|

Signal Corps U.S.

Army - RCA Manufacturing Company, Inc.

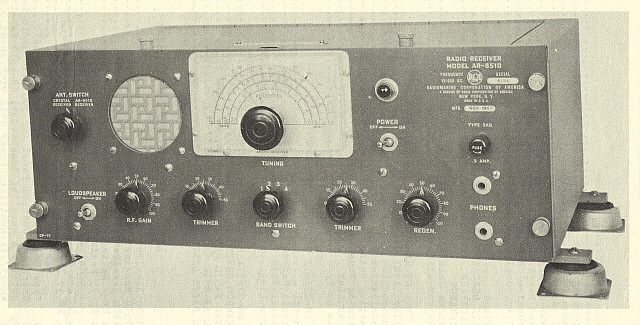

BC-224 Series and BC-348 Series

Various Other Contractor Companies

| If ever there was a WWII military aircraft receiver that did

"so much, so well,

with so little," it was the BC-348. The double preselection

superheterodyne receiver provided two TRF

amplifiers, three IF amplifiers, Crystal Filter, front panel adjustable BFO, AVC-MVC,

direct frequency readout on an illuminated, "band-in-use" masked

tuning dial and an

Audio Output stage that could be selected internally for 300Z or 4000Z

loads. Unlike most early aircraft receivers, the BC-348 was entirely "self-contained." All that was required

was to connect the receiver to the +24vdc aircraft power buss, hook up

the antenna, hook up the remote standby line and plug in the 'phones. The

total weight of the receiver was about 35 pounds. Well-over one hundred

and fifty thousand

BC-348s were built during WWII making them one of the most common WWII

aircraft receivers out there. It's unfortunate that over the past seven

and a half decades hams (and surplus dealers) have managed to "cut and hack" almost

every

surviving example making it nowadays a real rarity to find an all-original,

dynamotor-operated BC-348. |

|

BC-224-H

- 1942 |

|

|

RCA introduced the

BC-224 Aircraft Receiver in 1935. It ran on the then popular 12 volt

power systems used in most aircraft. The initial version of the BC-224

had the tuning dial on the left side of the front panel. This version is

usually designated as the BC-224-A and the number produced was very

small which was typical for pre-WWII military contracts. As aircraft

power systems evolved, 24 volts became the standard voltage and that

required changes to the radio equipment that was going to be installed in the newer

airplanes. RCA redesigned the BC-224 to operate on 24 volts and this

receiver was designated as the BC-348. With the redesign, both types of

receivers had the tuning dial relocated more towards the center of the

panel. The BC-224 continued to be built

for installation into earlier aircraft while the BC-348 was produced for

modern aircraft installations. Both receivers were built by RCA

Manufacturing Co., Inc., a division of RCA-Victor that built all of the

commercial and military radio equipment for RCA. When WWII

began, several other radio companies became contractors for BC-348

construction,... Belmont Radio, Wells Gardner & Co., Stromberg-Carlson, to

name a few. Only one contract for BC-224 receivers was built by another

company other than RCA Manufacturing Co., Inc. and the last contract for

the BC-224 appears in 1942. The BC-348 was produced through WWII and

total quantity produced is certainly well over 150,000 receivers (over

50,000 receivers alone were produced by Wells Gardner & Company on just

the "Q" model contract.)

|

The BC-348 operates on

24-28vdc with the high voltage (~+220vdc) provided by an internal

dynamotor. It's quite likely that well-over 150,000 BC-348 (total of all

versions) were built during WWII by many different

contractors building many different versions within that time period.

The circuit used eight tubes with the heaters originally wired in

series/parallel for 24vdc operation (each of four 6 volt tube heaters in

series would operate on 24vdc.) The early circuit provided two RF

amplifiers, a Mixer, a Local Oscillator, an IF amplifier stage, a

combination 2nd IF amp and BFO, a combination 3rd IF amp and

Detector/AVC followed by a type 41 audio output stage (this was changed

to a 6K6 in some versions.) These versions will have a 991 neon lamp

acting as a regulator on the local oscillator and an antenna trim

control. Construction makes use of four component boards resulting in

extensive use of wiring harnesses. The Crystal Filter and BFO are in

fully shielded cans. This early version is usually referred to as the

"Grid Cap" version since these types of tubes are used. This early

version was difficult to work on and was expensive to build. To reduce

costs, the Q, N and J versions were introduced. These versions

eliminated most of the component boards and used "point to point" wiring

to reduce costs and ease rework. This version is called the

"Single-ended Tubes" version since "non-grid cap" tubes are used. The

later circuit used two RF amplifiers, a converter stage, three IF

amplifiers, a duplex diode/triode provided Detector, AVC and BFO

functions and a 6K6 provided the audio output. The later versions

eliminated the shielded Crystal Filter, Antenna Trim control and the

fully shielded BFO. The audio output impedance was internally selectable

at "low Z" which was around 300 Z ohms or "high Z" which was around 4000

Z ohms (on later versions.) Some BC-348s will have a decal on the front

panel indicating if the "low Z" was optioned. The dual dial lamps were

adjustable for brightness and were wired in series through a

potentiometer and fixed resistor. Frequency coverage was from 200-500kc

(not on the B or some C versions) and 1.5-18mc. The military considered the

two versions of the BC-348 to be interchangeable with virtually no

difference in performance and operation.

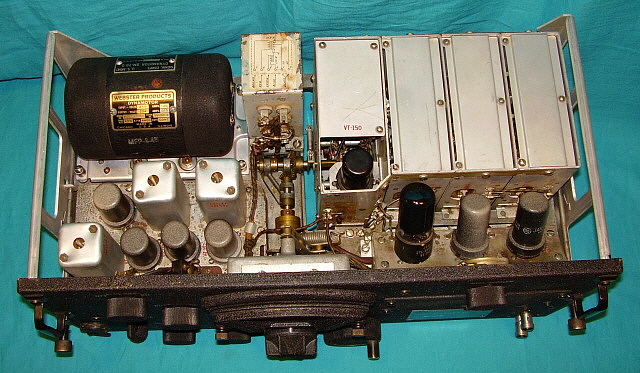

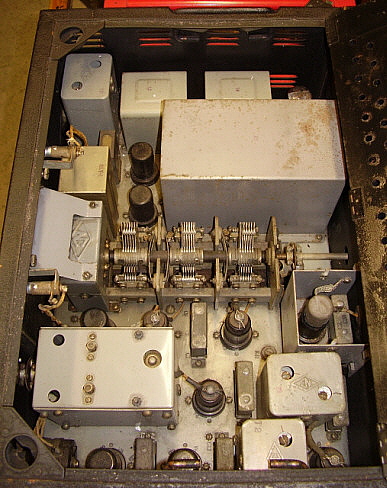

photo left:

Top of the RCA Mfg. Co. BC-224 chassis which is virtually

identical to all of the "Grid-Cap Tubes" versions of the BC-348

chassis. Note that this BC-224 does have the proper DM-24

12-14vdc dynamotor installed.

|

| A selectable crystal filter

was also included in the circuit. If working correctly, the

crystal filter can narrow the IF bandwidth to about 1kc wide,

which counters the popular contemporary opinion that the

BC-348's bandwidth is "broad as a barn." A correctly operating

crystal filter can be a valuable QRM-fighting tool,...even on AM

Voice. However, another option is to try and "dodge the QRM" with off-frequency tuning. Most SSB signals

are about 2.5kc wide consisting of one sideband of transmitted

information and no carrier. An AM signal is usually 6.0kc wide and, being

double-side band, information is in each sideband along with the

carrier. It's quick

and easy to tune off frequency (either above or below) a few

kilocycles, drop the SSB QRM off the edge of one sideband or the other and

still recover enough AM audio for good copy. This is the method

I use most often to dodge QRM using any type of vintage

receiver, not just the BC-348. The Crystal Filter can be used

for more severe QRM or when the QRM is on both sides of the

desired signal. Tune the

AM signal "on the nose" and the bandwidth will be significantly

narrower. Also, another thing to try for severe QRM is to go to MVC and only use enough

VOL (RF Gain in MVC) to allow copy.

When the receiver was

installed on its FT-154 shock mount and installed in the

aircraft, an eight pin Jones plug (SO-143) mated with a receptacle

(PL-103) and

cable that exited from the rear of the mount containing the

28vdc input, the remote stand-by relay function and an audio

output line. The BC-348 was generally interconnected with the

transmitter to control boxes allowing the transmitter's control

relay to provide antenna switching, receiver stand-by and

providing side tone monitoring which allowed for full "break-in"

keying. Since there are so many variations, military collectors

have generally divided the BC-348 into two groups, early types

(B, C, H, K, L, O, P & R) with grid cap type tubes (usually

called the "Grid Capped

Tubes" version, or GCT) and the later versions (J, N & Q) with

single-ended tubes (called the "Single-Ended Tubes" version,

or SET.)

Most of

the very early versions (B and C) were rebuilt into later configurations,

especially to add the 200-500kc band. These were rebuilt by

Belmont Radio and re-tagged as

"R" versions. Many different contractors

built BC-348s but Wells Gardner & Co. probably built the greatest

quantity of receivers and is the most commonly seen

manufacturer.

|

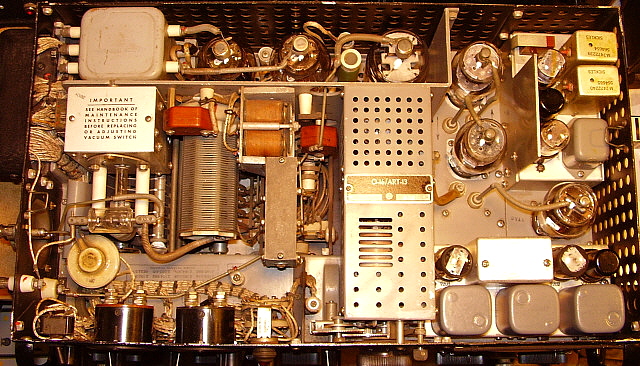

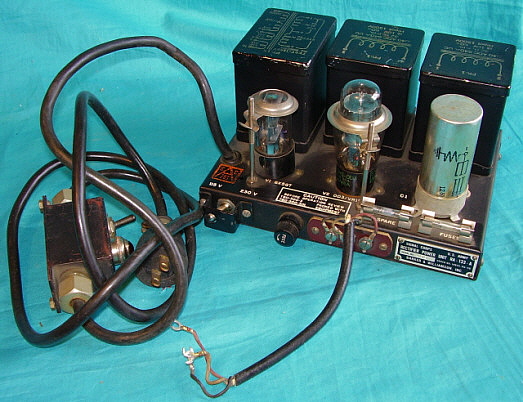

photo above: RCA Manufacturing Co. BC-348-C -

earlier "Grid Cap Tubes" version - ca: 1941. This

BC-348-C does have the original style DM-28 dynamotor installed

and the receiver is operational. |

|

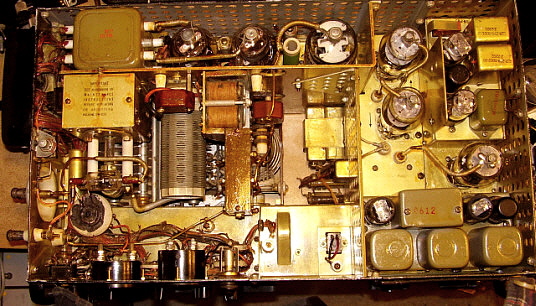

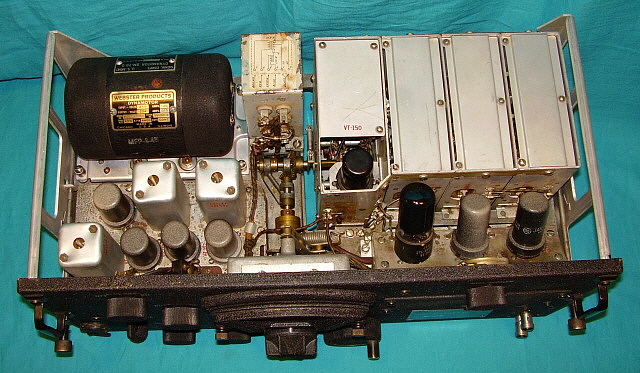

photo above: Wells Gardner & Co., BC-348-Q 1943

- this example is dynamotor operated. This

one WG contract alone produced over 50,000 receivers. Note that these

"Single Ended Tubes" versions eliminated the "ANT. ALIGN."

(antenna trimmer) control that was located above the Antenna and

Ground input terminals. Many other cost reductions will be found

inside the Q, N and J versions. However, the great performance

is retained and these receivers are very easy to do any rework

to. |

A History of Hacking

- The

BC-348 became available as surplus almost immediately following

WWII and was easily available for a couple of decades from many

surplus dealers. Early purchases offered the receiver NOS

in the original box. This allowed hams the ability to purchase a

great performing receiver at a reasonable price - still in the

crate for about $100. Many surplus dealer offered "AC power

supply conversions" for as little as $15, so the buyer didn't

have to do the work. The down side is that the dealers used the

cheapest parts available and their installations show that

little engineering thought (neither electrical nor mechanical)

was applied to their AC conversions. Today it's almost

impossible to find a BC-348 that hasn't been modified.

Typically, the dynamotor and filters were removed (and

discarded) and an AC power supply was built onto the then vacant

dynamotor chassis. Tube heaters were rewired for parallel

connections. This mod was fairly simple and usually didn't

compromise the receiver's performance too much (other than

adding some hum to the audio output if the power supply wasn't

designed correctly or wasn't well-filtered - which most

weren't.) Unfortunately, most of the dealer power supply mods

used a separate AC power toggle switch that resulted in a

non-original hole on the front panel.

Purists can't blame the

just hams for shoddy mod design and workmanship because the

dealers were actually charging the purchasers of the surplus

BC-348s for the opportunity to destroy the originality of

thousands of receivers. Additionally, all of the

dealer-installed power supplies were just Pi-network filtered

and as cheaply made as possible. Dual section filtering is

necessary for proper hum reduction in the BC-348. Also, not

realizing that there's a B- return for audio grid biasing, many "ham-ster modifiers"

grounded negative leads on filter caps causing rampant hum in

the receiver audio. Certainly the

"ham-ster" destruction of many of the BC-348 receivers was

popularized by CQ magazine and their "Surplus Conversion

Handbook" (there were multiple editions) in which page after page of "cutting and hacking"

examples were presented. Every page seemed to promote the idea that the BC-348 needed

"ham-level engineering" (after all, what did

professional radio engineers that worked in the major radio

corporations know about ham radio?) Adding an audio

output section was a common mod. After all, what ham owned, or could

afford, any sort of impedance matching transformer when they

could build the mod using "junk box parts." The audio output mod

called for the removal of the original audio output transformer

which makes finding an original audio transformer today somewhat difficult. Removal of the 8-pin Jones plug power

input connector or adding a useless S-meter were also common mods.

|

|

Additionally, many hams would sometimes drill the

case with lots of .25" holes thinking the receiver needed extra

cooling because of the added AC power supply rectifier tube.

Somewhere along the line of destruction, the receiver base

mount (the FT-154) always seemed to have been removed and

discarded. Since the receiver's engagement pins presented a

problem for "mountless" BC-348s, sometimes hams would drill

out all of the pop-rivets and remove the entire receiver base

and then add rubber feet to the bottom of the cabinet. Of course, this ruined the cabinet

for future use if the FT-154 ever turned up.

Decades of "ham-ster mods" have pretty much made an "all

original" BC-348 a true rarity. Of the well-over one hundred

and fifty

thousand built during WWII, few examples have made it to the

present time without some type of modification. However, with

diligent searching it's still possible to find unmolested

examples. However, not so rare and usually not so pricy are the

receivers that just had the AC power supply thoughtfully and carefully added.

These examples usually aren't too difficult to restore back to

proper operating condition. The Grid Cap Tube versions have many Micamold-brand capacitors that

will require replacement but the Single-ended Tube

versions eliminated these troublesome capacitors and many of the

SET versions can operate quite well on original components. Both

types of BC-348s are great performing receivers if restored to

original or when conservatively modified (a properly designed AC

PS only.) A thorough and accurate IF-RF alignment and

repair of the crystal filter are absolute necessities for top performance

(and must be done before any critical comments regarding IF

bandwidth are even considered.)

If you're interested in restoring your BC-348

or BC-224 receiver back to its original configuration with the

installation of the correct DM-28 or DM-24 dynamotor, go to our

web article "Rebuilding the BC-348 Family of Receivers" This

article tells you about all of the "pitfalls" that might await

you in this seemingly easy project. Also includes information on

other aspects of the restoration of these fine performing

receivers, such as building (or re-building) a minimally

invasive AC power supply that operates the receiver correctly.

Although the proceeding write-up

seems to imply that original dynamotor operation for the

BC-348 results in best performance, the receiver will also operate

just as well (perhaps better) on a correctly designed and properly installed AC power supply. |

photo above:

Inside the BC-348 "Single Ended Tubes" version. Note that the

shielded cans in the IF section has been reduced from six to

only three cans. Many other cost-reduction differences can be

found when comparing the construction of the SET version to the

GCT versions of the BC-348 receivers. Dynamotor is the DM-28

24-28vdc operation. |

|