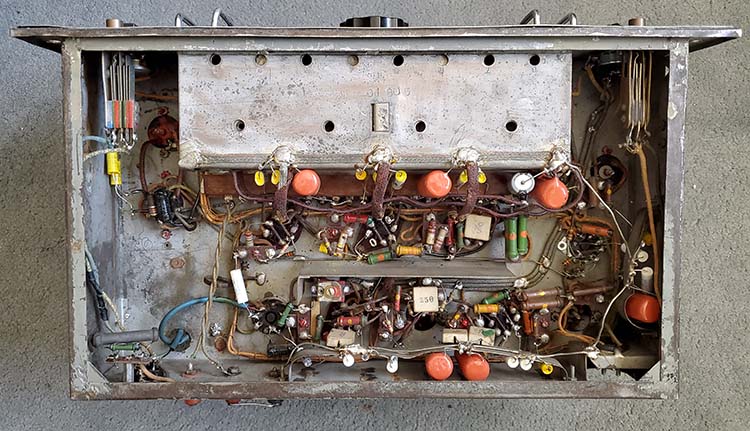

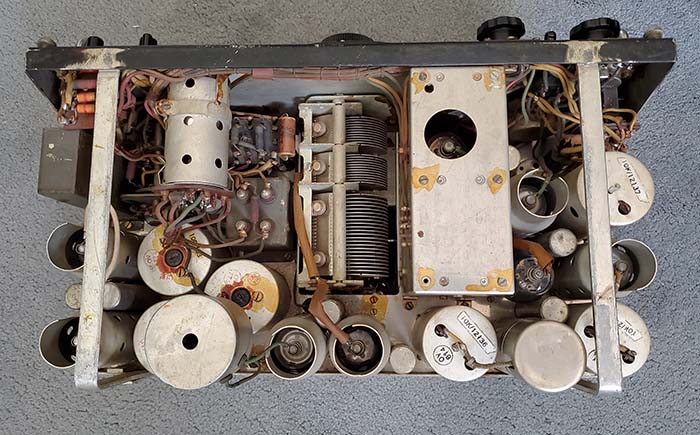

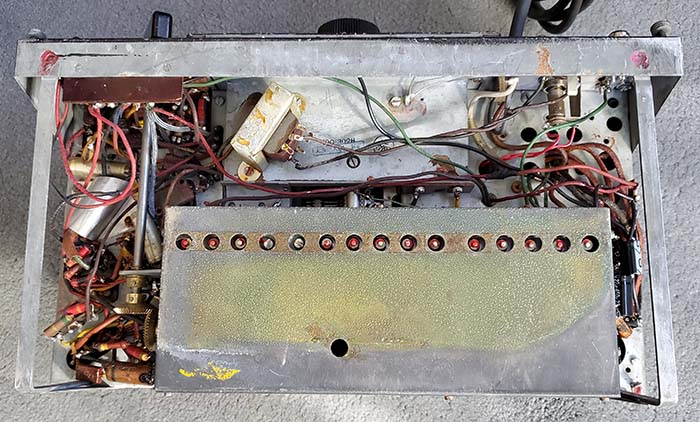

| Bottom of the chassis on the same

receiver. Full shielding for the HF RF section and band switch which are within the aluminum

shielded box. Note the right-angle gear drive for the band

switch (actually easier to see in the lower photo.) As can be

seen in this photo and the photo to the left, the

original wire used had natural rubber insulation that

does have a tendency to dry-out and become brittle. This

receiver was apparently kept indoors for its entire

existence since the rubber insulation is still pliable

and supple. Many R1155 will have already had some or all

of the wiring replaced as repairs or restorations. Other

receivers might need this done as part of the rebuild.

Note on the left rail that there are two drilled holes.

There was a small audio transformer (not connected into

the circuit) mounted there. |

|

|

Modified Example

with Steel Construction |

|

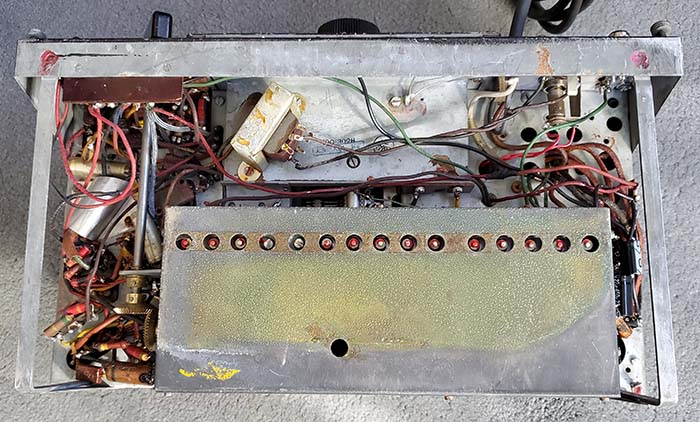

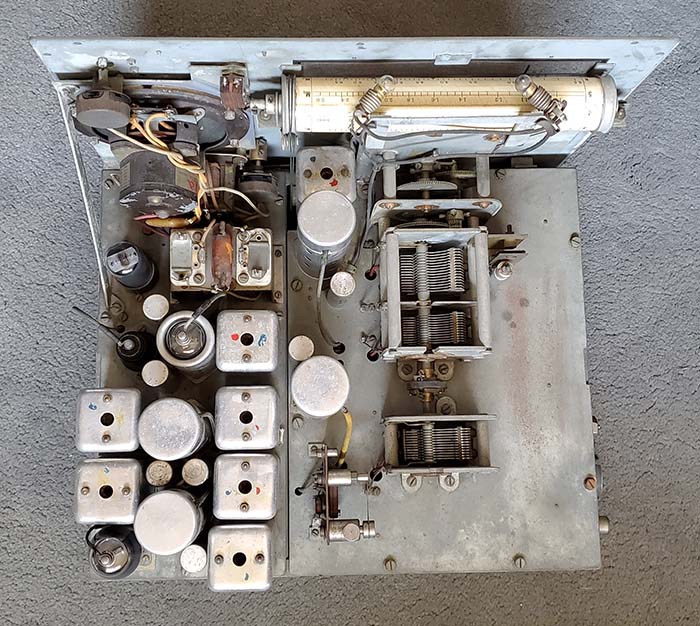

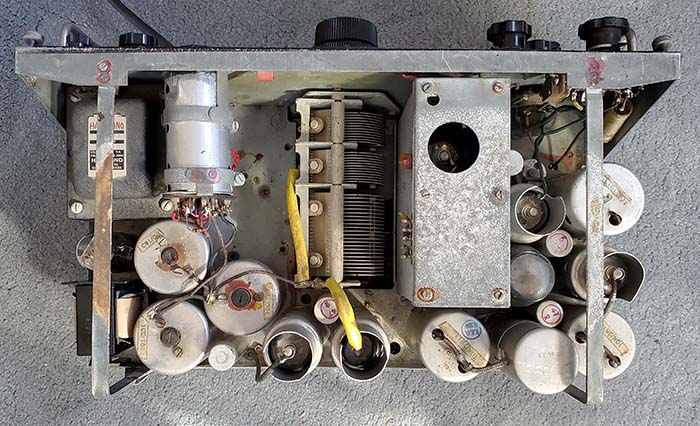

| This is the top of the chassis of

SN:68154 showing how the steel construction appears.

Note the corrosion on the cover of the BFO tube housing and the

rusted area on the left rail. Where the chassis can be seen it

has some spotting. This receiver has been severely modified.

Note the Hammond power transformer upper left and below it the

5Y3GT and the filter choke. Also, compare this chassis to the

one in the photo above (SN:34471) to note how many of the

original components are missing. The large glass tube to the

right of the BFO housing is the added 6F6 audio output tube. |

|

| Apparent is a strange yellowish

corrosion on the steel shield over the band switch

compartment. Compare this chassis photo to the one above

to note how much of the original circuitry is gone. The

transformer mounted upper center is the Lo-Z audio

output transformer that provides an 8 ohm output from

the 6F6 output stage. Much of the original rubber

insulated wire has been replaced in this receiver. |

|

|

A Ham

"Extremely Modified"

Example SN:68154 Here's a R1155

receiver that has had just about everything involving the DF

circuits removed

from it and even more done to the remaining circuits. Even the serial number

identification plate doesn't match the receiver. What makes it unusual is that

this receiver is the "steel construction" version so it wasn't

used on aircraft but was a ground receiver. |

photo above: R1155 sn:68154 is typical of the majority

of surviving receivers. Severely stripped of its DF circuitry

and "input-output" Jones connectors to install an AC power

supply. The actual identity of this receiver is questionable

since its chassis and panel are steel making it actually a "D"

version. It's unknown why the "A" version tag is installed. The good thing about this receiver is that it was

bargain-priced ($38+shipping.) Though its originality has suffered, this receiver has

been somewhat resurrected and is now operational as a receiver only. |

To the left is a R1155, tagged as SN:68154 and

ID'd as an "A" version. The receiver's ID/SN plate indicates

the receiver is a R1155A but it's built on a steel chassis with

a steel front panel and steel shielding. This receiver is

actually a R1155D which was the early steel construction

version. Even though the DF section was "stripped out" it

appears that there never was a MW filter installed indicating

the receiver is the "D" version.

The Mod Rundown,...

1. Removal of all DF

circuitry, wiring and components - All DF

controls removed. Much of the hardware was also removed and discarded. Most

original knobs gone.

2. Antenna input

- This is a brown bakelite binding post terminal-type that was

"hacked" into the upper right side of the panel.

3. MS (Master Switch) Relocation

- Of note is the vacant MS area. The switch was moved

to allow the installation of the power transformer which is

located directly behind the panel where the switch had been. The

MS was moved to the METER BALANCE (pot control removed) location (upper left side of the

panel) and only two positions were wired - AVC and Manual Gain with BFO

on.

4. Power Input Changes and Electrodynamic Speaker Intentions - The Jones connectors were

entirely removed and an aluminum plate

installed. The four pin tube socket had been intended for an electrodynamic

speaker with the field coil doubling

as the power supply filter choke. The AC power ON switch

is the only original type R1155 toggle switch. SN:68154 was

modified in Canada so the power transformer used for the AC

power supply was a 115vac primary type built by Hammond. AC

power cord exits out the front of the panel.

5. Lo-Z Audio Output with

a Boost - With the VR102 dual

triode R-L meter driver removed, a 6F6 audio output stage had

been added at that location. A Lo-Z audio output transformer was added after the

original Hi-Z audio transformer had been removed.

6. Logging Scale

- The

Fine Tuning logging scale was removed sometime in the past.

7. Cabinet Destruction

- Two one inch diameter holes were punched in the top of the

cabinet. Nine one inch diameter holes were punched in the right

side of the cabinet. A common hamster thought fallacy that the

onboard an AC power supply

and a high power audio section would get so hot that complete

cabinet ventilation was going to be necessary.

|

| Mod Makeover

- I had to perform a few minor repairs to get the receiver

operational but these were just small problems that had developed over

the years of moving and storing and then shipping the receiver (from

Arizona to Nevada.) The

majority of the serious rework was correcting the mod-design flaws and

basically making the mod changes a bit more professional-looking.

I replaced

the amateur-looking raw aluminum subpanel in the lower right section of the main panel with a

new black wrinkle

subpanel.

I also removed the old brown bakelite dual post antenna terminal

and filled the non-original holes with epoxy and painted over to

hide the fill. I added military-style Antenna-Gnd push terminals

on the new sub-panel (although for a Brit receiver they should have

had "A-E" and "E"

engraving.) I added the red

jewel pilot lamp because the R1155 has no visual indication

that the power is on (the dial is not illuminated.) I replaced the

1920s-era phone jack with a single circuit

phone jack with a

toilet seat cover that's marked "Speaker 2nd Audio" - both jack and seat were out

of the BC-342 junk box.

I eliminated the four pin tube socket and discarded the idea

of using an electrodynamic speaker. I rebuilt the AC power

supply to use a filter choke instead and to have the audio drive

a PM speaker. The mod had used a 5Y4G rectifier tube and it was

found to be defective. I rewired the socket to use a 5Y3GT which

is much easier to find and physically smaller. The defective

can-type multi-section electrolytic (not original) was removed

to have room to install the filter choke. I then used two new

axial-type electrolytics mounted under the chassis. I left the

AC power cable exiting out the front because any other exit route would

further destroy the already seriously damaged cabinet.

>>> |

>>> I had to leave the MS in the Meter Balance

location since the power transformer prevented moving it back to

its original location. I did move the HET wires from the MS and

repurposed a vintage toggle switch to now

separately operate the HET (BFO) from the correct location.

The "re-do" did require some rerouting of the "mod routed"

wires. Many of the wires had rubber insulation which has a

tendency of drying out and then falling off whenever the wire is

flexed. I had to replace several wires that were in this

condition. The dial cover was removed and thoroughly cleaned

which improved the transparency of the original convex plastic.

The dial scale was also cleaned which greatly improved the dial

appearance. A new gasket was made for the mounting interface.

Most of the vacant holes were fitted with control knobs even

though all are "dummy knobs," that is, just for appearance.

Since the receiver was far from original I painted-over the yellow

hand-painted

lettering.

Mechanically, the two-speed dial knob assembly needed

a complete overhaul in order for it to function as intended. The smaller

front

knob is 1:1 "fast tuning" and the larger back knob is 1000:1 "extremely fine

tuning." The conical drive wheels had been greased and the cork friction

gasket was also greased. Needless to say, the drive wheels didn't move

the reduction plate until all of the grease was removed and all

surfaces thoroughly cleaned. This two-speed tuning knob was a

constant source of problems when the receiver was in use during

WWII probably because the reduction drive relied on friction

only. By mid-WWII an improved replacement tuning knob was

available. However, not many R1155s had the improved two-speed

knob installed so this example does have the commonly

encountered,

older, problem-prone, original two-speed knob installed.

|

|

General Performance

- Overall, the R1155 performance results will depend on the

operator's expectations and experience with vintage gear, the operator's QTH and the antenna

used. The R1155 is a capable receiver as far as sensitivity is

concerned and a resonant or tuned antenna will allow excellent

reception of most HF signals. Audio is for phones but SN:68154 had a 6F6 audio

output stage added so it easily drives an 8Z loudspeaker. BFO

provides enough carrier for either CW or SSB copy and the

"extremely fine tuning" function allows easy tuning of those CW

or SSB signals. The tuning eye tube only functions on AM

signals. The IF bandwidth is

fairly broad and not really adjustable. For its use on an

aircraft during WWII, sometimes with the plane being shot at,

narrow bandwidth would have been a disadvantage. If the radio op

needed to change frequency under those conditions and was

searching for a homing beacon signal, a broad IF would make finding

such a signal easier. Also, at altitude the interior of the

airplane was cold and the radio op wore flight gear that

included insulated gloves which made any "fine tuning" nearly

impossible (sometimes it was a "gloves off" operation performed

as quickly as possible.) The lack of a crystal filter or other means to

narrow the IF bandwidth isn't surprising. For what is essentially a "one RF

amp, converter and two IF amps" receiver, the R1155 does a

surprisingly good job. Though, if up against the BC-348 with its "2 RF

amps, Mixer, LO, three IF amps and a Crystal Filter," the R1155

would probably come in second as a radio receiver in such a

comparison.

The R1155's desirability nowadays probably

isn't its performance as just a receiver. The original R1155, with

its ability to DF with its associated

rotatable loop antenna and sense antenna, its ability to drive an external R-L indicator meter and also

perform adequately as a radio receiver make the "complete and

original survivors" the most

interesting and desirable versions. However, the majority of R1155s

didn't make it past the hackers that, in their enthusiasm to perform yet

another

"surplus to ham radio conversion," have relegated most of these

historic receivers to

a "relic" status. |

The photo above shows R1155D SN:68154 after reworking was

completed. I think it looks a lot better than it did,...and now

it functions quite well, but just as a radio receiver. In car

collector parlance, one can think of SN:68154 as the "daily

driver" - kinda beat so you don't really care if it gets a

scratch or two. Then SN:34471 is the "all original, only trailered to

shows" example that looks really good but might not run all that

well. |

|

Getting SN:34471, An

Original Example R1155A Operational

The basic return to original was covered in

the section "A Minimally Modified Example" above. Here's

some more

work necessary to actually have an original example also become

functional. |

| Jones Plugs

- The original plugs were basically Jones style connectors.

Where they differed was how the cables were routed as they

exited the plug shell cover. Original British plugs had the cables exit out

the bottom of the plug cover. A cable clamp fitting was

installed on the bottom of the plug cover that further routed

the cable back under the receiver. Modern Jones plugs work and

fit perfectly but the modern plug covers have the cable exit

directly behind the plug at the center-back of the cover. To

make my modern Jones plugs look more like the originals I had to

do a few modifications. First, for the Loop Antenna plug, P3, I

used an eight pin male plug and removed the locating pin which

was slightly off from the original location and then also

removed four of the blade pins so P3 would be a four pin male

with a long body. The long body is necessary because inside the

back cover is a variable trimmer capacitor and a fixed-value

capacitor that connects to the pins of the plug. These

components were used to trim the airplane loop antenna, cabling and routing to

match the receiver loop input impedance. For all three modern plugs the cable clamps were removed

and then the rolled metal trim around the hole was

removed with a file. The back hole was then covered with a "butch

plate" made from .030" aluminum. The aluminum cover piece was

mounted to the rear cover using four 2-56 screws and nuts for

each cover piece. A new .437" hole was drilled into the bottom

side of each cover. Next, the "butch plate" covers were mounted, cleaned and

then painted black wrinkle finish. Rubber grommets were

installed into the bottom cable exit holes. I didn't install the

modern cable clamps since they were nothing like the originals

and wouldn't allow routing the cables directly back under the

receiver.

Wiring P1, P2 and P3 Jones Plugs

- P1 is the right-most Jones connector. This is the input access

for providing tube heater voltage or 6.3vac (originally 6.0vdc

in the aircraft which depended on the drop provided by the external

resistance unit used.) Also, about +230vdc for B+ and about -30vdc for

the bias needs. Additionally, antenna inputs for both the

trailing wire antenna (for MW reception) and the fixed antenna

(for SW reception.) A chassis connection is also required. The

audio output also is from P1. The audio is 5000Z and runs at

'phones level. All receiver voltage inputs and the audio outputs are

accessed at P1. P3 is just for the loop antenna input. The plug, as

mentioned, has a trimmer capacitor and a fixed-value capacitor

inside to match the entire loop and cable impedance to the

receiver loop antenna input. P2 is just for the Visual Indicator connections (the

"crossed-needles" R-L meter.) >>> |

>>> I couldn't find any vintage photos that showed how the

original cables looked. In all installations it appears that the cables

were routed under the receiver then behind the receiver up and

under the T1154 transmitter and then up to the T1154's lower

front panel connectors that are also Jones-type receptacles. The Visual Indicator and the Loop Antenna also appear to

connect from behind each of the devices. The antenna cables from

P1 usually connected to the antenna switching panel Type J.

Nearly all cabling is not really very visible in the original

photographed installations.

A Test Cable for P1

- I made the six wire cable about five feet long. Since this

operation was still in the "test mode" I didn't bother to

install a shield or to wrap the cable. Also, since this was for

test, I tied the two antenna inputs together. I connected the P1

Jones plug to one end and tinned the stripped and bare wire ends on the other end

of the cable. The tinned ends were for easy "test" connections

to the Lambda Model 25 bench supply that provides 6.3vac at 3

amps for the tube heaters and adjustable B+ that I set for

+220vdc. I also connected a small bench supply to provide -25vdc

for the bias voltage. I used a set of Western Electric 518W Hi-Z

'phones for audio reproduction. I connected the antenna lead to

an indoor ten foot "test antenna." Upon applying power I was

surprised to hear a good signal background noise through the

'phones with the receiver tuned to approximately 350kc. I

switched over to the AM-BC band and tuned in several stations. No hum and no distortion.

The VOLUME control is very noisy in operation, the HET OSC is way off

(from the mod that paralleled an air variable for front panel

BFO) and the "eye

tube" is black (well with some imagination, maybe just

perceptibly "dark" green.) All in all, a good "first test."

The "eye tube" is a VR103 (CV1103,) something like a 6G5 but with an

octal base. The eye tube in SN:68154 was somewhat dim but still

easily visible in average room illumination. I swapped the

relatively good VR103 with the dark tube from SN:34471. The HET OSC was just a blade screw driver adjustment. With the receiver

in MVC/HET operation the VOLUME control is a RF gain adjustment

and the noisy operation ceased. I added another wire to the

cable so I could separate the antennas. The trailing wire

antenna went to the "test antenna" since it was for MW coverage. I connected the outdoor wire, a

135' "T" antenna to the fixed antenna input for SW and was able to tune in hams on 40M and on

20M along with SW-BC stations in the 25M band. More to

come,... |

| Building a

Dedicated Power Supply for the R-1155 - Three

voltages are required to operate the R-1155. The tube heaters

can be operated on 6.3vac with about 3 amps of available

current. The B+ can be anywhere from +190vdc up to about +230vdc

with about 65mA of current available. A bias voltage of -25vdc

to about -30vdc is required also.

A filament transformer can be used for the tube heaters or a

power transformer with a filament winding rated at 6.3vac 3A

would also work. By elevating the CT of a full wave rectified B+

power supply, a negative voltage can be created for the bias

voltage requirement. This can be accomplished by connecting the

CT through a resistor to chassis. An adjustable "slider" WW

resistor could be used and then the bias voltage could be

adjusted for best performance (the bias level needed is

dependent on the level of B+ used.) The B+ power supply

filtering must have the negative connections to the CT which is

also B- for the input filter capacitor. If choke input is used,

then the first filter capacitor negative should be connected to

B-/CT. The filtering used will determine the

negative connection of the second filter capacitor. With

pi-filters, the second negative should connect to chassis, if

the filter is dual-section, then the second capacitor negative

should connect to B- and the third capacitor negative should

connect to chassis. |

Parts Located

- I bought a small collection of R-1155 parts from an EBay

seller in Britain. This little collection in a plastic bag

supplied an original plug-retaining post for the left side of

the plug bay. There were also a few knobs and other small

hardware spares that might be needed in the future. |

|